Using penetrant testing to inspect stainless steel pipes for stress corrosion cracking and welds for cracks can be a slow job. Many pipes are rough, dirty, or painted. Before penetrant testing can be used, the pipes must be smoothed and cleaned. If they’re painted, it must be painstakingly stripped off and the pipe later repainted. Luckily, there’s a better way.

Here are 6 advantages of the MagnaFORM™ eddy current array (ECA) probe over penetrant testing.

1. No more paint removal and repainting

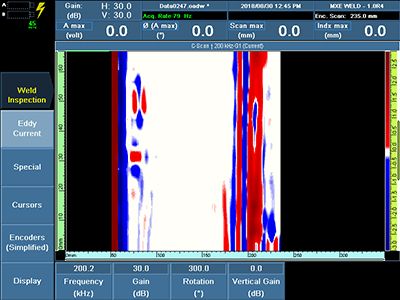

The MagnaFORM probe works with the OmniScan® MXE flaw detector to deliver reliable imaging through paint—no stripping or repainting required. This enables you to get the job done faster.

C-scan image of SS304 with 0 mm of lift-off |  C-scan image of SS304 with 3 mm of lift-off |

5. More coverage = faster inspectionsThe MagnaFORM scanner can cover up to 65 mm (2.56 inches) each scan, helping you get the job done fast. |  The MagnaFORM probe on a weld |

6. Won’t wear you downThe probe has replaceable wedges and built-in wear protection that will last you for an estimated 22 kilometers (13.7 miles) of inspection. |  The MagnaFORM solution includes the probe, scanner buggy, and 5-meter cable; the lift-off compensation software is loaded on a flash card and is used with the OmniScan MXE flaw detector |

Related Content

Tired of Removing Paint to Inspect Welds?

Video: Setting Up and Calibrating the MagnaFORM Probe for Carbon Steel Weld Inspection

Eddy Current as an Alternative to Magnetic Particle Inspection for Carbon Steel Welds

Get In Touch