Portable and benchtop X-ray diffraction (pXRD) analyzers can play an important role in the exploration and analysis of manganese (Mn) nodules. These deep-sea deposits contain high concentrations of valuable metals, including nickel, cobalt, and copper, as well as significant amounts of lithium, vanadium, molybdenum, and yttrium, making them valuable for future extraction in many industries.1

The search for these metals is critical to mineral exploration and mining companies, as many current and future electronics will depend on both these essential metals and some rarer metals. Because these polymetallic deposits contain a very large quantity of both groups, they possess a potential for huge economic viability. Additionally, as these nodules are nearly 100% metallic ore, there are no toxic tailings or mine waste during extraction.2

Figure 1. Location of all known Mn polymetallic nodules, with the five zones of most likely potential industrial exploration outlined in red. Source: National Centers for Environmental Information3.

While commercial extraction and mining has not yet been implemented for a variety of reasons, the high potential economic impact of these deposits cannot be ignored. In order to properly develop this technology, a way to characterize these nodules in the field must be used.

Elemental Analysis of Deep-Sea Nodules Using Vanta pXRF Analyzers

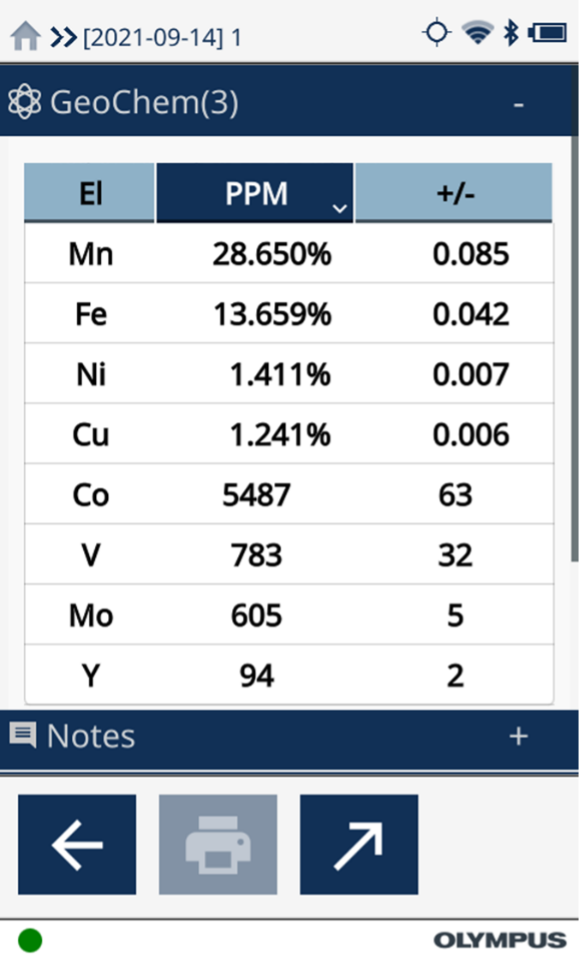

An Olympus Vanta™ pXRF analyzer can identify and quantify nearly every element between magnesium (Mg) and uranium (U), including the high-value first row transition metals, such as vanadium, nickel, copper, and cobalt, and other high-value metals such as molybdenum and yttrium. Other valuable materials, such as near rare earths and iron ore, can also be easily and readily quantified.

Mineral Identification of Manganese Nodules Using Olympus pXRD Analyzers

The Olympus TERRA™ II XRD analyzer is the successor to the world’s first commercial battery-operated, portable XRD instrument. Together with the BTX™ III benchtop XRD analyzer, these pXRD instruments can identify and quantify tens of thousands of various minerals, synthetics, and biologic phases in a single sample. Users can determine the grade, purity, and quantity of specific types of metallic ore in real time onsite, regardless of the chemistry and orientation.

Figure 2. Inline calculation on the Vanta pXRF analyzer of highvalue metals in Mn nodules.

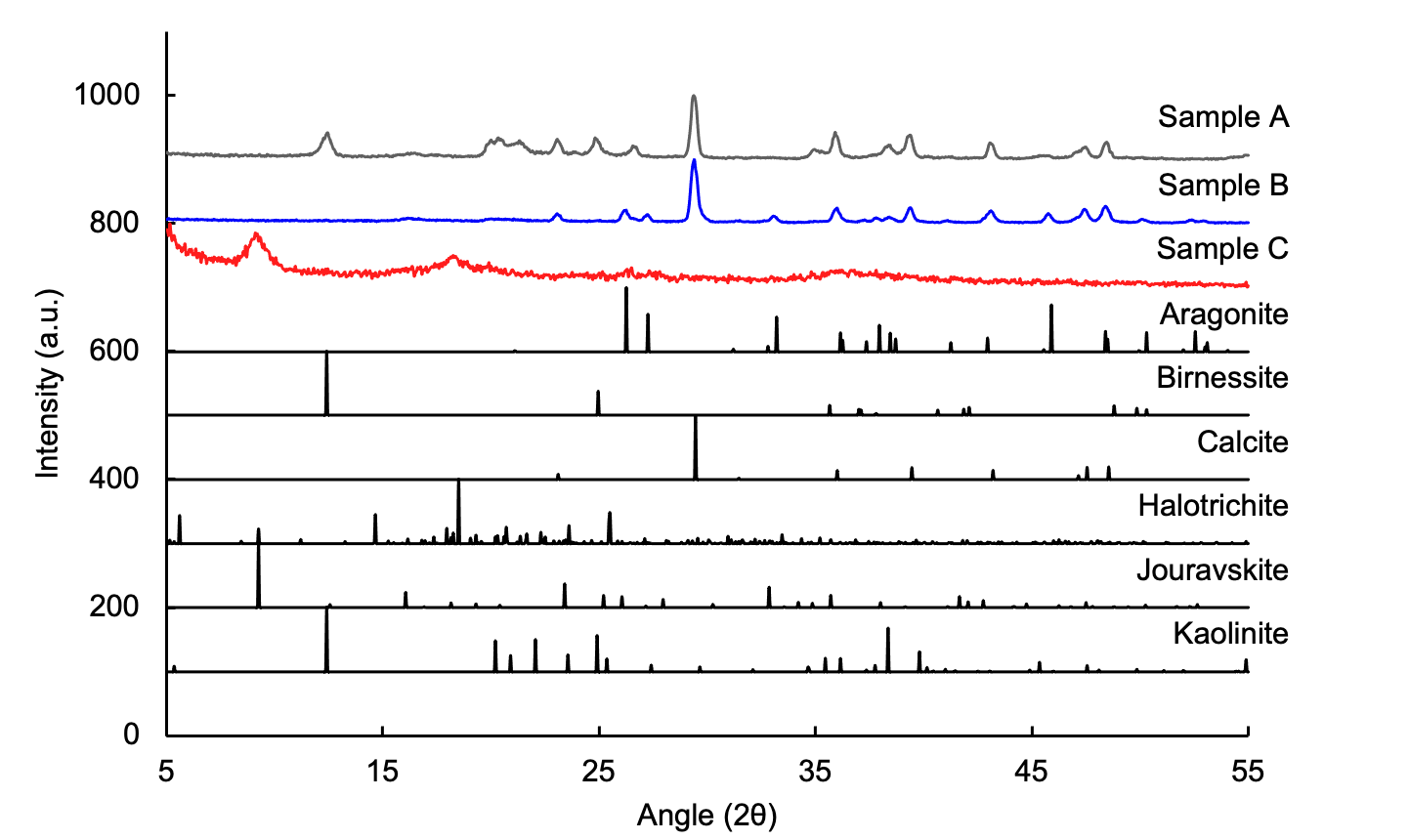

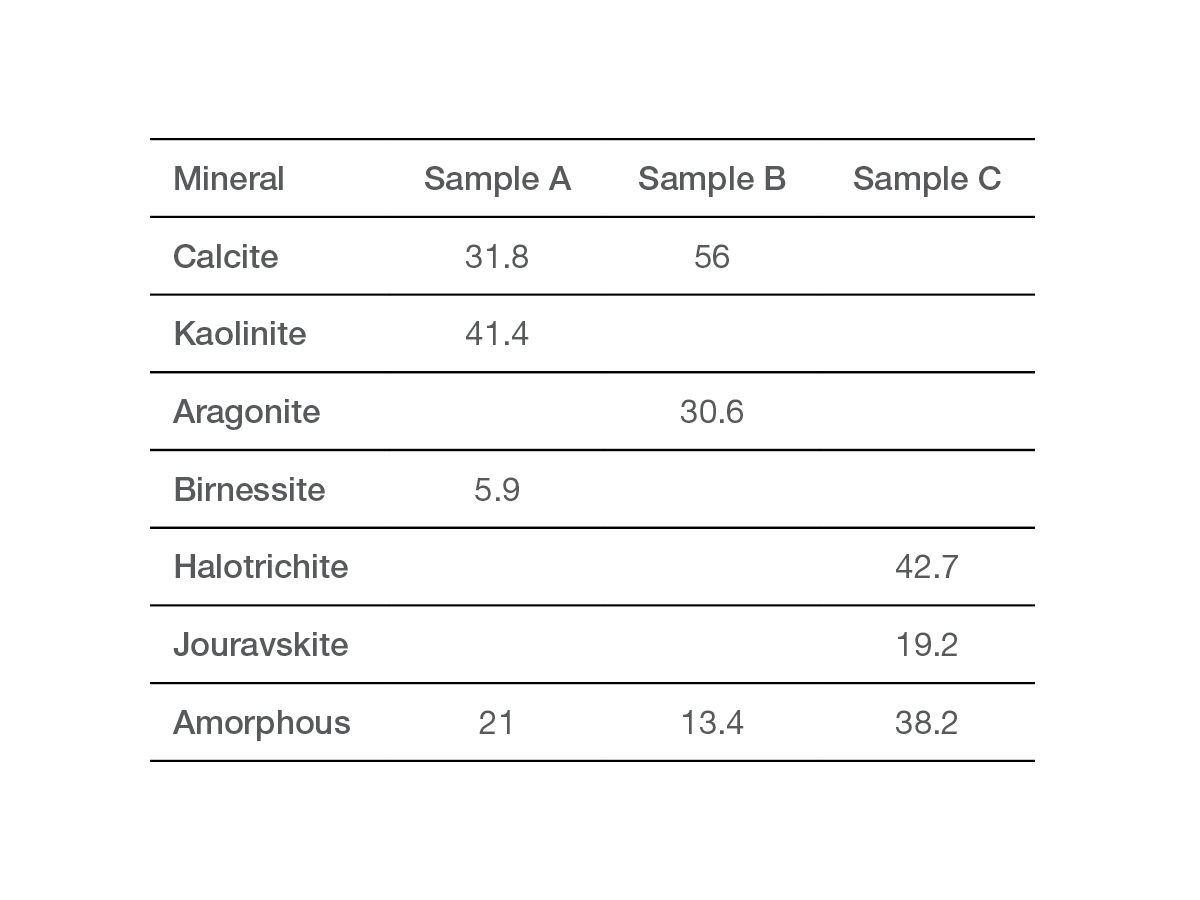

As shown in the diffractogram below, Olympus pXRD analyzers can quickly identify various phases in deep-sea manganese nodule samples. Each component of the sample can be identified and quantified in real time using the integrated SwiftMin® automated phase ID and quantitative software, or with standalone software packages such as XPowder software. These options make it even easier and faster to quantify phase information and mineralogy.

Figure 3. Diffractograms and quantification taken from the Cu-anode BTX III analyzer of three different deep-sea manganese nodules, some of which were taken from the Clarion-Clipperton Zone (CCZ). Each nodule contains a variety of minerals; the diffraction patterns for the dominant phases are shown.

Users can process this information on-site and in real time to better understand the composition of nodules without the need for expensive and slow laboratory testing. Nearly any naturally occurring phase can be identified and quantified using this technique, including common manganese nodule minerals such as birnessite or todorokite, hydrated sulfates such as jouravskite and halotrichite, and other minerals such as aragonite, calcite, and kaolinite.

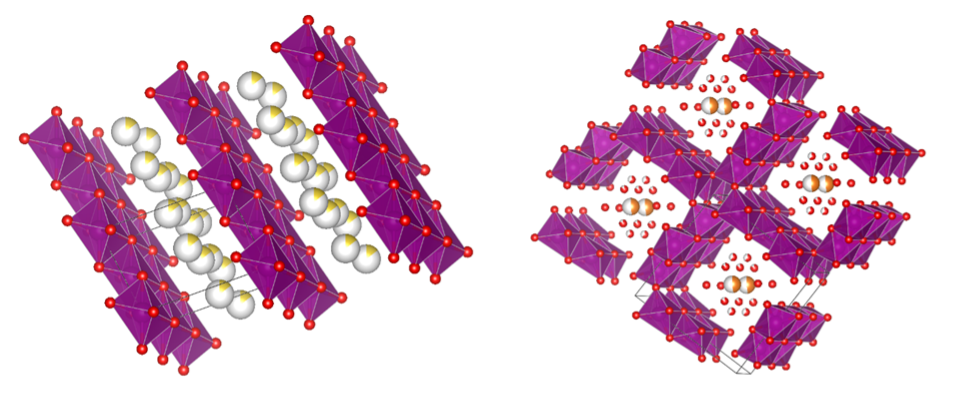

Figure 4. 3D structure of birnessite44 (left) and todorokite55 (right), which are common minerals in deep sea nodules.

- Fast acquisition: go from sample prep to analysis in minutes

- Virtually maintenance-free: runs without the need for compressed gas, water cooling, a secondary chiller, or external transformer to decrease downtime and costs

- Easy sample prep: simple mortar-and-pestle process can be done by operators of all experience levels in the field quickly and without complex equipment

- Small sample holder: only requires 15 mg of material compared to the large batch required for conventional XRD

References

- McKelvey, V. E., 1983. Analysis of the World Distribution of Metal-Rich Subsea Manganese Nodules. US Department of the Interior, US Geological Survey.

- International Seabed Authority, 2010. A Geological Model of Polymetallic Nodule Deposits in the Clarion-Clipperton Fracture Zone. ISA Technical Study Series, International Seabed Authority.

- Frazer, Jane and Mary Fisk (1981): Scripps Institution of Oceanography Ferromanganese Nodule Analysis File - IDOE Portion. National Geophysical Data Center, NOAA.

- Post, J.E. and Veblen, D.R., 1990. Crystal structure determinations of synthetic sodium, magnesium, and potassium birnessite using TEM and the Rietveld method. American Mineralogist, 75, pp.477-489.

- Post, Jeffery E. and Bish, David L., 1988. Rietveld refinement of the todorokite structure. American Mineralogist, 73, pp.861-869.