![]()

通常需要对成批的卷钢进行检测,以了解它们是否符合厚度规格。传统的测量仅限于卷钢头部的切割边缘。而超声厚度测量仅从卷钢暴露在外的一侧即可对卷钢整个宽度上的厚度进行监测。由于从卷钢边缘到中心的厚度变化可能高达0.05–0.10毫米,因此钢材加工厂通过使用小型超声测厚仪可以获得很大的收益。

用于检测金属卷材厚度的设备

金属卷材厚度检测的设备选择取决于所需的精度。更高的精度可以通过组合使用精确测厚仪和特殊探头来实现:如38DL PLUS超声测厚仪或装有单晶软件的45MG超声测厚仪,与20 MHz(M208)或10 MHz(M202)延迟块探头的组合。通常,这些超声测厚仪与M116接触式探头组合使用时的校准精度为±0.01毫米。如果在优化情况下使用M208或M202延迟块探头进行厚度测量,则超声测厚仪在高分辨率模式下的校准精度可达±0.008毫米或更高。还可以使用水浸式探头对卷钢进行连续在线厚度测量。

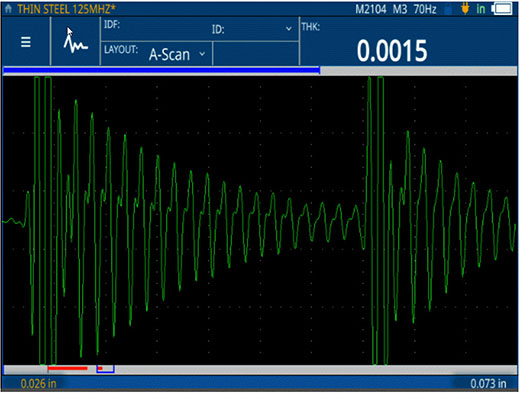

对于厚度小于0.203 mm的薄壁应用,建议使用72DL PLUS高频超声波测厚仪。作为一种高速仪器,72DL PLUS超声测厚仪的波形更新速率为60 Hz,测量速率可达2 kHz。这款测厚仪配备一个很大的全彩触摸屏,从不同角度都有很好的可视性,并支持无线局域网和蓝牙功能,可实现现代连接和集成。 右侧的图像显示的是使用72DL PLUS超声测厚仪和M2104(125 MHz)探头测量0.0381 mm钢板的波形示例。 |  |