Surface mining often entails the use of large trucks and shovels including massive Dragline excavators in large scale operations to remove overburden to access coal and other deposits of desired resources. Due to the size of this equipment many of the components are very thick resulting in challenging applications for ultrasound. In addition the preferred test methods are with the components in place and in operation which can mean limited access to the areas that need inspected. Phased Array can offer many benefits to these inspections.

Shaft and Pin Inspections

There are many shaft and pin components throughout an excavator. One critical component is the Swing shaft. There may be multiple of these components throughout a single excavator. Common lengths can be 200” plus and diameters of 22” or more. With the component in place there is limited access to the multiple areas that may require testing for fatigue cracking and other defects. Conventional ultrasonics often utilize multiple angled wedges to inspect as much of the component as possible. Once defects are found the shafts are often removed and a complimentary 0 degree inspection from end to end of the shaft is conducted to further analyze the nature and extent of any defects. There are often many holes and other obstacles for a single beam 0 degree inspection. Areas of prime interest include known stress areas, tapers and reductions of diameter areas. Because Phased Array offers multi-angle inspections from a single probe the limited access inspection area can be inspected much better and images and data can be stored if defects want to be monitored.

Swing shaft in place and partially removed

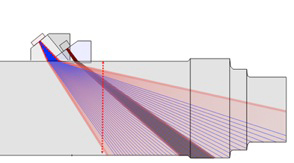

Conventional and Phased Array Angle Beam Coverage. Red line shows possible limited access when component is in place

Inspection i the field after shaft removed

|  |

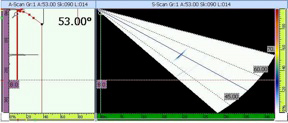

Image from defect free shaft (corner of taper show) and fatigue cracked shaft

|  |

Related Shafts and Pins throughout a Dragline Excavator

Equipment Used

OmniScan SX or MX2

- Portable for easy access inside cramped area of excavator

- Conventional, Phased Array and TOFD capable

- Manual or encoded data

Phased Array Probes and Wedges

- Vary on application

- 2.25 MHz common frequency

- Shear and flat wedges

- Contact wear faces for long 0 degree metal paths

Optional Software and Accessories

- OmniPC post analysis software

- Small Mini-Wheel Encoder