Olympus at MRO Europe 2021

Showcasing cutting-edge tools for reliable aircraft inspection

We would like to thank all our Olympus employees for showcasing the latest in aviation inspection at MRO Europe 2021. Most of all, thank you to the organizers and all our attendees who helped make MRO Europe 2021 so successful.

It was a great opportunity to meet the aviation maintenance community and fostered some interesting discussions with many of you. We hope that you felt the same!

While MRO Europe may be over for 2021, Olympus will continue to remain dedicated to providing high quality inspection equipment that minimizes aircraft downtime and streamlines the inspection process.

To find out more about the aviation equipment Olympus offer and discover informative webinars, blogs, and articles, please visit our industrial solutions homepage or see our content recommendations below.

Our aviation content recommendations:

Aerospace Inspection Solutions infographic and overview

You are invited: Open Forum Program

With a series of short live inspection demonstrations and talks from experienced industry professionals, our Olympus Open Forums will give you a rapid understanding of how Non-Destructive Testing and Remote Visual Inspection are used and benefit the Aviation Industry.

NDT topics

- Rapid Inspection of Composite panels using Phased Array Ultrasound: The new RollerFORM XL scanner

- Phased Array Ultrasonic Testing for shallow cracks in fuselage

- Bond Testing

- Eddy Current Array (ECA)

Speakers: Mickael Barbeyrol and Florin Turcu

RVI topics

- Precision Measurement - 3D Stereo

- Image enhancement during BSI

- Inspection Management with the IPLEX

- Measuring defects with confidence

Speaker: Hafees Fraisada

Solutions at Our Booth

Borescope Solutions for Efficient Aircraft Engine Inspection

Assessing the internal environment of jet engines to detect cracks, erosion, and other flaws is crucial for effective maintenance. IPLEX™ videoscopes provide maximum probability of detection for critical defects in jet engines – delivering reliable inspection results that ensure optimal aircraft performance and safety.

The advanced features of IPLEX™ series portable videoscopes include:

- High-resolution images and stereo measurement that enable accurate identification and measurement of cracks

- Ultra-bright illumination, which increases the probability of detection (POD) for rapid and easy identification of defects

- Excellent maneuverability for rapid navigation of the videoscope to the inspection location

- Super wide-field stereo that measures flaws from a greater distance, ensuring all potential defects are captured

- The dedicated Working Channel Scope and retrieval tools provide a versatile solution for removal of foreign object debris (FOD) and hook inspection

If you have any questions about the advanced features of IPLEX™ videoscopes, visit our booth at MRO Europe, where our team will be happy to discuss your individual inspection requirements.

Additional content

If you would like to learn more about how IPLEX™ videoscopes can streamline your inspection processes, check out the links below:

Blog: 3 Reasons to Add a Working Channel Scope to Your RVI Toolbox

Blog: How to Confirm Videoscope Measurement Points with Confidence

App note: Visual Inspections of Commercial Jet Engines

Related Products & Services

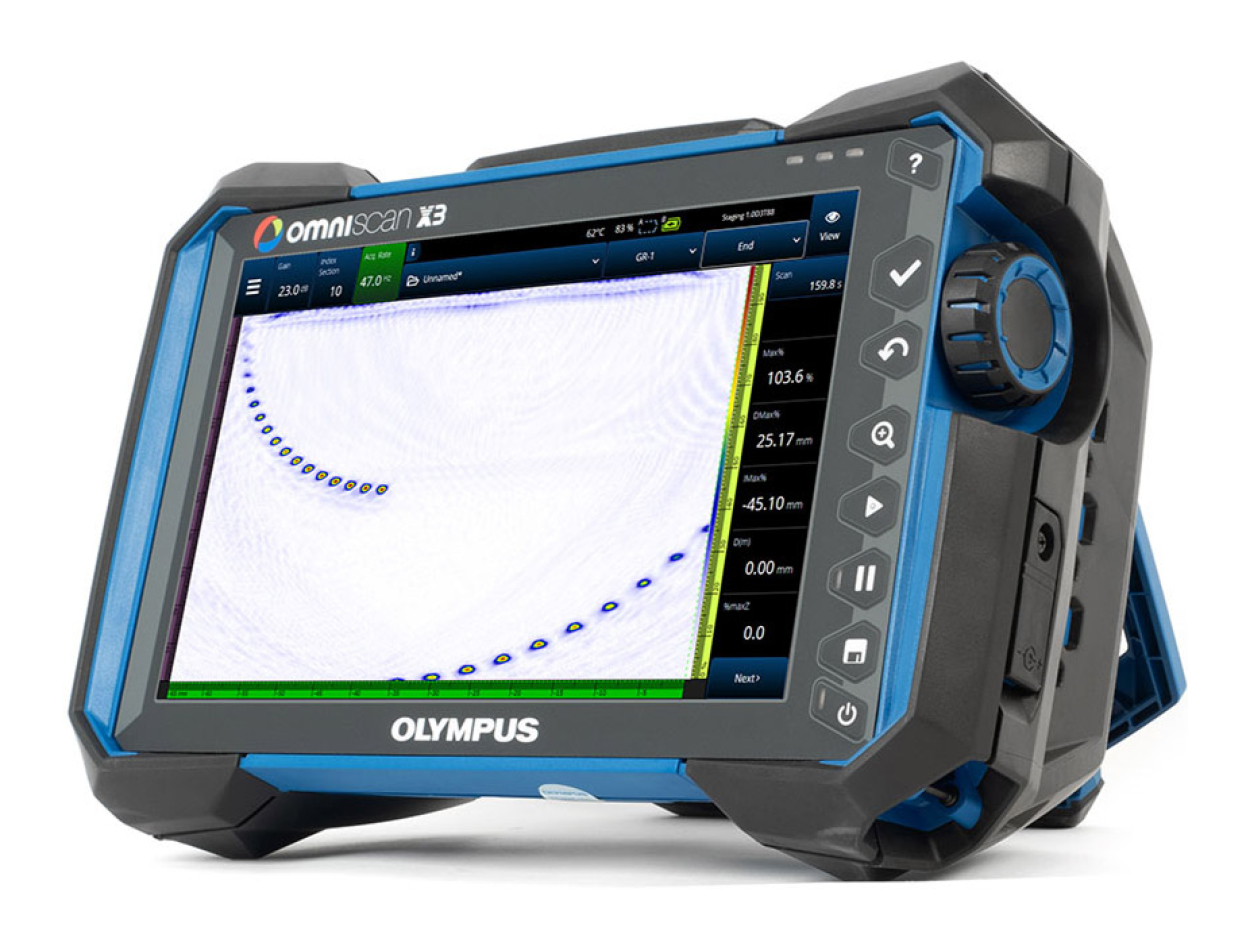

NDT Flaw Detectors–Complete Solutions for Reliable Aircraft Inspection

Olympus NDT solutions deliver the latest in inspection technology for the aviation industry. Our extensive portfolio of flaw detectors, thickness gauges, transducers, probes and more, feature the software you need to meet global inspection requirements of the aviation industry.

Visit our booth to discover how these powerful tools allow you to complete even the most demanding inspections with confidence - and how phased array analysis enables faster detection of faying (back wall) surface cracks in aircraft fastener holes.

We’ll be displaying the latest and most advanced OmniScan X3 phased array flaw detector - already a trusted solution around the world for extending the life of aircraft.

- Precise data acquisition and visualization with reliable analysis of ultrasonic signals

- Fast calibration and intuitive user interfaces which streamline inspection setup and reduce time to completion

- Powerful imaging capability using the total focusing method (TFM) and full matrix capture (FMC) method which ensure acquisition of detailed images

- An effective solution for detection of defects such as scribe marks at fuselage joints

Additional content

To learn more about our range of advanced flaw detection equipment, take a look at our application note and related product pages:

Blog: Taking Flight with an NDT Level III—Aircraft Inspection Using Eddy Current Testing

Product page: Flaw Detectors / Phased Array Flaw Detectors

Video Gallery: RollerFORM Scanner – Phased Array Wheel Probe

Related Products & Services

Mobile Material Verification with the VANTA XRF portable analyzers

With rapid and accurate in-field and non-destructive testing of material composition, Vanta handheld XRF analyzers ensure expensive or mission-critical components and machinery have the correct alloy grades and material composition, regardless of the material source. The applications of Vanta handheld analyzers include:

- Incoming material verification

- Blade coating verification

- Confirmation of correct repair materials

- Wear metals and additives in oil and fuel

Visit our booth at MRO Europe, where you can chat with our team and find out how Vanta analyzers can help you overcome your application-specific inspection challenges

Additional content

Want to learn more about material verification using Olympus XRF technology? Then check out the links below:

Blog: How to Add a Coating Model on Your Vanta Analyzer

Blog: Fuel Oil Analysis Using Handheld XRF - An Experiment

App note: VDM Metals Exceeds Client Expectations with Vanta™ Handheld XRF

App note: Analyzing Wear Metals and Additives in Oil and Fuel Using the VCA Model Vanta Analyzer

Related Products & Services

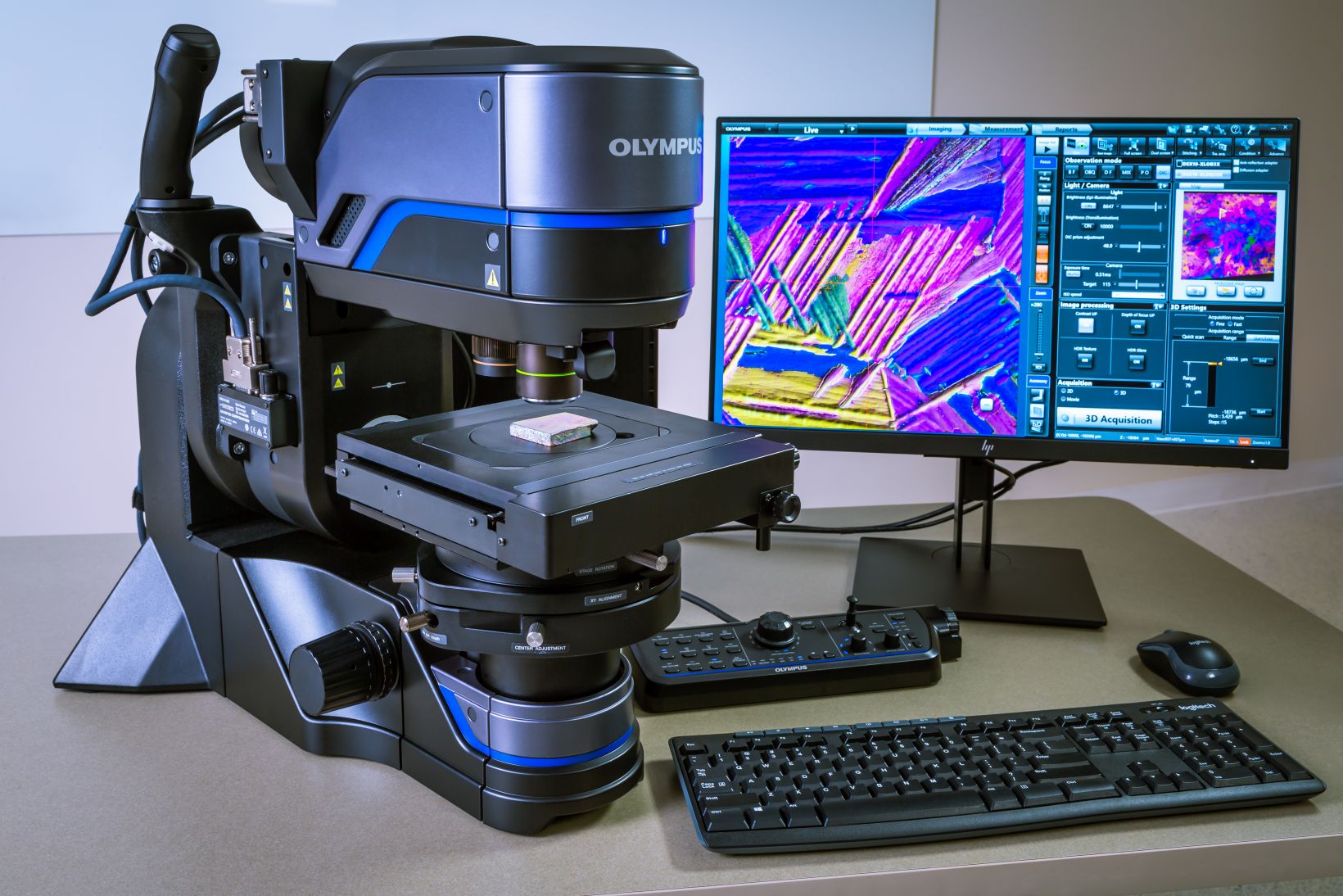

Failure Analysis and Composite Inspection for the Aviation Industry

Detailed inspection of larger composite structures and parts such as wing skin surfaces, floor beams or fuselage can be challenging with conventional microscopes. However, with the long working distance and high-resolution objectives provided by the DSX1000 digital microscope, identifying flaws such as delamination and assessing layer thickness is faster and more straightforward than ever.

To learn more about how Olympus microscopes streamline inspection and root cause analysis across the aerospace industry, visit our booth at MRO Europe. In addition to getting a close up look at our microscopes, you can also find out about a range of applications including:

- Accurate identification of wear debris and aircraft fluid contamination with the CIX100 cleanliness inspection system

- Precise rework of aircraft PCBs with the SZX10 stereo microscope

- Reliable composite, engine part and rivet inspection and failure analysis with the DSX1000 digital microscope

- Wear metals and additives in oil and fuel

Visit our booth at MRO Europe, where you can chat with our team and find out how Vanta analyzers can help you overcome your application-specific inspection challenges

Additional content

To learn more about how Olympus microscopes can enhance your inspections, check out these resources:

Blog: The Advantages of Using Polarized Light to Identify Wear Debris

Infographic: Weld Inspection Solutions

Infographic: Measurement Solutions

Infographic: Composite Inspection Solutions

Resource Page: Olympus Solutions for Electronics Inspection