This single system supports both phased array and conventional UT technology and it performs immersion tank testing and manual inspection.

Owing to the complete customer support provided by Olympus, the capacity for customization and the wide range of products it can inspect, this system is sure to meet your needs.

The immersion tank testing system for ultrasonic inspection developed by Olympus is an automatic scanning system that analyzes and evaluates the volume of the inspected part and the weld joint with high accuracy and speed. Customizable analysis software generates an image of the acquired data, automatically calculates and evaluates the defect area, processes 3D imaging, displays defect distribution, and assigns a pass/fail grade.

Features of the Olympus Immersion Tank Testing System

Comprehensive support from a world leader in phased array technology

Because of its extensive experience with phased array systems and portable instruments, Olympus is capable of ensuring that your application and inspection needs are met and that you receive the necessary training.

The immersion tank testing/manual inspection system features both phased array and conventional UT testing, improving the performance rate.

Inspection is not limited to the immersion tank with this system because the phased array flaw detector can be removed and it is portable, which gives you the flexibility to inspect very large sized objects and materials of various shapes. You can also use it with a variety of scanners, probes, and software. You can also choose between conventional UT and phased array according to your situation. Because of the versatility offered by this one system, it can improve operating rates and performance, and it is cost effective.

You can configure and customize your system according to your needs—from low cost to high-end.

Depending on your needs, Olympus recommends which UT flaw detection hardware features and software customization to select from the broad range of choices available, such as one-button operation. The Immersion Tank Testing System can be integrated into your current facility to update and reconfigure old scanners and phased array systems.

Reduces inspection time though the use of phased array technology

Conventional UT Inspection/Phased Array Inspection

Phased array instruments can scan a 200 x 200 mm area, at 0.5 mm resolution and 50 mm/s inspection rate, in less than 1 minute with one line wide scan. Conventional UT instruments would take approximately 25 minutes to inspect the same area.

Application Example

- Disbond and void testing for composites (including CFRP) and anode materials

- Automotive industry part research and development, such as aluminum ingots, prototype testing, manufacturing inspection, inline quality inspection, etc.

System Overview

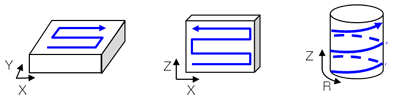

scanner for bent plate

scanner for pipe

phased array probes

Examples of customization capabilities:

- Scanning patterns can correspond to the part (for example, the standard X-Y axis scan → Y-X axis scan).1

- The analysis software can be customized.2

- The system’s size can be changed to suit the constraints of the installation location.

- Phased array probes can also be customized.

- Configurable for in-line inspection

- Retrofit capability for conventional equipment (example: reconfiguration of an old scanner and a phased array system)

1 According to the geometry of the sample, the scanning pattern can accommodate an X-Y scan, an X-Z scan and a Z-R scan.

2 We provide a data analysis that fits your needs, incorporating various external analysis software for your inspection application.

System Example

Specification example

| Inspection method | Conventional UT | Phased array | ||||

| Flaw detector |

Pulser/Receiver

Waveform processing software (oscilloscope) | Omniscan SX UT |

Omniscan SX PA

(16/64) |

Omniscan MX2 PA

(16/128、32/128) |

Omniscan MX2 PA

(16/128、32/128) TomoView analysis software |

Omniscan MX2 PA

(16/128、32/128) Analysis software (extended) |

|

UT

Frequency | 0.5–75 MHz | 0.5–20 MHz | 0.5–15 MHz | |||

| Features |

High frequency inspection

|

Simple and low-cost entry model

|

High speed inspection with phased array

|

High speed inspection with phased array

|

High speed inspection with phased array

|

High speed inspection with phased array

|

| Phased array OmniScan MX2 unit specification | ||||||

| Maximum aperture quantity | 16 or 32 | |||||

| Maximum aperture quantity working in parallel | 128 | |||||

| Frequency bandwidth | 0.5 - 20 MHz | |||||

| Inspection methods | Phased array or conventional UT | |||||

| Scanning range | X-Y axis from 200 mm | |||||

| Minimum scanning resolution | 0.1 mm | |||||

| Standard package specification* | |

| Data analysis by PC | Yes |

| Two-axis scanning | Yes |

| Data confirmation by a phased array unit | Yes |

| Remote control via PC | Yes |

*OmniScan MX2 (PA1664), immersion tank testing system, TV2.10 Full 5L64‐I1 probe

A high performance package is also available for the automatic analysis of defects in parts in an in-line system.

For details about an Immersion Tank Testing System, please contact here.

| Two-axis immersion tank testing system: Standard instrument specification | |

| Drive system | Motor-drive control method |

| Scanning speed | Max 300 mm/s |

| Frequency bandwidth |

0.5–20 MHz (phased array)

0.5–35 MHz(UT) |

| Inspection methods | Phased array or conventional UT |

| Inspection range |

X-Y axis from 200 mm

Z axis from 100 mm |

| Minimum resolution of inspection pitch | 0.1 mm |

**The Immersion Tank Testing System is only available in Japan.