Overview

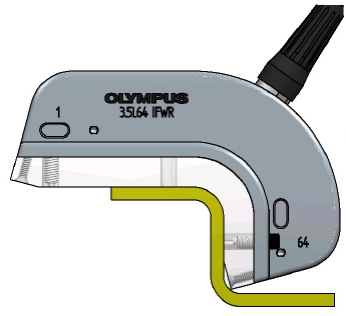

Olympus manufactures custom immersion flat with radius (IFWR) phased array probes to increase coverage, improve detectability, and simplify data analysis. Mistras Group Inc. has increased productivity by using a single custom Olympus 3.5MHz 64 element IFWR probe; replacing two probes in their composite inspection setup. Mistras Group Inc. provided the following details and graphics outlining their success.

Old Technique

Mistras previously used 1 linear 64 element, 1 concave 32 element probe, and the OmniScan MX to inspect 8 zones across a composite part. The inspection with two probes took approximately 2.5 hours.

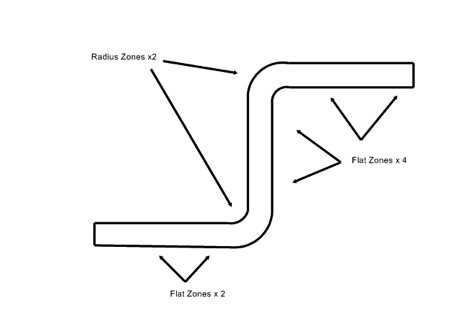

Figure 1: 8 zones to cover the entire composite piece

|  |

Firgure 2: Two setups required to cover the entire part

The C-scan data recored from multiple probes and passes becomes more difficult to record and analyze. Each scan must be properly identified to ensure acurrate analysis. |

New Technique

Using the Olympus custom IFWR probe, inspection of all 8 zones can be completed with one probe in two passes; reducinig inspection time by approximately 50%. |  Figure 4: Custom Immersion Flat With Radius (IFWR) probe setup |

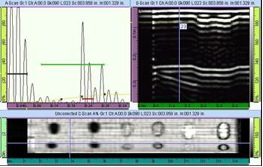

Reducing quantity of probes while increasing coverage has proven to simplify recording and analyzing data. Each part now has only two C-scan’s to analyze. |  Figure 5: Data captured from one pass covers 4 zones |

Conclusion

Olympus has worked with Mistras Group Inc. to provide a custom probe which has proven to reduce inspection time, improve detectability, and simplify data analysis. Olympus has the capability to manufacture IFWR probes to customer specifications and specific part requirements.

To inquire for custom probe possibilities specific to your application please contact SCE.PM@olympusndt.com or submit details via our online custom probe form.