Surface mining often entails the use of large trucks and shovels including massive Dragline excavators in large scale operations to remove overburden to access coal and other deposits of desired resources. Due to the size of this equipment many of the components are very thick resulting in challenging applications for ultrasound. In addition the preferred test methods are with the components in place and in operation which can mean limited access to the areas that need inspected. Phased Array can offer many benefits to these inspections. There are many lug and bore type components utilized to hold various shafts and pins that allow equipment operation.

Lug and Bore Inspections

Lug and bore inspections typically can be very thick wall (7-12” +). A typical high stress area prone to cracking is the inner bore. It is preferred to inspect these components with the pin or shaft in place to allow continued operation of the piece of equipment. For conventional shear wave ultrasonics this poses a limited access issue and often multiple wedges must be changed to inspect as much of the inner bore as possible.

Typical Lug in Place in Dragline Excavator

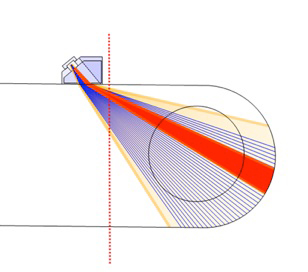

Typical Coverage from Conventional Ultrasonics and Phased Array. Red line shows possible limited access

Phased Array Benefits

- Multiple angles allow for single probe and large coverage area in lug bore

- Better detection of "winding crack"

- Better coverage when in position with limited access

- Imaging and data recording for crack monitoring

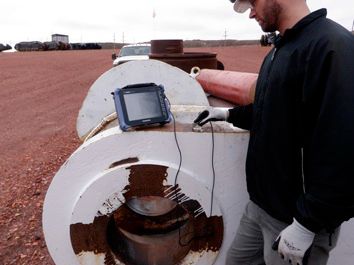

Typical Lug for Bore inspection utilizing OmniScan SX. This component has the boom of a dragline excavator.

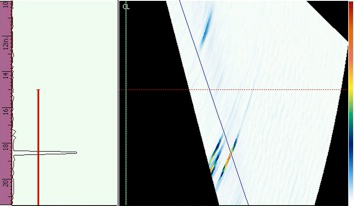

Phased Array allows simultaneous viewing of bore geometry and cracks propagating from the inner surface.

Equipment Used

OmniScan SX or MX2

- Portable for easy access inside cramped area of excavator

- Conventional, Phased Array and TOFD capable

- Manual or encoded data

Phased Array Probes and Wedges

- Vary on application

- 2.25 MHz common frequency

- Shear and 0 degree wedges

- Contact wear faces for long 0 degree metal paths

Optional Software and Accessories

- OmniPC post analysis software

- Small Mini-Wheel Encoder