What Is a Phased Array Transducer?

A phased array transducer is an ultrasonic testing transducer that contains a series of elements that can be pulsed in unison to direct sound waves in a specific direction. This makes it possible to test multiple inspection zones in a single instance.

What is an Array?

An array is an organized arrangement of large quantities of an object. The simplest form of an ultrasonic array for NDT is a series of several single element transducers arranged to increase inspection coverage and/or the speed of an inspection.

Phased Array Transducer Uses

Phased array transducers are used for various NDT inspections, including:

- Tube inspection, where multiple probes are often used to detect cracks, find laminar flaws, and measure overall thickness

- Forged metal parts, which often require multiple probes focused at different depths to detect small defects in a zonal manner

- A linear arrangement of probes along a surface to increase detection of laminar flaws in composites or corrosion in metals

These inspections require high-speed, multi-channel ultrasonic equipment with proper pulsers, receivers, and gate logic to process each channel, as well as careful fixturing of each transducer to properly set up the inspection zones.

In its simplest form, a phased array probe is a series of individual elements in one package. While the elements are much smaller than conventional transducers, these elements can be pulsed as a group to generate directionally controllable wavefronts. This electronic beam forming enables multiple inspection zones to be programmed and analyzed at high rates of speed from a single position transducer. This is discussed in greater detail later in this tutorial.

Phased Array Transducer Characteristics

Phased array transducers are functionally categorized according to the following basic parameters

Type: Most phased array transducers are the angle beam type, designed to be used with a plastic wedge, straight plastic shoe (zero-degree wedge), or delay line. Direct contact and immersion transducers are also available.

Frequency: Most ultrasonic flaw detection is done at frequencies between 2 MHz and 10 MHz, so most phased array transducers fall within that range. Lower and higher frequency probes are also available. As with conventional transducers, penetration increases with lower frequency, while resolution and focal sharpness increase with higher frequency.

Number of elements: Phased array transducers commonly have 16 to 128 elements, and some have as many as 256. A larger number of elements increases focusing and steering capability, and it can increase area coverage as well. However, more elements increase both probe and instrumentation costs. Each of these elements is individually pulsed to create the wavefront of interest. As a result, the dimension across these elements is often referred to as the active or steering direction

Size of elements: As element width gets smaller, beam steering capability increases. However, large area coverage will require more elements at a higher cost.

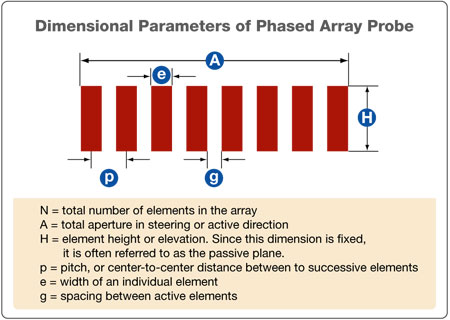

The dimensional parameters of a phased array are customarily defined as follows:

The dimensional parameters of a phased array probe are usually defined as:

- N = the total number of elements in the array

- A = total aperture in steering or active direction

- H = element height or elevation; since this dimension is fixed, it is often referred to as the passive plane

- p = pitch, or center-to-center distance between two successive elements

- e = width of an individual element

- g = spacing between active elements

This information is used by instrument software to generate the desired beam shape. If it is not entered automatically by probe recognition software, then it must be entered by the user during setup.

Inside a Phased Array Transducer

Phased array transducers come in a wide range of sizes, shapes, frequencies, and number of elements, but they all contain a piezoelectric element that has been divided into a number of segments.

Contemporary phased array transducers for industrial NDT applications are typically constructed around piezocomposite materials, which are made up of many tiny, thin rods of piezoelectric ceramic embedded in a polymer matrix. While they can be more challenging to manufacture, composite transducers typically offer a 10 to 30 dB sensitivity advantage over piezoceramic transducers of an otherwise similar design. Segmented metal plating is used to divide the composite strip into a number of electrically separate elements that can be pulsed individually. This segmented element is then incorporated into a transducer assembly that includes a protective matching layer, a backing, cable connections, and an overall housing.

Types of Phased Array Transducer Configurations

The animation above depicts a linear array with a rectangular footprint. This is a common configuration for a phased array. Arrays can be arranged as a matrix for more beam control over a surface cross section or as circular arrays for a more spherical focusing pattern.

Phased array transducers can be arranged into several different configurations, each with distinct advantages and disadvantages. Common phased array transducer configurations include:

Linear Phased Array Transducer

Linear phased array transducers have elements arranged in a straight line and are the most common configuration in phased array ultrasonic testing. Linear phased array transducers are easy to make, but they need to be large for deep focusing.

Annular Phased Array Transducer

Annular phased array transducers and segmented annular phased array transducers feature elements arranged in circular rings with a common center. These transducers can provide elliptical and spherical beams with steering capabilities at different depths. However, their complex design makes manufacturing them challenging.

Convex Phased Array Transducer

Convex phased array transducers, also called curved or curvilinear phased array transducers, have elements arranged in an arched line. These transducers are good for in-depth testing, but image resolution can decrease as the depth increases.

Square Phased Array Transducer

Square phased array transducers have their elements arranged in a square pattern. While this pattern provides excellent steering capabilities, the complex design makes manufacturing square phased array transducers difficult.

Circular Phased Array Transducer

Circular phased array transducers feature elements arranged in a circular ring but without a common center. They provide excellent steering capability at varying depths, especially in curved targets. However, their complex design makes manufacturing circular phased array transducers difficult.