奥林巴斯DELTA手持式X射线荧光(XRF)分析仪将具有特高分辨率的硅漂移探测器(SDD)与强大的4W X射线管结合在一起使用,可以非常迅速、精确地完成XRF分析。与奥林巴斯传统的Si-PiN二极管X射线探测器相比,硅漂移探测器(SDD)具有三大主要优势:1)在给定时间内可以探测和处理10倍以上的X射线;2)可以提供更好的能量分辨率;3)可以提供更好的峰值与背景辐射量的比率。由此可以得出结论:硅漂移探测器在采矿和勘探应用中可以获得好得多的精确度以及更低的检出限。 在分析铁矿石以及相关的痕量元素时表现出优越的高性能:铁矿石精矿的最佳进料品位以重量算通常是铁高于60 %,磷低于0.20 %,二氧化硅在3 %到7 %之间,铝低于5 %,而且硫和钛的百分比都很低。 |  |

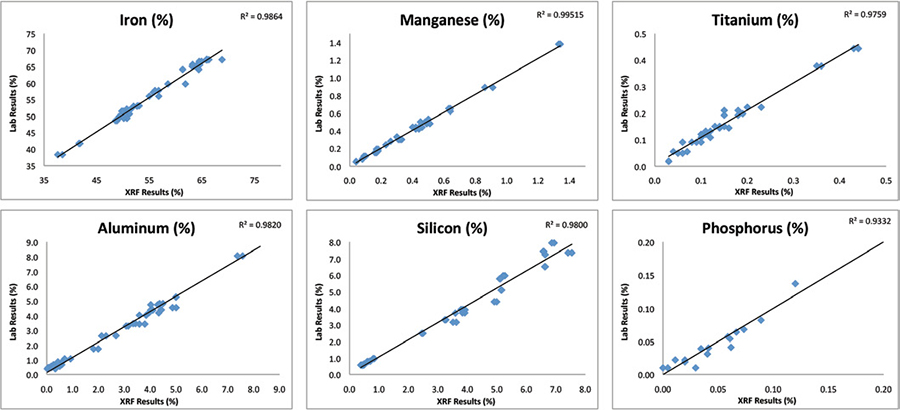

如果进料中含有某些痕量元素,即使含量很少,也可能会对高炉中铁矿石的熔炼情况产生重大的正面或负面的影响。应用了硅漂移探测器(SDD)技术的DELTA分析仪,如今可以确定铁矿石的所有重要的晶相。对于含铁量在较宽(30%到80%)范围内的铁矿石进行分析时,可以准准地判断铁元素的含量。可以准确地分析锰(Mn)、钛(Ti)、铝(Al)、硅(Si)、磷(P)、硫(S)元素,以及其他25种元素。

探测典型的富含赤铁的条纹状铁矿石中铁、锰、钛、铝、硅和磷元素的性能。(使用一个装配有硅漂移探测器的DELTA分析仪在空气中进行90秒的检测)

轻元素的分析和样本的制备

在野外使用便携式X射线荧光分析仪进行分析时,轻元素(LE)一般被认为是原子数(Z)少于18(氩)的元素,而且通常是指包含镁、铝、硅、磷、硫和氯的元素组。对铝土矿床的调查主要是勘探到这组轻元素,特别是铝、硅加上钙和钾元素的组合,而且矿化类型通常发生在粗晶基质中。因此,如果样本的非均质性较高,则会极大地影响对这些元素的分析,为了获得有意义的(达到可使用户做出决定的水平)分析质量,可能需要进行某种形式的样本制备工作。样本制备包括将样本碾碎为粗粒,如果需要,还要将样本碾碎成约为200 μm的粉末,然后将样本放入到一个使用聚丙烯薄膜的XRF样本杯中(不要使用聚酯薄膜,因为不能通过聚酯薄膜分析轻元素)。

为什么要使用野外便携式XRF分析仪?

新一代XRF分析仪的“真正便携性”特点基本上实现了将“微型实验室”搬移到野外进行分析的愿望,当然这种实践还存在着明显的局限性。奥林巴斯清楚地了解这些局限性,也不避讳讲明这些局限性:(1)检出限比基于实验室的分析技术更高;(2)精确度比基于实验室的分析技术更低(较高的误差值,但是不影响检出限以上的准确度);(3)结果的重复性较低。

野外便携式XRF分析仪不应被看作一种可替代实验室的仪器,而应该与实验室结合起来使用,而且同时要遵守行业标准报告协议,如:在ASX(JORC规范)和TSX(43-101)中确定的协议。野外便携式XRF分析仪的主要优势在于其可以快速、实时、动态地生成可在空间注册的地球化学数据集的能力。

现在地球学家可以在野外、受关注样本的采集现场,即时、动态地推测出所观察风化层或岩石层的元素特性,并根据详实的信息做出明智的决定。地质工作者如今可以使用即时、互动的方式完成勘察项目的管理,目标的设定,以及相关的矿化定向工作。这种方式由于减少了时间密集型重复性工作而极大地缩短了完成项目的时间进程,例如:无需挖掘样本并将样本送到实验室,可以省去因此而产生的“正常”耗时的周转时间和滞后时间。野外便携式XRF分析仪可被看作一种预筛选工具,用于选择更合适的、质量上乘的样本,然后地质人员可以将这些样本送入实验室,进行更全面、更详细的分析。

此外,可在野外实时完善采样项目的能力, 意味着地质人员可以即时轻松地增加样本的密度和分辨率。

这些在野外工作效率方面获得的优势推进了完成项目的时间进程,有助于相关公司更好地利用野外的工作时间,并可在很大程度上节省勘探预算经费。

检出限:牵涉着百万美元的问题

分析检出限(LOD)的确定并不直接与所选择的仪器相关,而是取决于很多方面。影响检出限的某些因素如下(括号中为影响因素的类别):

|  |

“因此可以说,在使用野外便携式XRF分析仪确定元素检出限的工作中,样本是最具影响力的因素。”