- Home

- Microscope Solutions for Materialography

- Non-Metallic Inclusion Solutions

Nonmetallic inclusions (NMI) are compound materials embedded inside steel during the manufacturing process. Inclusions have a different chemical origin and give different mechanical properties to steel, such as formability, toughness, machinability, and corrosion resistance. As a general rule, the fewer or less severe the inclusions, the higher the quality of the steel. Therefore, analyzing and documenting nonmetallic inclusions is important for quality control.

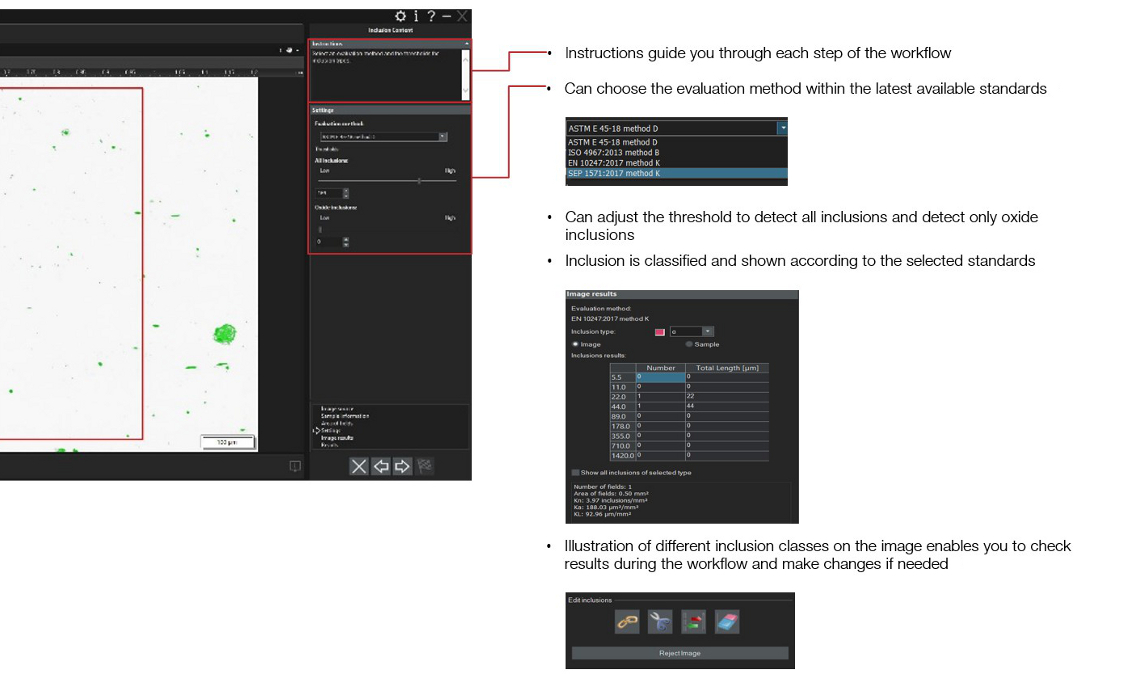

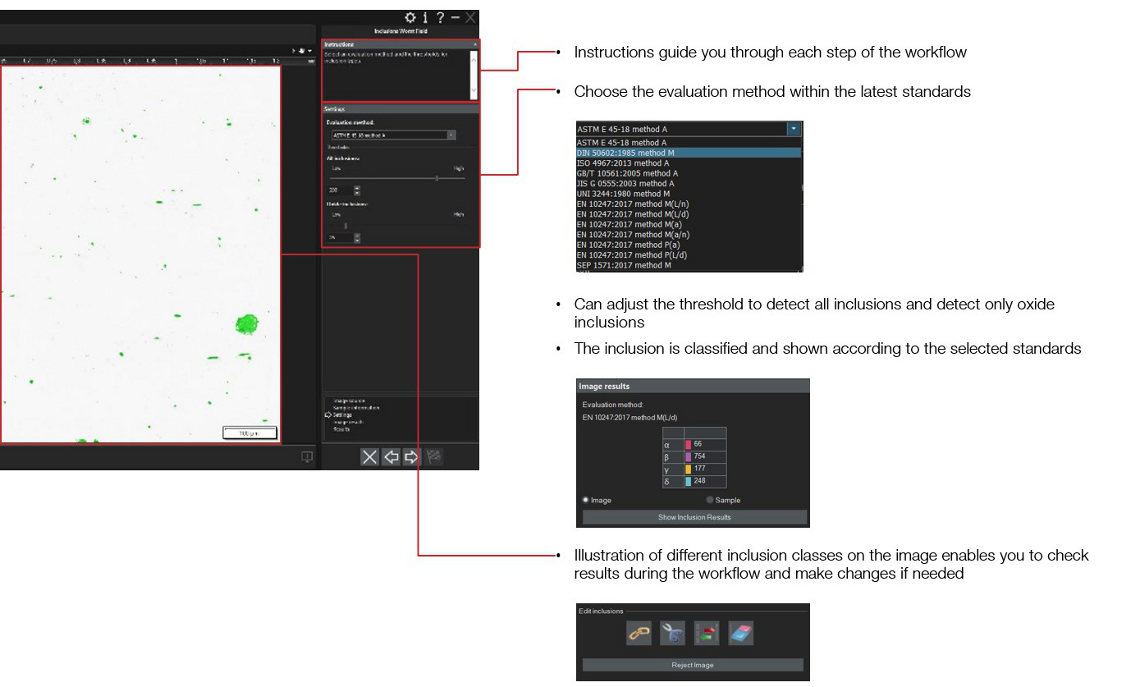

Our image analysis software offers a guided workflow solution for nonmetallic inclusion rating in steel. This solution includes two different rating methods: Worst Field and Average Content.

NMI Analysis Using the Worst Field/Largest Inclusion Method

Results:

|  |

NMI Analysis Using the Average Content Method

A significant area (usually 160 mm²) or number of fields (usually 320) must be scanned. In addition, the count of fields (inclusions) of each class must be determined (method D of ASTM). The weighted sum, which is equivalent to the area fraction (method K of DIN, UNI and EN, method B of ISO, NF, and GB), can be built to interpret the average content. |  |