A major eddy current application around the world uses rotating scanner probes for the inspection of fastener and bolt holes. In these inspections, a handheld rotating bolthole scanner is the tool of choice. However, many applications require manual scanning using bolthole and threaded probes. With updated hardware, this manual inspection has been improved for both the inspector and the longevity of the equipment.

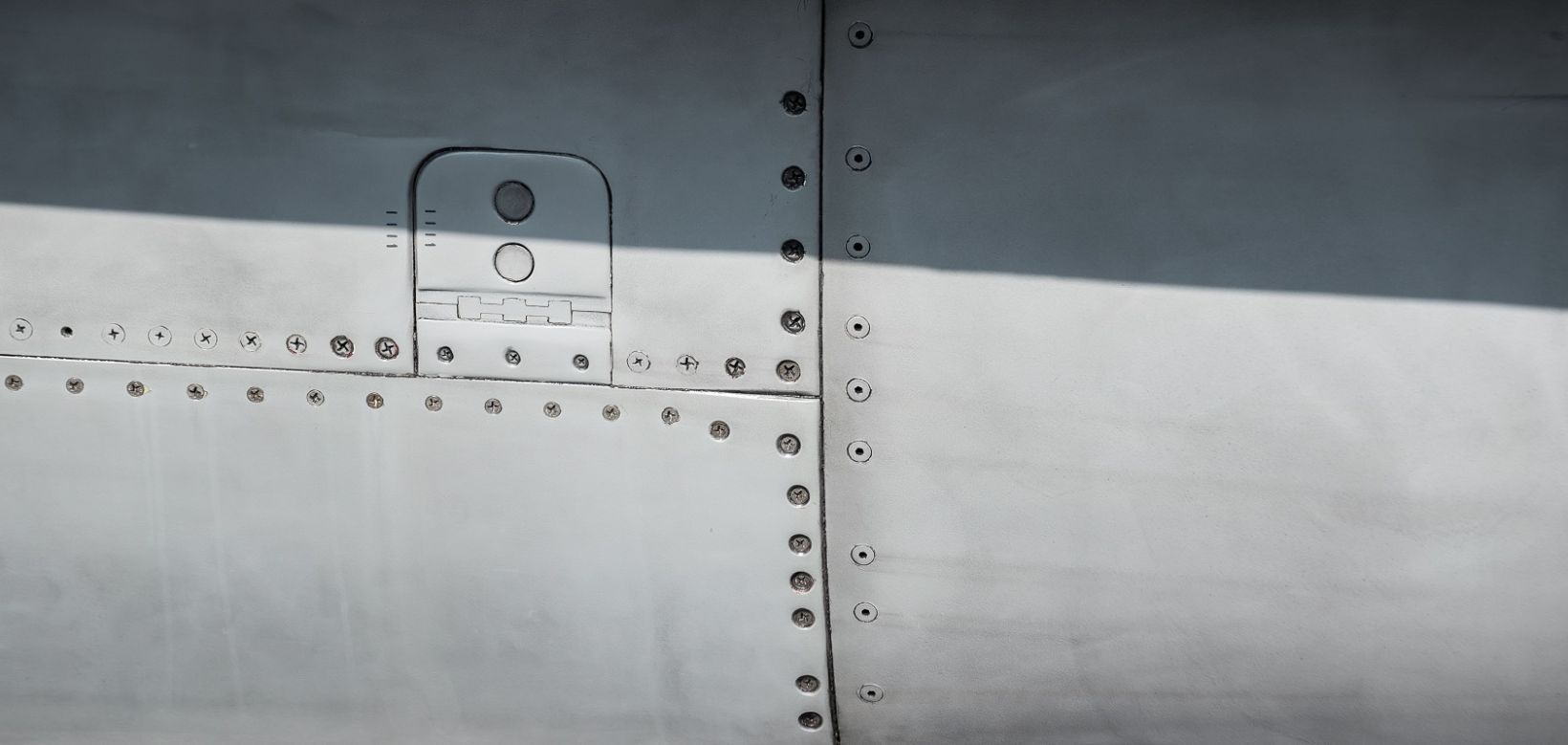

Figure 1. Inspection of fastener holes on an aircraft using a MiniMite™ rotating bolthole scanner and NORTEC™ series eddy current flaw detector.

The Challenges of Manually Inspecting Fastener and Bolt Holes

Consider the example of an aerospace fastener hole inspection for the detection of interior diameter (ID) cracks in all orientiations. When using a typical manual bolthole or threaded probe, the cable must spin alongside the probe for testing to occur. If multiple rotations are required for inspection, this can cause unwanted cable bind. A twisted cable can make the inspection cumbersome and place unneeded stress on the cable, leading to equipment failure.

Figure 2. Manual bolthole probe.

Eliminating Cable Bind in Manual Inspection of Fastener and Bolt Holes

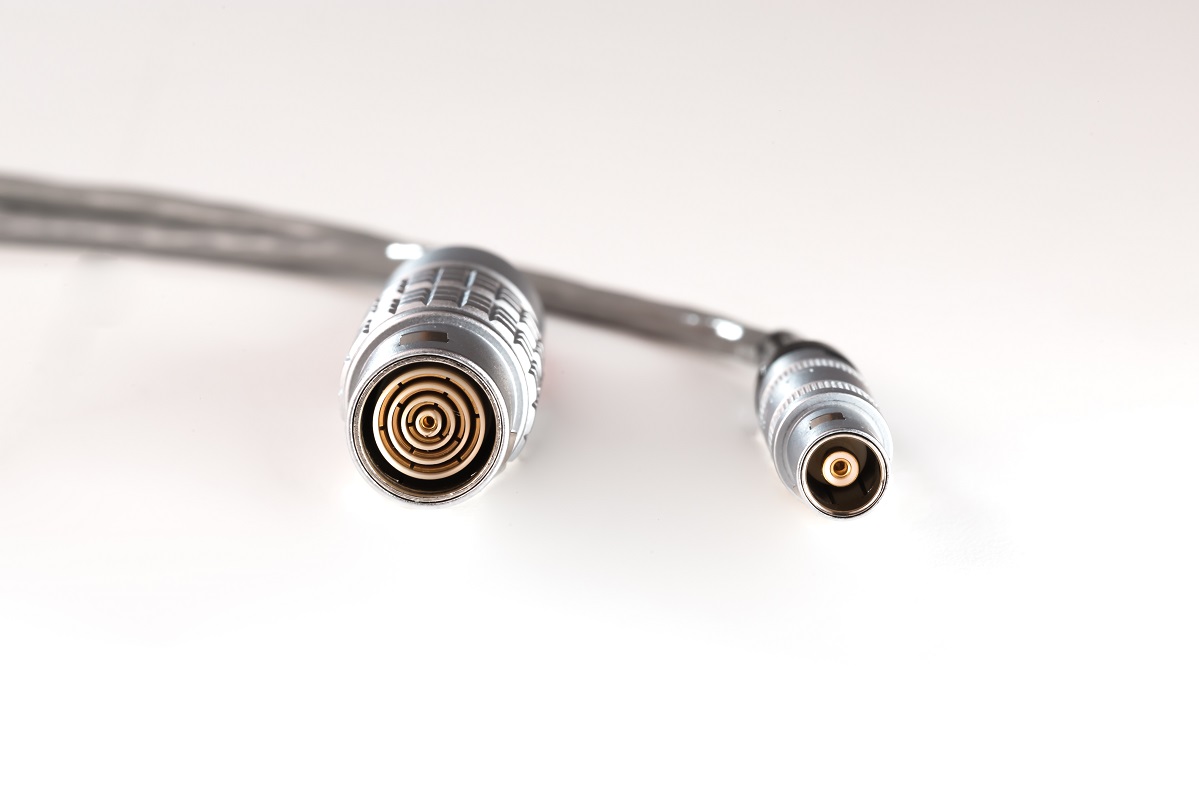

Evident has incorporated a special-purpose concentric LEMO connector option that allows for a free-spinning probe, eliminating cable bind.

Figure 3. LEMO concentric contact connectors.

The solution requires inspectors to spin only the probe, rather than both the probe and cable assembly. Along with improved ease of use, the cable offers exceptional performance with minimal to no electrical noise.

Figure 4. Standard manual probe and cable, showing typical cable bind when testing fastener or bolt holes manually.

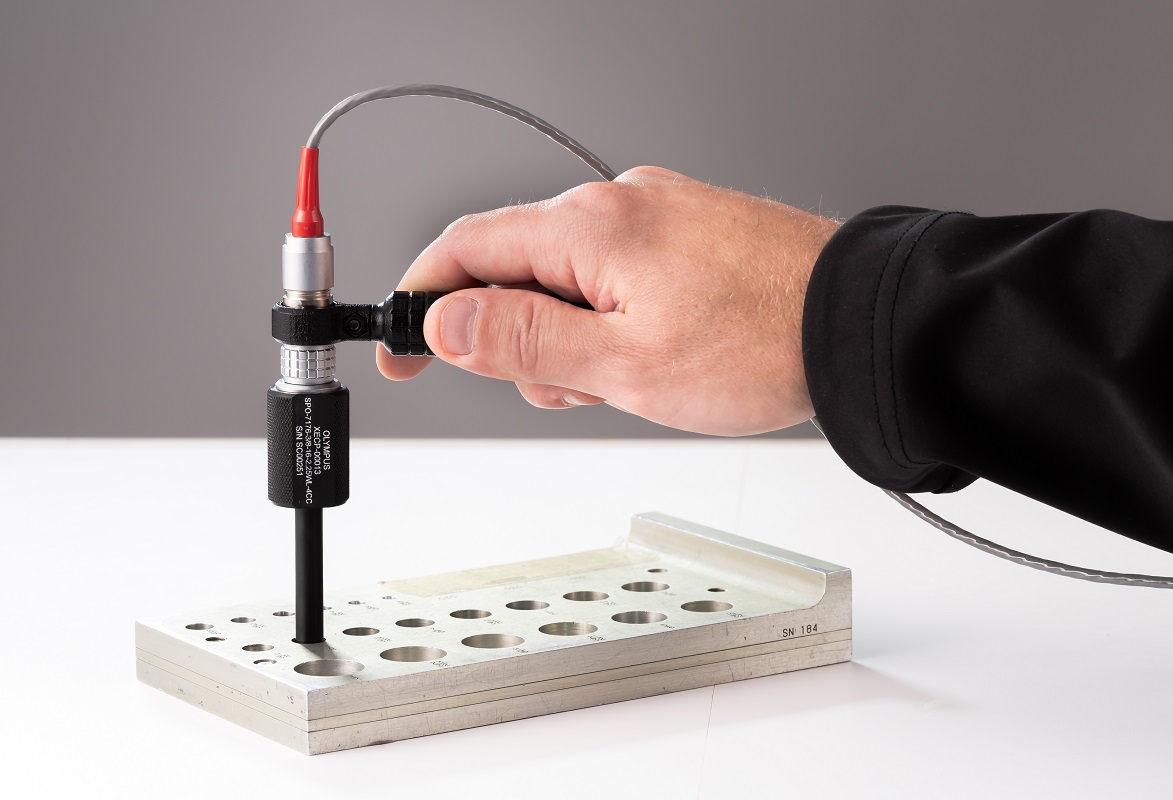

Figure 5. Free-spinning concentric connector with handle that eliminates unwanted cable bind in manual scanning of fastener and bolt holes.

The updated cable and connector hardware makes manual rotation tests, such as bolthole or threaded hole applications, easier and more comfortable for the operator. At the same time, it reduces strain on the equipment and maintains a clean signal-to-noise ratio.

How to Order Concentric-Connector Bolthole and Threaded Probes

All requests for custom concentric-connector bolthole and threaded probes from Evident are reviewed through our engineer-to-order (ETO) process and can then be quoted along with cable 10-039146-00 [Q8000339]. To learn more, contact your local sales representative or reach out to us online.