碳钢平板和管道的超声检测 - NDT

概述

碳钢

碳钢

管道和平板

奥林巴斯用途广泛的焊缝检测解决方案采用多种技术对平板和外径等于或大于4.5英寸的管道进行多产高效的检测。相控阵、衍射时差以及常规超声等技术在检测过程中可被单独使用,也可以组合在一起使用,以覆盖整个焊缝,并获得很高的检出率。

这种解决方案还可以使用不同的扫查方式,获得缺陷定位和定量的准确数据。扫查器具有优质的稳定性和编码性能,不仅可使检测符合规范的要求,还可获得质量更好的检测数据。在以手动、手动编码、半自动或自动方式进行扫查并收集数据时,需使用不同的扫查器。

奥林巴斯的碳钢焊缝检测解决方案将奥林巴斯的采集设备、扫查器、探头,以及根据用户的需要量身定做的软件结合在一起使用。这种解决方案可以进行缺陷的长度和深度定量,以根据规范做出接收/拒绝的判断。

复合式扫查

|

奥林巴斯的NDT SetupBuilder更新版软件提供了进行复合式声束扫查的性能。这项创新型检测策略将扇形声束和线性声束混合在一起,进行检测,具有很多优势特性,例如:

|

焊缝系列PA探头和楔块

| A31和A32相控阵探头和楔块具有独特性能,可使检测达到更高的水平。

|

高温检测

| 如果用户要求,我们可以提供一种与新款A31和A32相控阵探头和奥林巴斯的Mini-Wheel(袖珍轮)编码器相兼容的高温楔块选项。这种可选楔块有助于对表面温度高达150 ⁰C的工件进行检测。 |

次轴聚焦(PAF)楔块

| 已获得专利权的奥林巴斯次轴聚焦楔块系列产品有助于补偿次轴方向上的声束扩散问题,从而可以有效地进行管道环焊缝的检测。较小的声束宽度可以在扫查轴方向上定量较短的缺陷,从而有助于降低废品率。此外,由于声束能量的聚焦改进了信噪比(SNR),从而使缺陷图像更加清晰。 |

一般技术

Ultrasonic Weld Inspection Solutions

The OmniScan flaw detector has an established track record for reliable and cost-effective phased array (PA) weld inspections as an alternative to radiography. Olympus ultrasonic weld inspection solutions provide an affordable means to inspect welds in compliance with major code and manufacturing requirements. An ideal combination of acquisition unit, scanner, encoder, and software, these solutions can be put to work virtually anywhere. Continuously improved and supported software makes the inspection of welds even easier, allowing you to complete your entire workflow more efficiently.

The Olympus weld inspection solutions applies to welds made of carbon steel or corrosion resistant alloy such as austenitic.

General Benefits:

- Fast weld inspection of different diameters, thickness, and materials

- 100% volumetric weld coverage

- Adaptable to butt welds, circumferential welds, long seams, one-sided access configuration, and most common weld profiles

- Portable for in-house and field inspections

Combining Different Techniques for Full Weld Coverage and Improved Efficiency

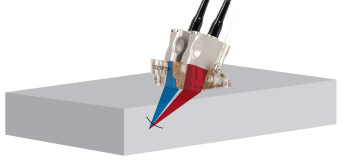

Phased Array Pulse-Echo Technique Phased array technique is based on the capacity to electronically modify ultrasonic beams generated by probes that contain multiple small elements. When these elements are excited using different time delays (focal laws), the beams are steered at different angles and focused at specific depths. |  |

Conventional UT Pulse-Echo Technique This technique uses a single element transducer to generate an acoustic beam at a fixed angle. The echo coming back to the transducer is interpreted by the instrument to provide information on size and position. |  |

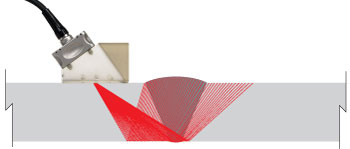

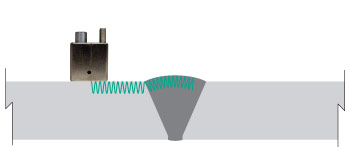

| Time-of-Flight Diffraction (TOFD) Technique Time-of-flight diffraction (TOFD) is an ultrasonic technique that relies on the property of defects such as cracks to diffract energy from their tips to the receiver probe when impinged by ultrasonic beams generated by the transmitter probe. TOFD technique uses a wide beam that provides good coverage and is independent of defect orientation. |  |

Transmit-Receive Longitudinal Wave (TRL) This technique uses separate transmit and receive probes to generate refracted longitudinal wave. The use of separate probes minimizes vulnerability to noisy material, which is especially beneficial for inspection of coarse grain alloy, such as austenitic and nickel. |  |

Surface Wave Technique The surface wave (creeping) technique is an ultrasonic test in which discontinuities are detected by the return of a creeping wave that tracks the surface of the component being tested. |  |

Ultrasonic Testing (AUT) in Lieu of Radiography Testing (RT)

Ultrasonic testing in lieu of radiography has proven very effective for pressure vessels, tanks, piping, and other weld configurations. Olympus ultrasonic weld inspection solutions features comply with ASME, API and other radiography replacement code requirements such as full raw data collection and the use of an encoder. Compared to conventional radiography, Olympus ultrasonic weld inspection solutions offer multiple benefits such as:

- No radiation safety hazards

- Eliminates work area disruption

- Real time digital archiving of inspection data

- Elimination of film archiving

- Improved productivity

- Improved probability of detection (POD)

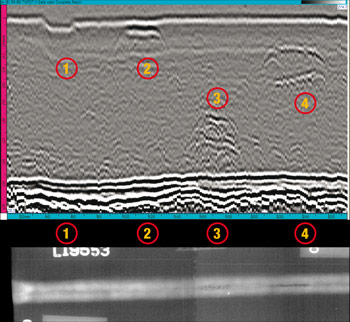

Comparing the Indications

|

|

Measurement Capabilities

| ID | Type of Defect | Ultrasound (AUT) | Radiography (RT) |

| 1 | Toe crack |

• Position X, Y, and Z

• Length sizing • Height sizing |

• Position X and Y

• Length sizing |

| 2 | Centerline crack |

• Position X, Y, and Z

• Length sizing • Height sizing | • No detection |

| 3 | Porosity |

• Position X, Y, and Z

• Length sizing |

• Position X and Y

• Length sizing |

| 4 | Incomplete root penetration |

• Position X, Y, and Z

• Length sizing • Height sizing |

• Position X and Y

• Length sizing |

Benefits of the Olympus Ultrasonic Weld Inspection Solutions

| Olympus Ultrasonic Solutions | Radiography (RT) | |

| Absence of Radiation hazard | Yes | No |

| Absence of restricted area | Yes | No |

| Ease of deployment on site | Yes | No |

|

Probability of detection (POD)

(Planar defects such as crack and lack of fusion) | Very good | Poor |

| Inspection throughput | Very good | Good |

| Depth sizing capability | High accuracy | Poor |

| Length sizing capability | High accuracy |

Good accuracy

|

扫查方式

扫查方式

我们的碳钢焊缝解决方案可与不同的扫查选项一起使用。

自动

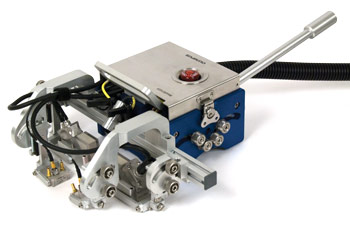

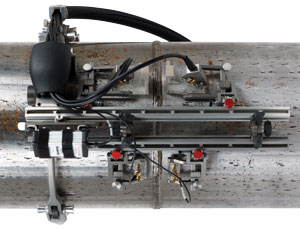

使用一对PA探头和最多三对TOFD探头的WeldROVER扫查器是完成碳钢焊缝检测的一种理想的自动扫查选项。它可使探头进行更快更平稳的运动,从而可更迅速地完成更准确的数据采集。 | 电动SteerROVER扫查器可让您远距离操控扫查器,对难以触及区域的碳钢焊缝进行高效自动扫查。使用具有坚固耐用触摸屏手持控制器的SteerROVER扫查器对环焊缝和纵向焊缝进行可靠的相控阵(PA)超声测试。可选RECON摄像头套件可帮助操纵扫查器、保持焊缝充分居中并有助于确保探头与表面保持接触。 |

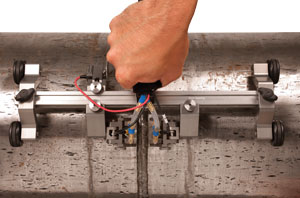

手动和手动编码

使用连接了Mini-Wheel编码器的编码PA探头,或VersaMOUSE手动扫查器,可通过手动方式对焊缝进行扫查。 |

半自动

|

| ||

|

| ||

|

技术相控阵技术可通过电子方式生成多个声束角度、声束类型和声束偏移。这样就可以方便地检测不同类型的焊缝,从而增强了检测的灵活性。 在需要进行高速扫查时,或在节省成本比提高灵活性更重要时,可以使用常规UT技术替代相控阵技术。 TOFD技术可以单独使用,进行快速简单的检测,也可以作为脉冲回波的一种补充技术使用。 在大多数碳钢焊缝检测应用中,将相控阵与TOFD技术结合起来使用,可以获得卓越的检测性能。两种技术互相补充完善,可获得优质图像、高检出率和准确的缺陷表征。 | 应用

|