Background

Gasoline and diesel automobile engines have slender air passages, fuel passages, and fuel injectors. The fuel injection section has small holes (1 mm and less in diameter). Machining fuel injector holes requires the utmost accuracy to endure air pressures of 2000 bar and more.

Problem

Electrical Discharge Machining (EDM) is used to fabricate injector holes. Whisker-like cutting chips are almost always produced at the crossing of holes. If these cutting chips remain inside the holes, they will be torn off during engine operation and resultantly block the injection holes. Therefore, an inspection is conducted to check for complete removal of the cutting chips from the holes. Holes fabricated by the EDM method have rough surfaces, which easily generate burrs.

Since one cylinder requires at least one injector, four injectors must be installed to a four-cylinder engine, eight injectors must be installed an eight-cylinder engine, and so on. Injectors are manufactured according to the number of cylinders. All injectors must be inspected; therefore, industrial endoscopes have been used to check the existence of cutting chips and burrs inside the injector holes accurately and efficiently.

Benefits specific to Olympus

Injector holes are 3 mm or less in diameter and about 100 mm in length. Inspection inside such a slender hole is limited to specially designed needle endoscopes. Olympus offers miniborescopes - needle rigid borescopes in 1.2 mm, 1.7 mm, and 2.7 mm diameters. Olympus also offers a 2.4 mm diameter videoscope. These Olympus borescopes and videoscopes provide clear, high-quality images to detect tiny defects and feature excellent durability. Olympus miniborescopes minimize outer periphery distortions, resulting in clearly focused images from center to edge.

Images from Olympus borescopes and videoscopes can be magnified on external monitors for quick and easy inspection of injector holes, contributing to improvement of productivity.

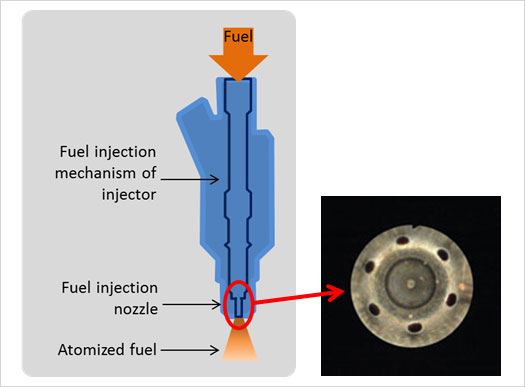

[Left: Schematic of injector interior

Right: Inspection image captured by Olympus MK modular Mini-Scope of the inside of an injector nozzle. The nozzle has ports that inject atomized fuel.]

There is a limitation on the combination of our miniborescopes with light sources and light guides. For more information, contact your Olympus representative.