Introduction:

In today’s pipeline industry, corrosion resistant alloys (CRAs) are widely used to help protect pipelines that transport corrosive fluids. Various combinations of CRA materials and thicknesses are used. In many cases, the parent material of the pipe is carbon steel with a layer of CRA bonded to the inside. The weld that joins pipe segments together is also made of the CRA material.

Challenges of CRA weld inspection

When inspecting a weld with phased array pulse-echo or pitch-catch standard configurations, the ultrasonic beam rebounds at the bottom of the part so that the beam’s second leg passes through the weld bevel and cap area. However, when a CRA is bonded to the inside of the pipe, the alloy often has properties, such as grain structure and velocity, that differ from the pipe’s parent material. The layer of CRA creates mode conversions which make data analysis extremely difficult. To avoid the need of a rebound, a phased array probe with longitudinal waves can be set up to pulse on the opposite side of the weld bevel. However, CRAs are generally more attenuating, which results in a decreased signal-to-noise ratio and, consequently, poor beam penetration. In addition, the upper portion of the weld, with potential surface and sub-surface indications, remains uninspected.

Solution: Dual linear array probes to inspect CRA welds with the PipeWIZARD system

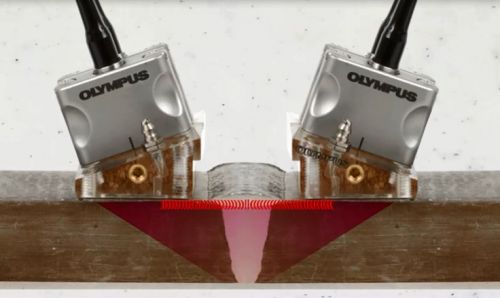

A dual linear phased array (DLA) probe can be fixed to the PipeWIZARD scanner and used to inspect the dissimilar welds (Figure 1). The required equipment includes:

- PipeWIZARD with latest software version (U8110022)

- 4QL15-A27 dual linear phased array probes (Q3300143)

- Two SA27-DNCR-IRC-AODx or SA27-DN55L-FDx-IRC-AODx wedges

- Two PipeWIZARD rings for SA27-IRC wedges (Q1100053)

- Two PipeWIZARD forks for SA27-IRC rings (Q1100054)

Advantages of the technique

DLA probe with the PipeWIZARD enables the complete and accurate inspection of welds in CRA clad pipelines. The chief advantages of this technique include:

- The benefits of phased array S-scans are combined with low frequency transmit-receive longitudinal (TRL) inspection for better penetration in highly attenuating materials.

- Transmit-receive configuration enables low profile and small foot print wedges to be used, eliminating the need for the wedge damping material and large standoff normally required with longitudinal pulse-echo inspections.

- Signal-to-noise ratio is improved by being able to position the probe closer to the weld, resulting in a shorter UT path.

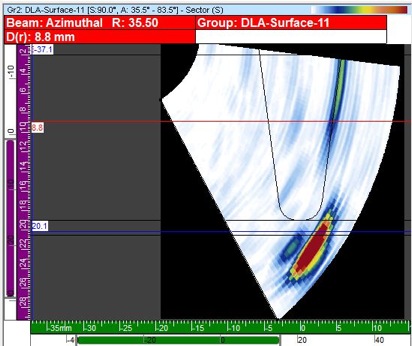

- The high angle of inspection ensures that the surface and sub-surface areas of the weld are inspected with no back wall rebound.

Figure 2: S-scan imaging of an indication in a CRA weld.

Conclusion

A dual linear phased array probe in quad configuration can be fixed to the PipeWIZARD scanner for efficient inspection of CRA pipelines with dissimilar girth welds. The probe and wedges enable complete coverage of the weld in one pass with simultaneous inspection on both sides. The data quality is improved since the weld is inspected using only the ultrasonic beam’s first leg, eliminating the need for rebound to inspect the weld. This also results in a better signal-to-noise ratio and better penetration.

Since various combinations of materials and thicknesses can be used for CRA, the optimum inspection technique must always be defined for each project. Detection and sizing accuracy limits can only be determined by trials, so we recommended performing tests on a calibration block of the same material as the pipeline that is going to be inspected. Olympus will continue to provide advanced tools to support new challenges in the pipeline industry.