Did you ever notice that when you open a yogurt cup, sometimes yogurt is sticking to it and sometimes it’s not? Why does this happen?

Turns out, the answer lies in the level of water repellency on the lid—yogurt will stick to a lid with lower water repellency but won’t stick to one with higher water repellency.

Water repellency is just one of the many properties added to treat the surface of films used in food packaging so that they perform specific functions. Various functions are required for food packaging, such as:

- Maintaining the freshness and quality of the food

- Making it easy for consumers to handle, such as opening the packaging

- Creating a contaminant-resistant surface

The demand for certain functions in food packaging, such as the reduction of food loss by reducing adhesion, is increasing. Packaging technology is evolving accordingly. These treatments added to the surface of film must be checked for quality, an inspection measured through surface roughness.

Surface roughness inspection, often done with a 3D laser confocal microscope, measures the roughness of fine irregularities on the film surface and quantifies it numerically. In my latest experiment, I used a LEXT™ OLS5100 3D laser confocal microscope to investigate the relationship between water repellency and surface roughness using two different yogurt lids.

Keep reading to see the results!

Checking the Visual Surface Condition on the Yogurt Lids

First, I looked at the visual surface condition on the back of the yogurt lids in 3D using the OLS5100 laser confocal microscope.

The lids are composed of multiple film layers, including an aluminum layer with strong reflective properties. To correctly capture the shape of the outermost surface of the film, it is important to take data that’s not affected by strong reflection from the lower aluminum layer. Using a high-magnification objective lens with a shallow depth of focus reduces the effect of strong reflection from the lower layer and enables data to be acquired only on the outermost surface of the film.

The OLS5100 microscope is adapted to a laser wavelength of 405 nm and uses a dedicated LEXT objective lens that suppresses aberrations. With this setup, accurate data can be acquired over the entire field of view.

Dedicated LEXT objectives from left to right: 10X low magnification objective, 20X, 50X, and 100X high-performance objectives, and 20X, 50X, and 100X long working distance objectives.

The 3D data acquisition makes it visually clear that the highly water-repellent yogurt lid has spherical convex aggregates of various sizes randomly scattered on the base surface. In contrast, the lid with low water repellency has no conspicuous convex shape.

Visual 3D data of the two yogurt lids taken with the OLS5100 laser confocal microscope. Left: yogurt lid with high water repellency (50X objective, about 250 µm). Right: yogurt lid with low water repellency (50X objective, about 250 µm).

To understand the surface condition of a sample with high water repellency, consider the surfaces of lotus leaves and broccoli. You may have seen these surfaces repel water and the water droplets flow down. These surfaces have a fine uneven shape called a fractal structure. Thanks to this shape, water can be repelled. A fractal structure is a shape where similar shapes can be seen on different scales.

Inspired by these natural shapes, this fractal structure is also applied to highly water-repellent yogurt lids. In the example above, the data for one field of view (about 250 µm) is shown using a 50X objective lens.

Acquiring Surface Roughness Data in a Wider Field of View

Next, I acquired the data from a wider area to see what kind of distribution this characteristic convex shape has on the back of the highly water-repellent yogurt lid.

A high-magnification objective lens is effective for acquiring data only on the outermost surface of the back side of the lid. However, the range of one field of view is too narrow to capture all the data.

The stitching function on the OLS5100 microscope enables you to connect individual images captured using a high-magnification objective lens to create a high-resolution image in a wider field of view.

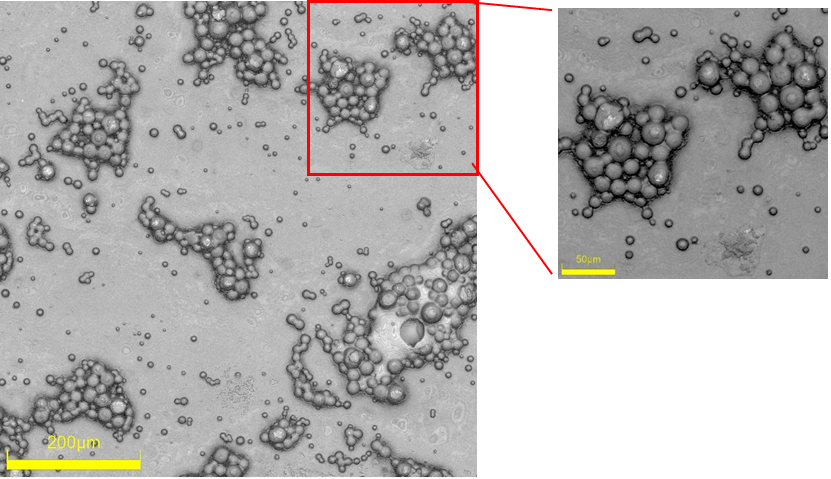

Below you can see that the appearance of the convex aggregates randomly scattered in one field of view (right) has a similar distribution even when the field of view is widened (left). The convex aggregates have a fractal structure.

Left: 3 × 3 stitched images (50X objective, about 700 µm). Right: one field of view (50X objective, about 250 µm).

Quantifying the Surface Condition of the Yogurt Lids

The images above show visually that:

- The surface states of highly water-repellent films and low water-repellent films differ greatly

- Convex aggregates exist in highly water-repellent films

- The convex aggregates have a fractal structure where similar convex aggregates are scattered even when the images are stitched together and observed in one wide field of view

Based on these results, I quantified the surface condition of these two lids by measuring their surface roughness on the OLS5100 3D laser confocal microscope.

Generally, a stylus-type surface roughness tester that acquires one-line data is often used for roughness evaluation. However, for shapes with locally scattered irregularities, such as on highly water-repellent surfaces, the roughness value varies greatly depending on the line traced by the stylus. Further, contact with the stylus can damage the sample, which presents a risk during measurement.

In contrast, a 3D laser confocal microscope can obtain surface data without contact. It does so by scanning the laser beam. This process makes it possible to obtain more surface shape information than the one-line data from the stylus.

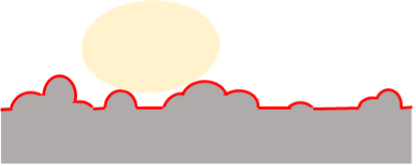

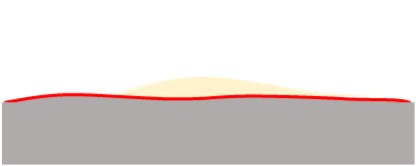

Left: the stylus can damage the sample’s surface. Right: non-contact measurement using a 3D laser confocal microscope doesn’t damage the sample.

Left: data from a stylus-type surface roughness tester provides information from only one line. Right: the OLS5100 3D laser confocal microscope acquires information from an entire plane.

The acquired data from the wide field of view (about 700 µm) was used for the surface roughness measurement.

To obtain data suitable for surface roughness, it is important to evaluate with a field of view that contains at least 10 characteristic uneven shape components that can affect the surface function of the sample the most.

Let’s consider what this means for the highly water-repellent sample above. Assuming that each convex aggregate seen in the one field of view (50X objective, about 250 µm) is a characteristic shape component that provides a water-repellent function, we need at least 10 convex aggregates captured in a wider field of view. To collect more than 10 convex aggregates, I used widefield data with 3 × 3 stitched images to evaluate the surface roughness.

Surface Roughness Measurement Results of the Two Yogurt Lids

Using the 50X objective lens, the 3D laser microscope obtained the following results for the back surface of the two lids:

| Sample | Sp [µm] | Sv [µm] | Sz [µm] | Sa [µm] | Sdq | Sdr [%] |

|---|---|---|---|---|---|---|

| High water repellency _50×z1_3×3 | 28.419 | 9.597 | 38.016 | 4.297 | 2.082 | 31.562 |

| Low water repellency_50×z1_3×3 | 2.044 | 7.434 | 9.478 | 0.471 | 0.127 | 0.561 |

The parameters to note are Sp, Sz, Sa, Sdq, and Sdr. Here’s an overview of these parameters:

Sz (maximum height) and Sp (maximum mountain height)

If you look at the Sz value, you can see the size of the unevenness from the average surface. Sz is the sum of the maximum mountain height (Sp) and the maximum valley depth (Sv). What we pay attention to here is that the difference between Sp and Sv is large only in Sp. In this example, this data shows that the highly water-repellent lid has many convex shapes from the average surface.

Sa (arithmetic mean height)

Sa shows the average value of the height difference from the average surface. The highly water-repellent lid with a large Sa value has larger unevenness.

Sdq (root mean square gradient)

Sdq shows the average size of the local gradient of the surface irregularities. The highly water-repellent lid with a large Sdq value has larger unevenness, which reduces the gloss of the surface.

Sdr (Expanded interface area ratio)

Sdr shows the rate of increase in surface area. The higher the water repellency, the larger the undulations and the larger the surface area.

Understanding the Water Repellency of Lids Using Surface Roughness Data

Forming the surface of the water-repellant lid into a fractal structure reduces the contact area between the yogurt and the lid. This surface shape causes the yogurt to form droplets that do not stick to the film. The reduction in the contact area means that the surface area of the film is large and uneven. In contrast, the lid with low water repellency has a small, even surface area that creates a large contact area. We can conclude that the yogurt sticks to this lid because the adhesion increases as the contact area increases.

Here is the relationship of the level of water repellency with the surface roughness data:

|  |

| Yogurt lid with high water repellency | Yogurt lid with low water repellency |

| Contact area with yogurt: | Small | Large |

| Unevenness (Sp / Sz / Sa): | Large | Small |

| Local slope of unevenness (Sdq): | Large | Small |

| Surface area (Sdr): | Large | Small |

Related Content

Static Electricity and Surface Roughness in Films: An Experiment

Brochure: LEXT OLS5100 3D Laser Microscope

Surface Roughness Measurement: Practical Tips to Get Started

Get In Touch