Introduction

For many years, quality control for blow molded parts involved cutting them up with utility knives to make thickness measurement with calipers. There are a number of problems with this traditional method of testing. When a part is cut open, a burr is generally left at the cut edge. If the operator makes a measurement over the burr, it is not a true wall measurement. Assuming that the operator is careful and avoids distorted edges, there are still limitations as to where measurements can be made with mechanical devices. Often, the part’s geometry won’t permit access to tight corners or handle areas on bottles. Once a part is destroyed for thickness measurements, it can’t be used for most other testing. Variation in operator technique is frequently a problem. Calipers can cause errors when they are held at an angle to the part, and when calipers are used on materials that can be compressed by jaw pressure, thickness readings will vary from one operator to another. There is a potential safety problem as well. Operators are required to section parts with utility knives several times a shift, which creates a constant possibility of serious injuries.

Two electronic methods that can reduce or eliminate all of these problems are available: ultrasonic gauging and Hall- effect gauging. Both of these methods are now commonly used in blow molding quality control. The selection of a measuring method is generally dependent on the product to be tested, and the factors involved in choosing a method (discussed at the end of this note) are generally dependent on the product to be tested.

Ultrasonic Gauging Theory

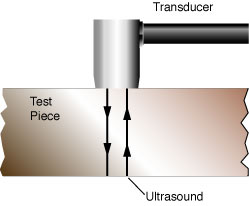

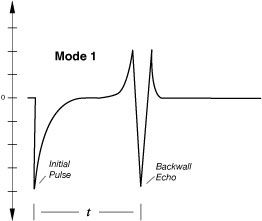

Ultrasonic thickness gauges provide an accurate, reliable, repeatable means of nondestructively measuring wall thickness from one side of the part. They work by measuring the time it takes for an ultrasonic sound wave to travel through the part. The transducer is placed on the surface of the part to be measured and acoustically coupled to the part using a fluid, usually glycerine, propylene glycol, or water. The pulse of sound travels from the contact surface to the opposite surface and bounces back to the transducer as an echo (see Fig. 1). The gauge measures the transmit time of a pulse of sound through a material (see Fig. 2); using the velocity of sound in the material being measured, the gauge calculates the thickness of the material by the following equation.

Figure 1. The transducer is placed on the part. Sound from the transducer makes a round trip between the contact surface and the back surface.

Figure 2. The initial pulse represents sound entering the part. The back wall echo represents sound returning from the opposite surface. “t” is the time of flight 0f the pulse of sound. Mode 1 refers to the measurement method, which used the initial pulse and the back wall echo to determine thickness.

Calibration

Ultrasonic gauges are extremely accurate if the conditions that cause errors are understood and a few simple precautions are taken. If the gauge has been properly calibrated, it will display an accurate wall thickness. The calibration process requires material samples of known thickness. Typically, the gauge will be set up on samples representing the maximum and minimum material thickness to be measured. Material sound velocity and zero offset (a transducer-related parameter) are set by performing a simple keypad operation involving entering the known thickness of reference standards while coupled to the material. The gauge uses the known thickness to calculate a sound velocity and zero offset for that material and transducer, respectively. When the gauge is making thickness measurements, it uses the calibrated velocity to calculate the thickness of the product.

Advantages and Limitations

A primary advantage of ultrasonic gauging is that thickness measurements require access to only one side of the test material, permitting measurement of closed containers, large sheets, and other geometries where access to both sides is difficult or impossible. Gauges are generally handheld and easy to use. A potential limitation is that the measurement accuracy is only as good as the accuracy to which the material and sound velocities are known and there may be inaccuracies if the material sound velocity changes unpredictably. Velocity can be affected by changes in the material’s properties, which include substantial temperature shifts or variations in density. Most plastics exhibit noticeable velocity shifts as the temperature changes by more than 5 °C (10 °F). The easiest way to avoid temperature induced errors is to calibrate and measure at ambient temperature. If that is not possible, calibration and measurement should be made at a known, constant position in the manufacturing process. As most standard transducers will be damaged by contact with parts hotter than approximately 50 °C (122 °F), testing at elevated temperatures is not recommended unless special transducers are used. Heavy wall products, in which the inside of the part stays hot while the outer surface cools, may have large temperature variations from the outside of the part, to the inside. These temperature variations can cause substantial velocity changes through the wall of the part which, in turn, can introduce measurement uncertainties.

Hall-Effect Gauging Theory

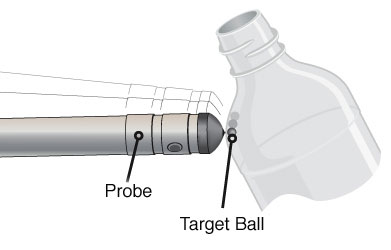

The other electronic gauging method employs a phenomenon known as the Hall effect. The Hall effect uses a magnetic field applied at right angles to a conductor carrying a current. This combination includes a voltage in another direction. A ferromagnetic target such as a steel ball of known mass is placed in the magnetic field and the induced voltage is changed. As the target is moved away from the magnet, the magnetic field and the subsequent induced voltage are changed in a predictable manner. If these changes in the induced voltage are plotted, a curve can be generated that compares induced voltage to the distance of the target from the probe (see Fig. 3).

To make a measurement, a Hall probe is placed on one side of the product to be measured, and a ferromagnetic target (usually a small steel target ball) is placed on the other side of the product. The gauge displays the distance between the target and the probe, which is the wall thickness.

Figure 3. A target ball is placed on one side of a part to be measured. The probe is placed on the opposite of the part, and the ball is attracted to the probe.

Calibration

The instrument is calibrated by placing a series of shims of known thickness on the probe, placing a ball over the shims, and keying into the instrument each known thickness. The information that is keyed into the instrument during the calibration allows the gauge to build a lookup table, in effect plotting a curve of voltage changes. The gauge checks the measured values against the lookup table and displays thickness on a digital readout. While this sounds complicated, operators only need to key in known values during calibration and let the gauge do the comparing and calculating. When Hall-effect gauges are used, it is not necessary for the operator to have knowledge about the physics that enables the measurement as the calibration process is automatic.

Advantages and Limitations

The advantages to this system are that no couplant is used, there is no velocity variation with temperature or other material properties, and wall thickness in tightly radiused areas and in extremely thin samples can be measured. Additionally, it is often easy to scan the probe around the part to quickly verify thickness at a number of points or look for the minimum thickness in an area. The only potential limitation in blow molded plastic applications is that it is necessary to place a target ball inside the part being measured, preventing use on closed containers (which can, however, be measured ultrasonically). The system can measure up to approximately 10 mm (0.400 in.). It can measure compressible materials, but the ball can compress the material, and so the smallest ball possible should be used when making these measurements. In production use, an operator can scan an entire part within a few seconds, while storing several readings or scanning for a minimum wall. Frequently this type of unit is placed in a production area, where it is used by the molding equipment operators. This approach permits true statistical process control.

Selecting a Gauging Method

There are no hard and fast rules for choosing between the two methods. In general, if large, rigid parts with thick walls are to be measured, the preferred method is ultrasonic. When small, thin wall (less than 0.100 in or 2.5 mm.) parts with tight corners are to be measured, Hall-effect gauges such as the Olympus Magna-Mike™ 8600 are preferred. The majority of blow molding applications favor Hall-effect gauges. Most blow molders have parts with complex shapes, relatively thin, flexible walls, and corners that are difficult to measure with mechanical or ultrasonic gauges.

For ultrasonic measurements, any of the Olympus precision thickness gauges can be used. For most common single layer plastic bottle applications, we recommend one of our standard ultrasonic thickness gauges. These include the 38DL PLUS™ and 45MG gauges with Single Element software. Multiple velocity and transducer setups can be stored in these gauges, making gauging of a variety of materials a simple process. M116, M208, or V260 Sonopen™ transducers are commonly recommended for thin-walled parts. For thick-walled parts, use the same gauges with a lower frequency contact transducer (M112, M110, or M109). For thickness measurements on hot plastics at temperatures in excess of 50 °C or 120 °F, use a high-temperature delay line transducer.

For thin bottles under 0.004 in. (0.1 mm) and plastic containers that are multilayer, we recommend the 72DL PLUS™ gauge. Measuring the thickness of thin plastic bottles or multilayer plastic requires the use of a much higher frequency than is available on standard ultrasonic thickness gauges. The 72DL PLUS gauge can use transducers with frequencies up to 125 megahertz and has the ability to simultaneously display the thickness of up to six layers.

Summary

It is possible to calibrate either type of gauge quickly with a few simple steps. Once calibrated, either gauge will produce accurate, repeatable results. Users have found that operator technique is less of a factor with these methods than with mechanical gauging. Calibration data is stored with logged readings and provides a check of the operator’s work. Both the ultrasonic and Hall-effect gauges provide datalogging capabilities, eliminating the possibility of transcription errors.