Aluminum cans used in the beverage industry are routinely inspected for wall thickness. The "old-fashioned" inspection method involved cutting up the cans and then measuring the wall manually. With ultrasonic gauging, wall thickness can be measured instantly and digitally by simply coupling ultrasound into the part from the outside. Generally, taking ultrasonic measurements with a handheld transducer is a straightforward process.

Quality control of deep drawn metal containers, such as heart pacemaker enclosures, can also benefit from ultrasonics. The radiused edges of these enclosures can be very thin and are critical areas for accurate thickness measurements.

Ultrasonic Equipment Used to Measure Wall Thickness of Metal Cans, Containers, and Enclosures

In general, metal wall thicknesses greater than 0.008 in. (0.203 mm) can be measured using the 45MG gauge with Single Element software or the 38DL PLUS gauge with a 20 MHz or 10 MHz delay line transducer to a calibrated accuracy of ±0.0002 in. or ±0.002 mm. Contact transducers are used for thicker metal up to 10 in. (250 mm) or more.

For thin-walled applications with thicknesses below 0.008 in. (0.203 mm), the 72DL PLUS™ high-frequency thickness gauge is recommended. As a high-speed instrument, the 72DL PLUS gauge features a waveform update rate of 60 Hz and a measurement rate of up to 2 kHz. It offers a large, full color touch screen for great visibility from different angles and supports wireless LAN for modern connectivity and integration.

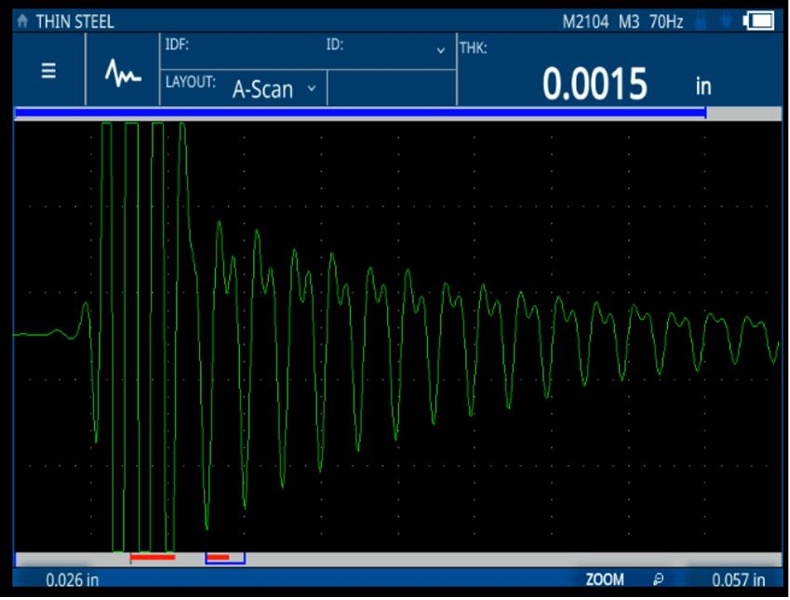

The image below shows an example waveform using the 72DL PLUS gauge with the M2104 (125 MHz) transducer to measure a 0.0015 in. (0.0381 mm) steel sheet.

72DL PLUS gauge measures a thin steel sheet (0.0015 in. or 0.0381 mm) using the M2104 (125 MHz) transducer

Transducer selection depends on the exact application, so contact Evident for guidance. It should be noted that the thickness of aluminum and titanium containers and parts can also be measured with the Magna-Mike™ 8600 Hall-effect thickness gauge . This instrument uses the Hall effect to provide thickness measurements on any non-magnetic material in the range of 0 to 1.0 in. (0 to 25 mm).