Microscope Solutions for

Lithium-Ion Battery Manufacturing

Assembly Process

Laminate the cut electrode sheets. Insert the laminated electrode sheet into the battery container and inject the electrolyte. After discharging unnecessary gas, cover the battery container to complete the battery.

Analyzing the Contamination from Tab Welding

A metal foil called a tab (tab lead), which connects the cells of the battery together, is welded to the anode and cathode. Metal contamination can occur during welding, potentially causing a short circuit. Consequently, it is critical to analyze contamination for quality control after tab welding.

Our Solution

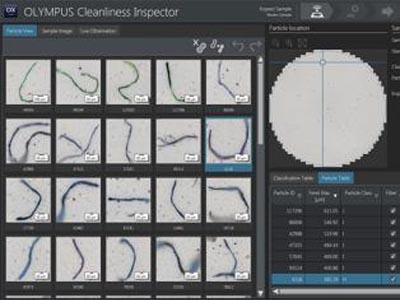

Our OLYMPUS CIX100 cleanliness inspector can analyze metal contamination.

OLYMPUS CIX100 cleanliness inspector |

Application Notes

Explore related applications:

|

|

Inspecting Burrs on the Battery Case

Aluminum alloys are often used for the battery case material. If a burr remains on the case after it is manufactured, a hole might open in the separator or electrode sheet. A hole in the battery seat can lead to an excessive flow of lithium ions, potentially causing the battery to overheat or ignite. To reduce these risks, it is critical to inspect the burrs using a microscope.

Our Solution

Our DSX1000 digital microscope is equipped with a high-resolution lens to detect even the smallest burrs.

DSX series digital microscope |  Cathode Separator Anode |  Battery case |