Routine remote visual inspection is essential for the safe operation of aircraft. With high-quality imaging, interchangeable scopes, and powerful measurement features, our IPLEX™ videoscopes help you detect cracks, erosion, and other critical flaws in jet engines.

High-Quality Imaging

Outstanding image quality helps you quickly locate indications for faster decision making and enhanced efficiency.

Get a clear view of everything from a large space in a combustion chamber to a closeup on a compressor blade.

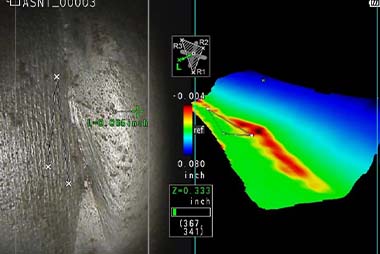

Powerful Measurement Features

IPLEX videoscopes offer powerful measurement features for fast, efficient inspections.

Super wide stereo measurement provides expanded coverage, while 3D modeling makes it easy to choose the right measurement point by showing views of your target from multiple angles.

The Multi Spot-Ranging™ function helps you easily recognize if the videoscope tip is in a measurable range and delivers real-time information about the surface shape during the inspection.

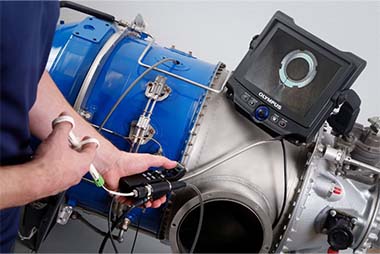

Scopes for Multiple Jobs

Access interchangeable scopes in various diameters and lengths to perform different types of engine inspections with one IPLEX system. Plus, the spare scopes can help reduce downtime if a scope repair is needed.

With similar capabilities as a standard insertion tube, the working channel scope is a useful backup that can also be used for foreign object debris (FOD) detection and retrieval. With a backup scope in your toolbox, you can avoid unnecessary and costly engine removals or teardowns.

Visual Inspection Kits for Aviation Turbines

Our visual inspection kits include IPLEX videoscopes with 3D visual measurement and other recommended tools for high-quality inspections of aviation turbines. Perform efficient inspections with videoscope accessories, such as:

- J-Shaped Tube: A useful guide tube if you want the scope to reach a location that is against the direction of gravity or to move in a certain direction. The J-shape is optimized for general combustion chamber inspections.

- Flex and Stay Tube: Pliable yet rigid tube that can be shaped freely. Easily bend the tube in any shape to reach an object for remote visual inspection.

- Heat-Resistant Sheath: The sheath minimizes the temperature restrictions placed on standard videoscopes for gas turbine and other applications where high-temperature (250 °C, 482 °F) inspection capabilities may be required.

Recommended Kits

Visual Inspection Kits Brochure

Download the brochure now to learn more about

our solutions for aviation turbines.

Learn More about Our Videoscopes

Blog Post

Caring for the Heart of the Aircraft:

Videoscope Inspections Help Enhance Flight Safety

Blog Post

2 Modern Videoscope Capabilities for More Precise Aerospace Inspections

Blog Post

Supporting Military Aircraft Mission Readiness with Fit-for-Service Videoscopes