Did you know that aircraft manufacturers are using more and more composites to construct their planes? The Boeing 787 and Airbus A350 contain over 50% composites. Composites have a significant advantage over other materials because they are lightweight and strong, making these materials ideal for aircraft.

Composites come in two types — honeycomb or carbon fiber reinforced polymers. Honeycomb composites are composed of a honeycomb core sandwiched between thin layers of ‘skin.’ Carbon fiber reinforced polymers, on the other hand, are made up of multiple layers of carbon sheets bound together with a polymer.

Composites can have flaws and discontinuities including disbonds, delaminations, and repaired areas. To help keep air travel safe, the composite parts of airplanes must be inspected.

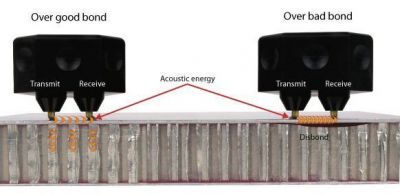

Using acoustic energy, it’s possible to detect discontinuities. Acoustic energy is emitted from one pin on the probe and received at the other pin. Over a flaw-free part, the energy travels on the surface, but part of the energy is dispersed into the composite. When the probe is placed over a discontinuity, the energy only travels on the surface, which increases the amount of energy read by the receiving pin. This is the fundamental principle of composite inspection.

|

| How a bond tester probe works. |

When the probe is used with an OmniScan® MX ECA flaw detector, dedicated software, and probe adaptor, users can easily turn their eddy current flaw detector into a bond testing instrument with intuitive C-scan capabilities.

|

| Some of the instruments inspectors use for composite bond inspection. |

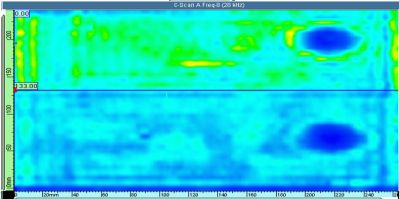

One advantage of the OmniScan MX ECA flaw detector is that it uses 8 frequencies simultaneously, greatly increasing the probability of detection and sizing performance. Every frequency recorded can be analyzed using the amplitude or phase setting, giving the inspector up to 16 C-scans to analyze. The C-scans are in color and help inspectors visualize the discontinuities.

|

| A C-scan image of a composite discontinuity. |

The OmniScan MX ECA flaw detector also supports the GLIDER™ scanner, the WING™ scanner, and a new handheld scanner which all enable raster scanning. Raster scanning helps users locate discontinuities on a recently inspected part; once a discontinuity is found, it can be easily located and repaired or replaced, depending on the severity of the defect.

|

| A new handheld scanner designed to enable raster scanning. |

Conclusion

Testing composite parts for discontinuities using acoustic probes is an important part of maintaining the safety of air travel. Tools like OmniScan MX ECA flaw detector with bond testing add-ons help inspectors do their jobs quickly and efficiently to keep aircraft operating safely.

Get In Touch

.jpg?rev=68D2)