A ball mill is a type of grinder. It’s used to grind or blend materials that are used in many applications including mineral processing, paints, pyrotechnics, and ceramics. The mill consists of a hollow shell that is partially filled with balls (usually steel, ceramic, or rubber). The shell turns on its axis, causing the balls to be lifted up and then cascade down on the material being worked. Particles trapped between the balls are ground down during this process. |

Handheld XRF Helps Reduce Cost and Ensure the Quality of the Grinding Media

Mines and industrial facilities utilize ball mills to grind and blend materials for mineral processing. The highest milling efficiency is achieved with measurable and stable operating conditions. Using balls made from the correct materials helps ensure this stability.

|  |

A ball before (left) and after (right) being used in a grinding mill.

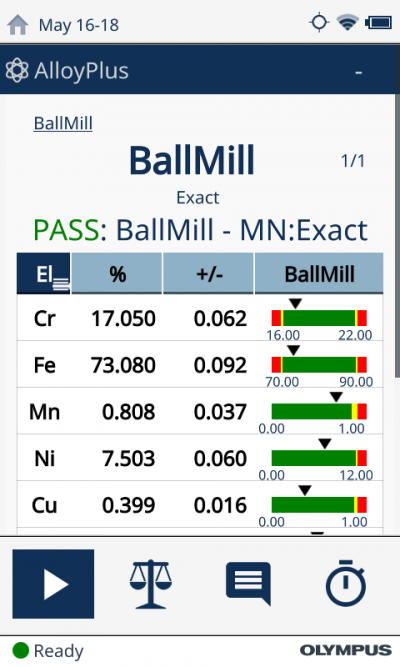

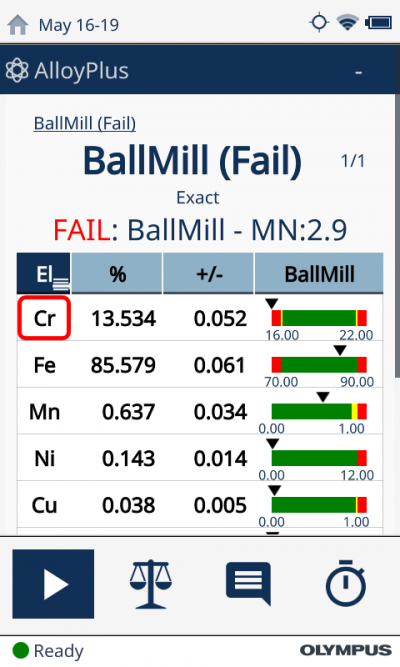

If steel balls are being used in the mill, it’s impossible to tell if they’re made of the correct alloy simply by looking at them. Handheld X-ray fluorescence (XRF) can quickly and reliably verify the material chemistry of a grinding ball to ensure it’s made of the correct alloy. In particular, the amount of chromium (Cr) in the balls is a predictor of durability. One of our customers found that when the chromium concentration dropped below 16%, the balls broke down significantly faster, forcing them to add additional balls to the mill. This is inefficient and expensive as it slows down the milling process and requires the purchase of additional balls. In fact, the cost of the balls is a significant portion of the total mineral processing operation. As a result, the customer pushed their supplier to provide grinding balls with a consistently high (above 16%) level of chromium, increasing the efficiency of their process and lowering costs.

Results of ball mill testing using a Vanta XRF analyzer. The results on the left show the ball passed with 17% chromium content while the ball on the right failed with only 13.5% chromium content.

Related Content

Improving the Metal Manufacturing and Recycling Process Using Portable XRF and XRD

Handheld XRF for Flow Accelerated Corrosion Prediction by Chromium in Carbon Steel