Overview

Although time-of-flight diffraction (TOFD) can be used for a variety of applications, its primary use is rapid weld testing of circumferential and axial weld seams, also known as perpendicular TOFD scanning. Since the introduction of TOFD in the 1970s, the use of this reputed reliable nondestructive testing technique has steadily increased. Manual execution is possible with TOFD, however, it is most commonly performed in combination with a recording device, that is, an encoder or industrial scanner. To achieve code compliance in North America, TOFD is often coupled with pulse-echo or phased array techniques in order to cover the root and cap regions of the weld.

Popular TOFD Weld Inspection Techniques

TOFD can be used indepentently or in conjuntion with other ultrasonic techniques. Some of the most common techniques are:

- Single group TOFD

- Multiple TOFD

- TOFD with pulse echo/creeping waves

- TOFD with phased array

TOFD Basic Theory

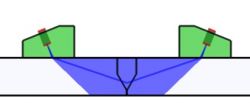

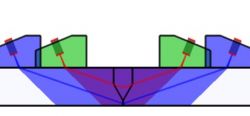

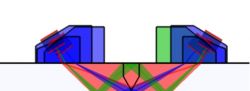

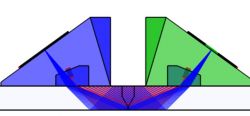

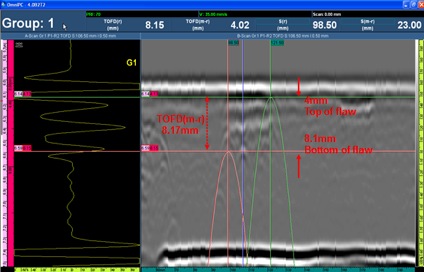

TOFD is usually performed using longitudinal waves as the primary detection method. Ultrasonic sensors are placed on each side of the weld. One sensor sends the ultrasonic beam into the material and the other sensor receives reflected and diffracted ultrasound from anomalies and geometric reflectors. TOFD provides a wide area of coverage with a single beam by exploiting ultrasonic beam spread theory inside the wedge and the inspected material. When the beam comes in contact with the tip of a flaw, or crack, diffracted energy is cast in all directions. Measuring the time of flight of the diffracted beams enables accurate and reliable flaw detection and sizing, even if the crack is off-oriented to the intial beam direction. During typical TOFD inspections, A-scans are collected and used to create B-scan (side view) images of the weld. Analysis is done on the acquisition unit or in post-analysis software, positioning cursors to measure the length and through-wall height of flaws.

Reflected and diffracted sound illustration

Example of TOFD cursor sizing of defect height

Main Benefits of TOFD for Weld Inspection

- Based on diffraction, so relatively indifferent to weld bevel angles and flaw orientation

- Uses time of arrival of signals received from crack tips for accurate defect positioning and sizing

- Precise sizing capability makes it an ideal flaw monitoring method

- Quick to set up and perform an inspection, as a single beam offers a large area of coverage

- Rapid scanning with imaging and full data recording

- Can also be used for corrosion inspections

- Required equipment is more economical than phased array, due to conventional nature (single pulser and reciever) and use of conventional probes

- Highly sensitive to all weld flaw types

Typical TOFD Equipment

- OmniScan SX UT or other OmniScan MX/MX2/SX module, depending on technique

- TOFD scanner – HST-Lite or other

- Highly dampened TOFD probes- CentraScan or other

- TOFD wedges- Rexolite or Stainless Steel

- Optional- Post-analysis and technique development software- NDT Setup Builder and OmniPC

- Water (couplant) delivery system- WTR-SPRAYER-8L or similiar

Conclusion

TOFD offers rapid weld inspection with excellent flaw detection and sizing capacities. The diffraction technique provides critical sizing capability with relative indifference to bevel angle or flaw orientation. TOFD can be utilized on its own or in conjunction with other NDT techniques.