If you’re using a borescope or videoscope in your condition monitoring schedule, we can support you. Our RVI experts have extensive knowledge on wind turbine gearboxes, from their basic internal configuration to performing a borescope inspection of gearbox parts. We can also provide you with training, customized maintenance services, and lease or rental options for the equipment you need (varies by region).

If you read my recent posts on RVI and wind turbines, you’ll know why videoscope inspection is so important and which features to look for when buying a videoscope. The next step is learning how to perform a videoscope inspection of a gearbox and its components.

What’s Inside a Gearbox? Getting to Know the Internal Components

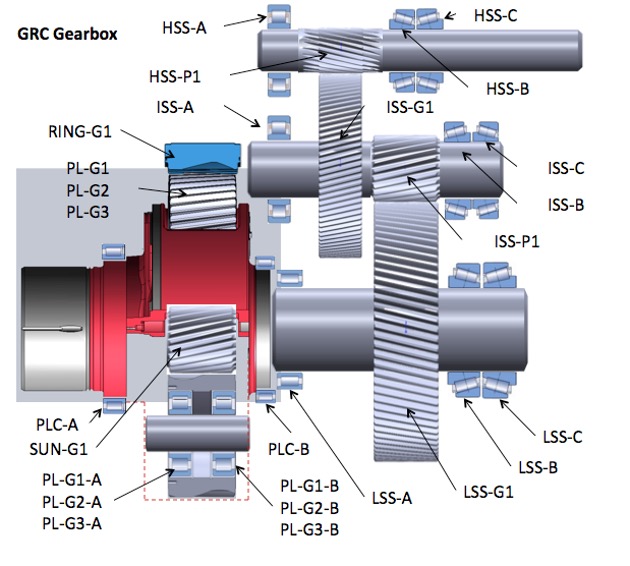

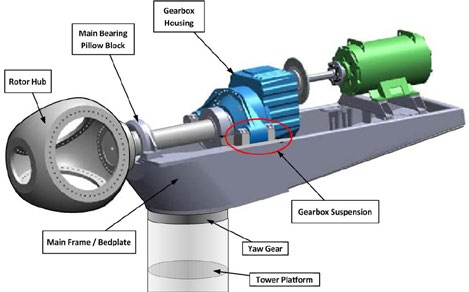

Using a videoscope is straightforward—the complicated part is navigating the gaps between the gearbox’s internal components to access them. A typical gearbox designed for a 2 MW wind turbine has three stages—one planetary stage and two parallel stages. It contains 20 bearings and nine gear wheels, all of which need to be inspected. It’s important to familiarize yourself with these parts and how they look on a videoscope display. And when you know how these parts look in their pristine states, it will help you identify when they degrade or become damaged.

| Legend PLC: Planetary carrier |

| Gearbox internal component schematics (credit https://www.nrel.gov/) |

In this post, I'll give you a general overview of the parts and how you can access and properly view them with the videoscope.

How to Access and Inspect the Planetary Stage with Your Videoscope

The planetary stage has two planetary carrier bearings and nine cylindrical planetary bearings. You can access the planetary stage through small hatches on the rotor side of the gearbox, usually located at around the 2 o’clock and 10 o’clock positions.

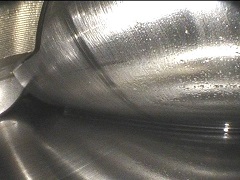

- Ring gear, planetary gears, and sun gear: These gears can be easily inspected with a videoscope through the rotor-side hatches. You’ll want to check the surface condition of their gear teeth, so a near-focus, forward-viewing videoscope is recommended.

Damaged gear teeth with two indentations

Planetary bearings: Thread the videoscope through the space between the planetary carrier and planetary wheel to reach the planetary bearings. Using a bent guide tube will help you prevent the lens from touching the oily surfaces inside the gearbox, and our oil clearing lens adaptor can also improve your view. Since there are three planetary wheels, you’ll have to rotate the rotor to access the two other sets of planetary bearings.

- Rotor side carrier bearings: Insert the scope between the planetary carrier and the gearbox’s rotor side wall to inspect the rotor side carrier bearings. The generator side carrier bearing inspection is sometimes difficult as it is located far from the front hatch. You should try the parallel stage hatch on top of the gearbox as some gearboxes have a large opening between the planetary and parallel stages. If that's not possible, you should use a long guide tube from the front

hatch to reach the generator side carrier bearing.

Image used with permission from Wind Driven LLC.

Undamaged bearing

Bearing with flaking damage

How to Access and Inspect Both Parallel Stages with Your Videoscope

The two parallel stages have three shafts, each with one cylindrical roller bearing and two tapered roller bearings for shaft axial load and guidance. You can access the parallel stages through the large hatch on top of the gearbox.

- High, intermediate, and low speed gears, pinions, and bearings: The access hatch on top of the gearbox is large enough to use a regular digital camera to take photos of these gears and pinions. However, you need a videoscope to check the condition of the bearings.

- High-speed shaft (HSS) bearings: These bearings are usually located near the access hatch on top of the gearbox. So, you can hold the videoscope with your hand to insert the videoscope head between the roller bearings.

- Intermediate-speed shaft (IMS) and low-speed shaft (LSS) bearings: Use the access hatch on the top, but you’ll need a guide tube to be able to insert the videoscope far enough to reach them.

Important Safety Tip—Avoid Breathing Oily Vapor

The temperature inside a wind turbine gearbox reaches up to 70 °C (158 °F) during operation. If you stop the wind turbine and open the gearbox hatches, a hot oily vapor is released. To avoid breathing in the vapor, you should open the nacelle windows or roof before opening the gearbox hatches. Then wait at least 30 minutes at the deck below the gearbox before starting your videoscope inspection.

Data Management Tip—Organize Images to Localize Parts

Another helpful tip to speed up data management is to prepare the image folders (as explained in #5 of the second blog post in this series) in advance. Our InHelp™ inspection assist software is a useful tool for making sure your image data is well organized.

Guide to Borescope and Videoscope Training Programs

Our RVI experts can provide helpful guidance and practical tips for your gearbox inspection and building a maintenance program. Below is a list of some of our training and assistance resources.

Olympus Borescope and Videoscope Training Programs

We offer customized borescope/videoscope training at your site or at Olympus offices. We’ll teach you how to use all the functions of our IPLEX videoscopes, as well as proper equipment care. It’s important to maintain the condition of the videoscope to maximize its performance. Learn more about our Training Academy.

How to Clean Your Videoscope or Borescope

With oily gearbox inspections, knowing how to clean the videoscope and lens is essential to ensure your images are high enough quality. Watch our short video tutorial to learn how to clean your videoscope.

Wind Academy Borescope Training Programs

In some countries, Olympus has a partnership with wind academy organizations for gearbox inspection borescope and videoscope training. Contact your local Olympus representative if you’re interested.

OEM Borescope Training Programs

Some gearbox manufacturers and overhaul companies offer gearbox borescope training. Check whether your gearbox manufacturer offers borescope training services on their website.

Videoscope Lease and Rental Services

Olympus also offers financing or operating lease agreements as well as videoscope rentals in certain regions. Contact your local Olympus representative to find out what’s available where you are.

If you have any further questions, don’t hesitate to contact us for all your RVI-related inquiries. Our experts are at your service.

Related Content

IPLEX™ G Series Wind Turbine Inspection Solutions

Inspection of Wind Turbine Gearboxes

Wind Turbine Gearbox Inspections at ALL NRG

Get In Touch