Where to start? It’s a valid question for surface roughness measurements, as there are two significant sources of confusion.

The first is determining the method to perform the measurement. Many instruments can perform surface roughness measurements, each with unique advantages and disadvantages, so it can be difficult to select the best one for each sample.

The second confusing part is understanding the meaning of the measurement. Hundreds of roughness parameters can be derived from the captured data, so it can be difficult to determine which ones are relevant to an application.

This post explains these challenges in detail and provides ideas to make all parts of the roughness measurement inspection easy and efficient.

Performing Surface Roughness Measurements

In the past, operators took surface roughness measurements with simple handheld gauges. Data output was manual, analysis required a separate process, and measurements were time-consuming and prone to errors.

Today, many instruments offer a more efficient workflow and a user-friendly interface with data displays, touch screens, network connectivity, and computers to process the data. All these enhancements have considerably improved productivity.

As systems continue to advance, the need for accuracy has become even more important than productivity. Maximum requirements for surface finish are now stricter, commonly in the range of 6–8 µin, and require high-resolution instruments.

Comparing High-Resolution Instruments: Which Is Best for Surface Roughness Measurement?

One high-resolution instrument is the atomic force microscope, which can complete roughness measurements with near-atomic height resolution. Yet, this microscope has a slow scanning speed and limited scanning area. This technique is unsuitable for large samples, particularly those with curved surfaces, where a large scanning area is required for meaningful results.

Important considerations like this mean you need to carefully select an inspection instrument based on different factors, including throughput, resolution, and scanning range.

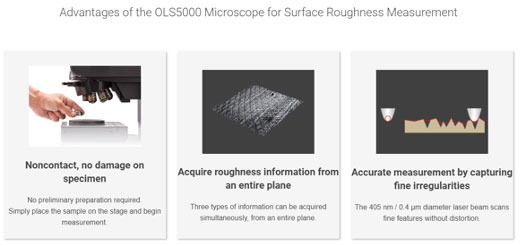

In contrast, optical instruments like laser scanning confocal microscopes enable you to quickly generate 3D images of relatively large samples with high resolution. This nondestructive technique can also examine rough surfaces with cavities that are hard to reach for stylus profilometers.

With a 3D image, you can quickly locate the area of interest and will know exactly where the data is collected. These advantages greatly reduce measurement time and improve accuracy when dealing with small samples and microscopic features.

With optical systems like our LEXT™ OLS5000 laser scanning confocal microscope, accuracy and repeatability are guaranteed after calibration with traceable standards, so you can perform inspections with confidence in your results.

The OLS5000 confocal microscope is a powerful tool that can help you quickly scan surface features and take accurate measurements

Understanding the Meaning of Surface Roughness Measurements

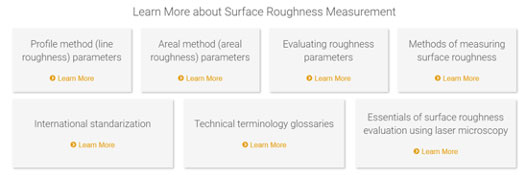

Once a measurement is completed, the next step is to figure out its meaning. Information on roughness is usually captured with a single parameter, Ra. Yet, Ra only captures limited information on surface topography variations. It doesn’t capture any information on the density of asperities, or the period or shape of regular patterns.

The limited information from Ra forced engineers to define additional roughness parameters that quantify characteristics such as period, shape, sharpness, volume, and predominant orientation. The software for our LEXT OLS5000 laser confocal microscope can derive close to a hundred parameters, which are conveniently organized into different categories aligned with specific types of applications.

For example, volume parameters quantify the volume of surface asperities and pits, which is critical information for lubrication and wear studies. Feature parameters, such as peak density and average curvature, characterize the effect of surface treatment and texture in additive manufacturing. You must understand the meaning of these parameters and identify the one that is most relevant to the application.

Practical Tips for Surface Roughness Measurement

Optical systems like our LEXT confocal microscope can overcome many challenges related to surface roughness measurements. To learn more about the microscope and discover practical tips for surface roughness measurement, explore our comprehensive surface roughness portal.

Explore methods, techniques, and helpful tips online using Olympus’ surface roughness portal

Related Content

Webinar: 5 Things You Need to Know About Surface Metrology

Surface Roughness Measurement Portal

4 Tips for Using the Advanced Optical Metrology Hub for Work and Research

.jpg?rev=4DBD)