Traveling at 170 miles per hour, a nearly 100-ton aircraft skims the surface above the tarmac. A few seconds later, the airplane touches down, small puffs of smoke emerging from the tires when they touch the ground.

This scene occurs thousands of times a day.

Airplane wheels are essential for ensuring that each landing happens safely. They experience a tremendous amount of stress and brake-generated heat during landing, so they must be strong. But they also need to be lightweight. Consequently, most wheels are made from an aluminum alloy. To help ensure they maintain their structural integrity, the wheels are regularly inspected using eddy current technology, a nondestructive testing technique that enables trained operators to detect cracks and flaws in the wheel.

Testing with Eddy Current Technology

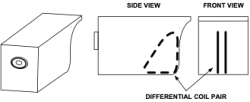

Eddy current testing uses electromagnetic induction to detect surface cracks and defects. But not all eddy current tests are created equal. Many inspections are carried out with single-element eddy current pencil probes. As the name implies, these probes have a small tip. While they’re effective at inspecting aircraft wheels, their small size makes these inspections a time-consuming job. However, using a custom-shaped probe specifically designed for wheels makes this process faster and more efficient.

Advanced Manufacturing

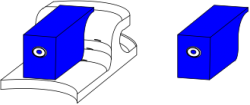

The critical nature of aircraft wheel inspection prompted us to develop new manufacturing technologies to improve the process. Incorporating 3D printing technology enabled us to create custom probes for wheel inspection quickly. And because we can manufacture probes with high precision, it helps ensure that the probes provide repeatable data. The process begins when a customer provides us with a CAD drawing of a wheel or sends us an actual wheel to work with. If they send us a wheel, we use a coordinate-measuring machine (CMM) to get exact measurements, which we convert into a CAD drawing. Once we have an exact drawing, we send the data to a 3D printer. Using a 3D printer, we can print the probe’s coil bobbins instead of having to place the coils by hand, greatly improving the probe’s repeatability. To improve the data quality, we manufacture the eddy current probes to precisely fit a specific wheel radius. The result of this manufacturing process is probes that are reliable, repeatable, and that can be made quickly. |

Custom Probes Improve Inspection

Using one of our custom probes, most wheels can be inspected in a single pass, leading to significant time savings. The shape of the probe covers the entire bead seat area almost perfectly, increasing the probability of detection. |

More than Just Aircraft Wheels

Advanced manufacturing technology gives us the flexibility to design custom probes for many applications, including just about any kind of wheel. We’ve also created probes to inspect rollercoaster, semitruck, and trailer wheels (to name a few). Our custom wheel probes are popular because they offer many advantages:

|

Related Content

Through Thick and Thin: Using XRF to Measure Coating Thickness

Did You Know? We Custom Manufacture Probes for Your Specific Applications

Bring the Noise! How Sound Helps Keep Airplanes Safe

Get In Touch