Are you ensuring end-to-end quality of your finished goods? For mission critical applications, it’s important to maintain high quality standards in all steps of your supply chain—from incoming goods, to manufacturing, to final assembly. One technology that can improve your quality process is handheld X-ray fluorescence (XRF).

This blog will explore the benefits of handheld X-ray fluorescence for QA/QC and provide XRF tips for end-to-end manufacturing quality control.

Advantages of Using Handheld XRF Analyzers for Manufacturing QA/QC

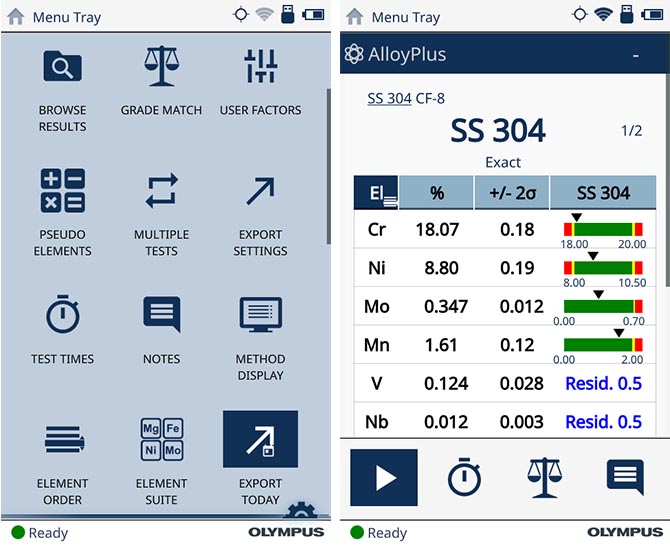

Handheld X-ray fluorescence is a technique for verifying metal composition. It provides accurate elemental analysis and grade identification. You can use handheld XRF to test a variety of materials, including sheets, rods, tubes, bars, wires, powder, and finished products, making it a handy tool for material verification. Other benefits include:

- Minimal sample prep: testing alloys requires no or minimal sample preparation in most cases.

- Nondestructive: handheld XRF doesn’t leave a mark on tested metal alloys.

- Ease of use: simply position the analyzer, pull the trigger, and test results for common alloy grades appear in seconds.

- Fast analysis: for common alloy grades, testing only takes 1-2 seconds for immediate results.

- Portable: handheld XRF analyzers are lightweight, portable, and can be used throughout your facility.

Now that you know the advantages of handheld XRF for QA/QC and material verification, we’ll review some helpful tips to help you get the most out of your analyzer.

9 Ways to Use Your XRF Analyzer for End-to-End Manufacturing Quality Control

Here are some ways you can use your Vanta™ XRF analyzer to help ensure quality control throughout your process:

1. Verify materials all day throughout your facility.

Vanta handheld XRF analyzers are drop tested and IP rated for greater durability and uptime in manufacturing environments, so your team can make fast decisions about material quality and stay productive all day long.

2. Reduce time spent training operators with user-friendly software.

The Vanta analyzer’s simple user interface is easy to follow with smartphone-like operation. Customizable operator instructions and clear pass/fail results make the analyzer easy to learn and easy to use, reducing the risk of human error.

The Vanta analyzer’s UI is similar to a smartphone to reduce user training and improve productivity.

3. Customize the grade library for your application.

With over 600 unique grades in the editable grade library, matching grades is easy. The residual tramp library is based on industry standards to simplify grade matching.

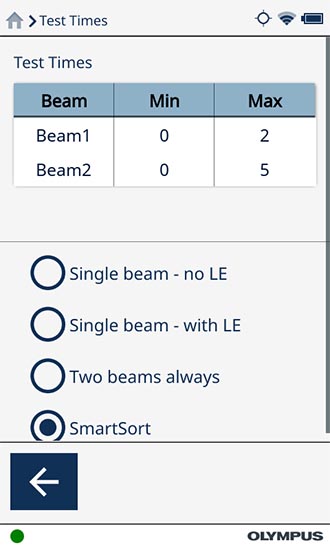

4. Ensure high test throughput with SmartSort.

SmartSort automatically extends testing for light elements (e.g., magnesium, aluminum, and silicon) when necessary and eliminates unnecessarily long tests.

Use SmartSort to save time on testing.

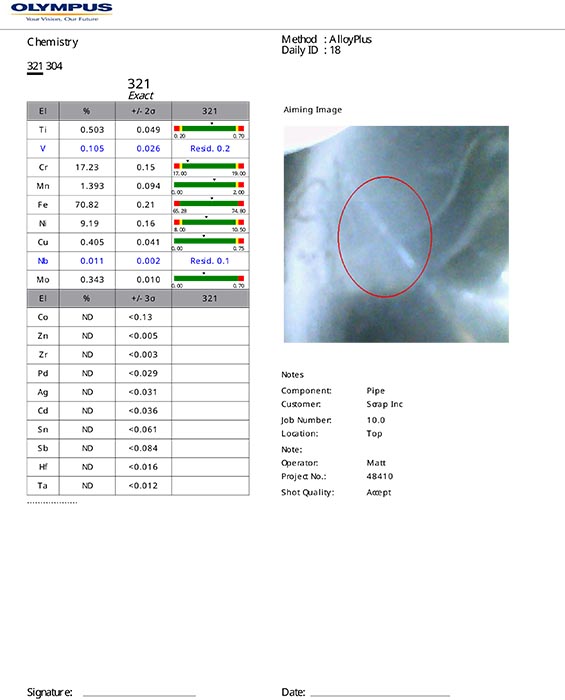

5. Take a snapshot.

Save and archive a photographic record of your tested materials for greater visibility and reporting.

Take a quick snapshot with the Vanta analyzer’s camera to capture a visual record of the tested material.

6. Isolate the area with the collimator.

The analyzer’s optional collimator helps you isolate small features from the background materials, a useful feature for testing small components and welds.

7. Use the panoramic camera as a barcode scanner.

Use the Vanta analyzer’s optional panoramic camera as a barcode scanner, then automatically populate the embedded information into your test note.

8. Connect wirelessly to simplify data management.

Leverage the optional wireless capabilities to seamlessly integrate XRF data into your ERP system and help ensure compliance with purchase specifications. You can also connect to the Olympus Scientific Cloud™ (OSC) to access free and paid apps designed to simplify data sharing.

9. Use onboard reporting to streamline record keeping and traceability.

Use the onboard PDF reporting to combine GPS data, images, and XRF test information into a neat summarized report. You can easily reference it to find the date/time stamp, operator notes, and more.

Convenient onboard PDF reporting on Vanta analyzers helps you streamline record keeping and traceability to the field.

The Importance of End-to-End Quality

Improved quality means better products, reduced costs, and higher customer satisfaction. Taking advantage of these powerful XRF analyzer capabilities can help you maintain high quality standards in all steps of your process. To learn more about how handheld XRF can improve your quality program, check out this resource next: Vanta Analyzers for Manufacturing QA/QC.

Related Content

Brochure: Vanta XRF Analyzers for Manufacturing QA/QC

Infographic: Save Time and Prevent Material Mix-Ups with Vanta Handheld XRF

Video: Vanta XRF Analyzer Overview

Get In Touch