In the power generation, oil gas, and chemical industries, reducing the downtime of rotating machinery such as turbines is a key factor for plant efficiency and profitability. The use of the latest videoscopes with a wide field of view, expanded measurement capabilities, and easy-to-use software enables inspectors to obtain detailed images and measurements quickly and make their inspections more efficient for maximized uptime.

Plant inspection is a crucial yet challenging environment due to the wide range of equipment. Rotating machinery such as turbines, pumps, generators, compressors, and gearboxes experience constant stresses and strains, and require regular inspection to prevent failures or to maintain high fuel efficiency. Regular checks help to detect, identify, and quantify different types of defects and damage (Figure 1).

Figure 1—The rotating parts of a turbine require regular inspection to maintain safety and efficient operation.

Speed Up Inspection

The output—and therefore the profitability—of rotating equipment is often directly related to its uptime. Since rotating equipment needs to be switched off (and sometimes cooled down) for inspection, technologies that speed up this process quickly generate a high return on investment. Remote visual inspection (RVI) is a commonly used method to view hard-to-reach areas of rotating machinery. The latest generation of remote visual inspection equipment, such as Olympus’ IPLEX NX® videoscope (Figure 2), are well suited for this type of inspection, due to their bright illumination, intuitive maneuverability, and easy-to-use software. |

Large Components

|  |  |

Figure 3—InHelp™ software enables one-click scoring and sorting, leading to faster report generation.

Wide Field of View

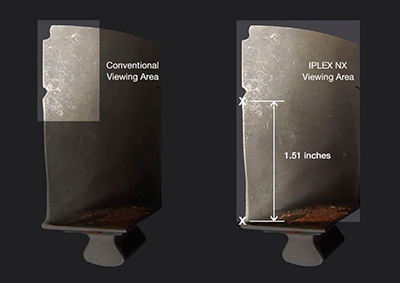

Designed to speed up imaging and measurements of large components, such as turbine blades, the IPLEX NX videoscope a has viewing area four times larger when compared to conventional videoscopes (Figure 4). The larger area means that it is easier to get a suitable overview of a large component without needing to stitch multiple images together. This makes the RVI workflow easier and faster. The improved viewing area also means that measurements become more straightforward. When finding a defect, inspectors often need to quantify it as well. This can mean, for example, that inspectors must measure the distance between the defect and the root of a blade or determine the dimension of a crack. With a large viewing angle, measurements do not need to be based on two separate images, enabling both speed and precision. |  Figure 4—The four times larger viewing area of the IPLEX NX videoscope facilitates both imaging and the measurement of defects.. |

Inspect. Sort. Report.

Another key aspect that determines RVI efficiency is the way in which the videoscope’s software aids the annotation and sorting of images and the way it creates reports. During an inspection, the technician often generates many images that need to be managed adequately, usually with only one hand free to operate the base unit of the videoscope, to create clear reports.

With Olympus’ InHelp image management and reporting software, images can easily be annotated and sorted during the inspection. It also enables inspectors to score defects based on the severity of the damage (Figure 3) with only one click. These features make report generation faster and easier, while also reducing the risk of human errors.

Summary

Due to the high costs associated with downtime of rotating machinery, fast inspections are highly beneficial to plant output. The Olympus IPLEX NX videoscope is well suited for RVI inspections in the oil gas, chemical, and power generation industries due to the many features dedicated to fast and reliable inspections. Wide angle measurements and easy-to-use software, along with bright illumination and adaptive articulation, help the IPLEX NX videoscope minimize downtime and maximize plant profitability.