Introduction

The seamless tube manufacturing process can generate flaws in various angles around the longitudinal axis of a tube. These flaws, introduced primarily during the lamination or heat treatment process, can cause the tube to fail while in use, potentially leading to catastrophic economic and social impacts.

Challenges

To ensure the integrity of their products, seamless tube manufacturers must maintain stringent quality standards. For this reason, they need to use the most reliable and precise inspection methods available. However, many conventional automated phased array ultrasonic testing (PAUT) tube inspection systems assume that the manufacturing process generates flaws at certain discrete angles, which is not always the case.

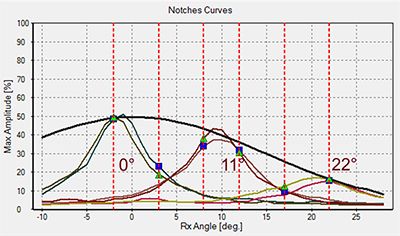

With the current PAUT method, to ensure inspection coverage for a range of oblique angles, the reference standard used for calibration would need to contain several notches at different angles, and each of them would need to be calibrated individually.

Solution

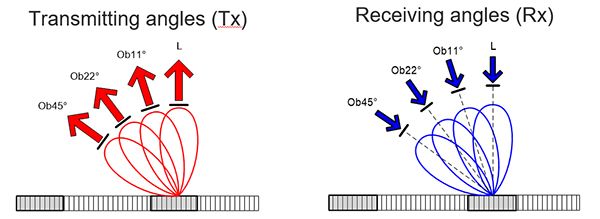

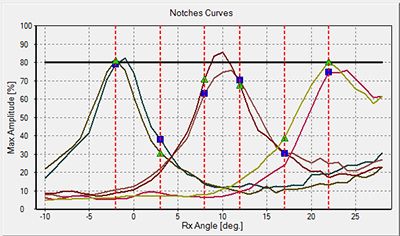

The gapless inspection solution provided by the Olympus Rotating Tube Inspection System (RTIS) manages to overcome the hurdle of calibrating for flaw detection without a reference notch for each oblique orientation. The gapless method uses only one transmitting angle for a range of oblique reference notches but covers the target area completely with a higher number of receiving channels.

Calibration targets for each receiving channel are automatically updated when setup parameters change, so the calibration sequence and the results displayed remain unchanged compared to existing discrete oblique inspection using phased array.

Results

Conclusion/Key Benefits

Because the gapless solution offered by the Olympus RTIS is just as simple to perform as the current calibration method, even medium-skilled operators can do it. It is systematized, automated, and repeatable.

Olympus’ proven QuickScan™ LT hardware already has the capability to perform gapless inspection, so existing systems can be easily upgraded to this new technology. Users can also choose whether or not to activate the gapless function, according to the strictness and precision level required for a particular pipe batch.