Stress corrosion cracking (SCC) in critical equipment can lead to a failure causing serious damage to the environment and a company’s reputation. SCC often occurs around welds, the heat-affected zone (HAZ), and into the base material in pressure vessels, process pipes, and storage tanks.

Historically, liquid penetrant testing (PT) and magnetic particle testing (MT) were the most common nondestructive testing methods used to inspect for SCC and surface-breaking cracks because they were reliable, simple, and inexpensive. However, our eddy current array (ECA) solution offers advantages over PT and MT, such as enabling users to capture and archive a digital record of their inspection and measure the depth of surface-breaking cracks.

Challenges of PT and MT

PT relies on the principle of capillary action to draw fluid into surface-breaking cracks. Inspectors have to give the liquid time to be drawn into cracks (known as dwell time). After the excess liquid is removed, a light powder is applied to highlight visible bleed out of penetrant trapped in any cracks. This step also requires dwell time.

Magnetic particle testing (MT) is used in ferromagnetic applications and has its own challenges. For example, when using wet fluorescent particles, the inspection area must be dark and additional equipment (a black light) is required.

In MT inspection, a device called a yoke is used to induce a magnetic field in the material. Colored magnetic particles are then applied to the component’s surface. These particles migrate to magnetic flux breaking from surface disruptions, creating a visible indication of a defect.

Both liquid penetrant testing and magnetic particle testing have their drawbacks, whether it’s the slow inspection speed of PT or the extra equipment required for MT. In many instances, any paint or coating must be removed from the component being tested, adding cost to the overall inspection. If the component has scale built up on the surface, it must be removed as well. Neither test method enables operators to easily measure the depth of surface-breaking cracks.

Eddy Current Testing

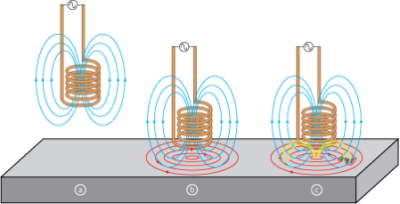

Like MT, eddy current relies on the relationship between electricity and magnetism. A flaw detector, software, and eddy current coil (probe) are used in the test. When the probe comes into contact with a conductive specimen, a circular flow of electrons (eddy currents) is induced into the part. The eddy current generates its own magnetic field, which interacts with the coil and its field through mutual inductance. Flaws in the conductive material, such as cracks, disturb the eddy current circulation. The resulting changes in impedance are displayed on the flaw detector, enabling an inspector to assess the flaw.

Benefits of Our Eddy Current Array Solution

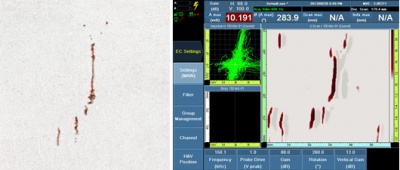

Eddy current array (ECA) uses multiple coils placed side by side in the same probe assembly. This design enables users to inspect a large area quickly. When properly calibrated, ECA is an effective method to accurately detect, size, and characterize SCC. An added benefit is that ECA enables users to digitally record inspection information, where MT/PT data are typically captured through photography.

Detection

ECA probes enable users to detect both parallel and perpendicular defects. With the right probe and configuration, users can achieve omnidirectional scanning with a high probability of detection.

Characterization

ECA enables users to assess surface-breaking cracks and, in many cases, measure the crack’s depth. When using the proper probe and calibration settings, short flaws, like SCC, can be accurately detected.

Efficiency

With ECA, users can detect defects through non-conductive paint, saving time, minimizing prep work, and reducing cost. Aside from time and waste, stripping the paint off components can potentially damage the piece and increase corrosion exposure. Since ECA is not a chemical process, no post-cleaning or chemical disposal is required.

Once the ECA flaw detector is calibrated, the inspection is nearly instantaneous, saving valuable time over PT or MT. There is no post-cleaning and parts don’t need to be demagnetized, further saving time. Because of ECA’s multiple acquisition points, data can be viewed as a C-scan, providing a more intuitive display for the inspector.

All of the setup, calibration, and scan files are easily archived, creating a comprehensive record of each inspection. Data can be quickly recalled for post-inspection reporting.

Learn more about eddy current technology and our solutions for corrosion inspection.

Get In Touch