Thanks to everyone who visited us at the 2016 ASNT Annual Conference! It’s important to support the nondestructive testing (NDT) community, which is why we were happy to host our annual ASNT reception. The reception is a place where members of the NDT community can get together, network, and talk about issues in the field or new technologies.

|

| ASNT 2016 reception, Long Beach, CA |

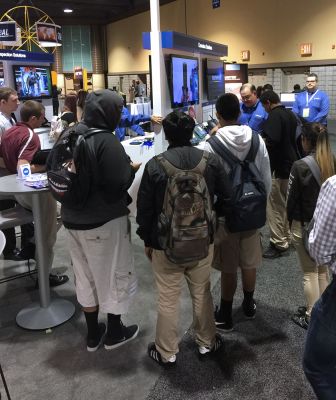

Because it’s important that the next generation understand what NDT is and what we do, we were thrilled to have the opportunity to talk with a group of high school students about nondestructive testing. We talked about the importance of NDT in helping to keep the world’s infrastructure operating safely and efficiently and discussed some of the technologies we commonly use.

|

| High school students visit our booth at ASNT to learn about NDT technology |

During the conference, our industry experts gave a series of presentations on a variety of topics for NDT professionals. If you missed any of these presentations, you can view or download them below.

Title/Speaker | Content |

Approaching a Videoscope’s Highest Physics-Limited Resolution to Improve RVISpeaker: Frank Lafleur(view presentation) | Learn about the technologies that go into making videoscope images as good as they can be, including optics, aberration corrections, image sensors, advanced processing algorithms, and light sources. |

Advances in Phased Array Weld Inspection Scan Plan Designs — Use of Compound S-scan for Improved Weld Flaw Detection and SizingSpeaker: Chris Magruder(view presentation ) | Chris highlights how compound S-scans improve on traditional phased array weld inspection by providing users with more inspection coverage of the weld volume and the heat-affected zone. |

Inspection of Complex Geometries Using Flexible Ultrasonic Phased Array ProbesSpeaker: Jeff Wells | New flexible probe materials have made it possible to use ultrasonic phased array technology to inspect parts that have complex or changing geometries, such as pipe elbows or composite parts for the aerospace industry. By conforming to changing surfaces or geometry, flexible phased array probes enable users to conduct inspections with high resolution. |

Scalable NDT Instruments for the Inspection of Variable Geometry ComponentsSpeaker: Etienne Grondin(view presentation) | As the production rates of critical parts and components in industries like aerospace have increased, so has the need to conduct ultrasonic phased array inspection quickly and efficiently. New scalable phased array inspection tools are enabling NDT integrators and manufacturers to address the challenges that they’re facing in terms of system performance, production output, and quality control. |

Advances in Handheld XRF-Based Alloy PMI/Material TestingSpeaker: Alex Thurston(view presentation) | Recent technological advances in handheld X-ray fluorescence (HHXRF) analyzers are enabling users in positive material identification (PMI) and material testing applications to maximize their uptime. Computational improvements now position HHXRF in an analytical range that rivals aspects of laboratory-grade XRF analysis while maintaining portability. |

XRF Advancements Improve Detection of Trace Silicon in Carbon Steel in On-Line, High-Temperature Process Piping and ComponentsSpeaker: Michael Hull(view presentation) | Carbon steels with a low silicon content (< 0.10%) can corrode at an accelerated rate when exposed to sulfidation corrosion conditions. Handheld X-ray fluorescence (XRF) analyzers are important tools for quantifying the levels of silicon as it pertains to API RP 939-C. Improved analyzer hardware and software bring a new level of speed, improved accuracy, and precision to the detection of silicon at concentrations below 0.10 wt % in carbon steel process piping systems and components up to 900 °F. Specifically, better detector/signal processing produces improved sensitivity and enables reduced test times in high-temperature environments. |

Eddy Current Array Inspection of Carbon Steel Welds with Dynamic Lift-Off Compensation and Depth SizingSpeaker: Tommy Bourgelas(view presentation) | The use of eddy current array (ECA) technology increases the speed and reliability of surface inspections. However, surface inspection of carbon steel welds is challenging due to the geometric shape of the weld crown, paint thickness, the presence of crests and crowns, and the ferromagnetism of the carbon steel. Combining an orthogonal-type ECA probe with dynamic lift-off compensation and depth sizing tools results in a solution that can potentially replace magnetic particle inspection for carbon steel weld inspection. |

Getting More Precision in Videoscope Measurements, While Taking Larger Measurements from Farther AwaySpeaker: Charles Janecka (view presentation) | The stereo measurement capability of remote visual inspection videoscopes is important for determining the size of flaws, indications, or areas of interest. Recent advances have improved the precision of stereo measurement compared to what existed a decade ago. Learn more about what goes into the hardware and software that translates into more precise measurements. |

.jpg?rev=1A35)