Contexte

Les frottements entre pièces métalliques mobiles génèrent de la chaleur et accélèrent l’usure. Ces frottements dépendent fortement de la rugosité des surfaces de contact. Si les surfaces sont très rugueuses avec de grandes crêtes et vallées, les pièces ne se déplacent pas de manière fluide et peuvent même se bloquer. À l’inverse, en l’absence de toute rugosité sur l’une des deux surfaces de contact, celles-ci peuvent fusionner ensemble. Afin que les pièces métalliques mobiles se déplacent correctement, il faut que la rugosité de surface soit adaptée. Classiquement, les industriels mesurent la rugosité de surface à l’aide de jauges de rugosité à contact par déplacement d’un stylet sur les surfaces métalliques. Cette méthode est limitée par l’épaisseur du stylet et ne permet pas d’effectuer des mesures de rugosité précises.

Les solutions d’Olympus

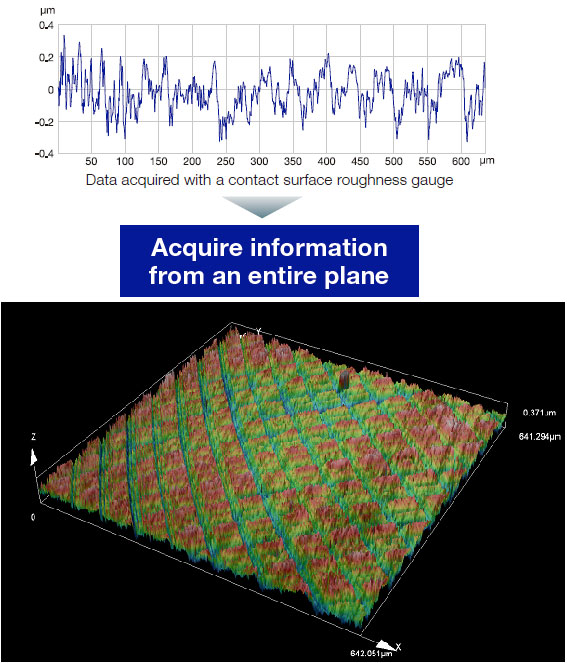

Le microscope de mesure laser 3D LEXT d’Olympus dispose d’une jauge de rugosité de surface sans contact qui, contrairement aux instruments à stylet, vous permet d’effectuer des mesures planaires avec une résolution de 10 nanomètres. Ce niveau de précision dépasse celui proposé par les jauges à contact conventionnelles et assure que les mesures de rugosité sont aussi précises que possible. Grâce au laser du microscope LEXT, toutes les irrégularités de surfaces peuvent être entièrement mesurées, mêmes les plus petites et celles ayant des configurations complexes et des angles abrupts (Figure 1).

Caractéristiques du microscope

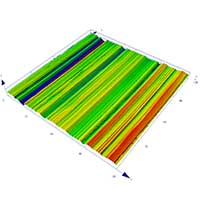

Le microscope LEXT effectue des observations 3D avec des mesures de très haute résolution et une densité de pixels élevée (Figure 2). La technologie de mesure de la rugosité de surface sans contact permet de mesurer des irrégularités à géométrie très fine que les jauges à contact conventionnelles sont incapables de détecter. Le microscope LEXT se démarque par une sensibilité d’inclinaison élevée, laquelle permet de mesurer avec précision des irrégularités complexes et très inclinées.

Figure 1 : Comparaison des mesures de rugosité faites à l’aide d’un stylet à contact (en haut) et à l'aide du stylet laser du microscope LEXT (en bas)

Image

Figure 2 : Rendu 3D de la rugosité de surface produit par le microscope LEXT