Introduction & Background:The use of Field Portable X-Ray Fluorescence (FPXRF) & X-Ray Diffraction (FPXRD) within the Mining & Mineral Exploration Industry is fast becoming an established method for conducting real-time geochemical investigations in the field, with the significant benefit of receiving a determination at the actual sample location. Customized analyzer configuration and flexibility across the element calibration suite, from Mg (z=12) to U (z=92), provides versatility to the Explorer or Miner looking for phosphate as well as accompanying geochemical pathfinder signature elements. |  |

Phosphate & FPXRFDue to the high concentration of phosphate (> 15-20% P2 O5) required to constitute an economic deposit, the DELTA represents an effective tool for use in both exploration and mine grade control. The lower Limits of Detection (LODs) for phosphorus with the new generation silicon drift detector (SDD) XR F analyzers is in the order of 0.05% (500 ppm), dependent on sample matrix. Obviously, this LOD is significantly higher than for most of the transition metals because Phosphorus is a much weaker responder to X-Ray radiation. This is due to the low energy emission lines required to excite the fluorescence of phosphorous at only 2.01KeV for the K-Alpha line and 2.14 for the K-Beta line. As such the determination of phosphorous relies upon using lower voltage and filtering settings (Beam settings), over longer test times (60-120 secs versus 10-20 secs) to obtain good levels of precision. The use of new silicon drift detector (SDD) technology, which combines dramatically increased count rates, lower background, and higher resolution, can significantly reduce analysis time and enhance results. |

|

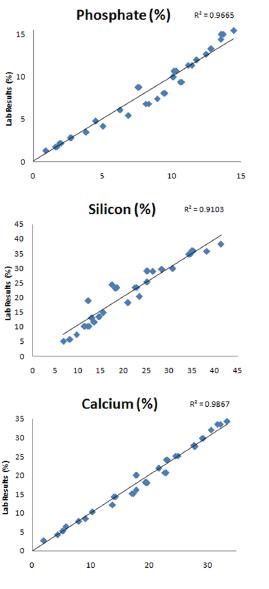

Light Element Analysis & Sample PreparationIn FPXRF analysis, light elements (LE ) are generally regarded as those with Atomic number (Z) less than 18 (Argon) and usually refer to the group: Mg, Al, Si, P, S & Cl. The investigation of Iron Ore deposits are dominated by this LE suite, particularly Al, Si, P, S & Ca and the mineralization style is often hosted in a coarsely granular and crystalline matrix. Therefore, they are also significantly influenced by high sample heterogeneity and in order to achieve meaningful (decision level) analytical quality, it may be necessary to undertake some form of sample preparation. This can involve a coarse crush, and if necessary pulverizing the sample to < 200 um and then placing into an XRF sample cup using Polypropylene film supports (as opposed to Mylar film which cannot be used for looking at LE ). Why Use FPXRF?The aspect of "True Portability" with the latest generation of XRF essentially enables the ability to bring a "miniaturized version of the laboratory" into the field, with obvious limitations. We are clear and transparent about these limitations: (1) Higher LOD's than lab-based techniques (2) Lower precision than lab-based techniques (higher +/- values but no compromise on accuracy above LOD's (3) Less repeatable results. FPXRF should not to be seen as a replacement for the laboratory and should be used in conjunction with laboratory and industry standard reporting protocols such as determined by the ASX (JORC CODE) & the TSX (43-101). The main advantage of FPXRF lies in the ability to generate, dynamic, real-time, spatially registered geochemical data sets, rapidly. The Geoscientist can now immediately postulate the elemental characteristics of the observed regolith or lithology dynamically, making informed decisions while still in the field, at the exact location of the sample of interest. Instant and interactive approaches to exploration project management, target delineation and associated vectoring towards mineralization are now possible. This results in significantly reduced time-frames with less time intensive reiterations, such as the excavating samples & sending them to the lab with the associated "normal" lengthy turnaround times and lags. FPXRF can be thought of as being a pre-screening tool used to select the best and most appropriate sample to submit to the laboratory for comprehensive and more detailed analysis. Additionally, the ability to refine your sampling program in the field real-time means that you can easily increase sample density & resolution instantaneously. These field based efficiency gains are advancing project time-frames and assisting companies to better utilize their time in the field and maximize the exploration budget. |  Phosphate, Silicon and Calcium Performance on a typical Phosphate Rock. (90 sec test time in AIR using Mining Mode on a DELTA SDD Analyzer)  |

LOD's: The Million Dollar Question

The determination of the analytical Limit Of Detection (LO D's) depends on many aspects, often not directly related to the instrumentation of choice. Some of these influences include (influential factor denoted in brackets):

- The energy of excitation or X-Ray source (instrument) Note: This is not all about obtaining the maximum voltage (or keV). It is reliant on the process of fine-tuning both the X-Ray voltage and current to maximize the received count rate and therefore analytical precision (instrument)

- The atomic number and associated response of element(s) being analyzed (sample)

- Concentration of Elements present (sample)

- Relative density & matrix composition (sample)

- Sample size, granularity & surface geometry (sample & user)

- Length of test run (user)

- The quality of the instrument calibration & QC samples used to "tweak" the instrument (user & instrument)

"AS SUCH, THE SAMPLE IS THE MOST INFLUENTIAL FACTOR WITH REGARDS TO DETERMINING LOD's WHEN USING FPXRF"