The DELTA Line Medical Device Component InspectionChallengeThere is no more challenging or regulated use of alloy materials than implants for the human body. Implantation alloys are selected based on a combination of characteristics including immunity to corrosion, bio-compatibility, strength, low modulus and density, and the capacity for joining with bone and other tissue. As biomaterial science evolves, new and novel metal alloys are being used for critical applications. Small changes in the concentrations of constituent elements or impurities can be critical as they may alter strength-to-weight ratio and corrosion resistance. As such, thorough quality control testing is necessary. Medical device manufacturers require easy-to-use, accurate and precise analytical techniques to keep up with progress and provide on-the-fly material identification as part of the overall documentation and compliance process. |  |

Material compliance technology must be cost-effective while not extending any time-to-market for product. The compliance technique should also be able to acquire required information, such as alloy identification and composition, without destroying or affecting the product in any way. And procedures must be maintained and executed for identifying each unit, lot, or batch of finished devices and components, all documented in the Device History Record (DHR).

Solution

With its precision, accuracy, advanced electronics and data logging capabilities, the DELTA provides a solution for this critical alloy material verification.

The DELTA handheld XRF is ideal for fast verification of metal alloys used in the Medical Device Industry. All analyses are completely non-destructive. The DELTA provides alloy composition chemistry (up to 30 elements simultaneously) and grade identification within seconds. The user interface also provides an instant comparison of analysis results to engineering grade specifications, identifying "out of spec" elements and tramp constituents. Up to 100,000 readings, including sample identification information and spectra, can be stored and preserved for data integrity as part of the DHR (§820.72). |  |

The DELTA offers excellent Limits of Detection (LOD's) and light element analysis as a result of its unique 4W, 200µA (max) x-ray tube, state-of-the-art electronics, Silicon Drift Detector, floating point processor, and redesigned analytical geometry. All this in a durable and industrialized, handy analyzer weighing in at just 3.25 lbs.

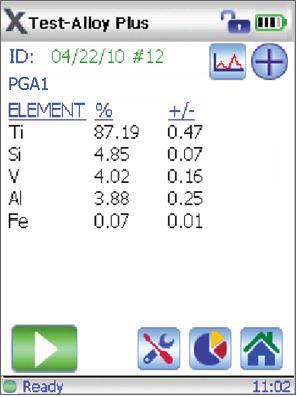

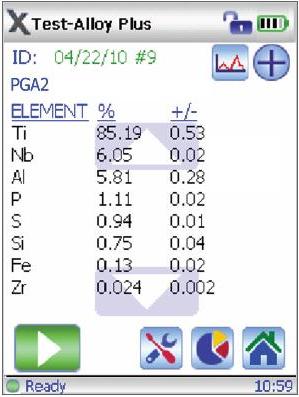

DELTA Results:Analysis results from a DELTA analyzer are shown below. Screenshots from the direct analyses of two different proprietary implantation alloys, labeled PGA1 and PGA2, are shown. These samples were analyzed directly, without preparation or modification. (XRF analysis is completely non-destructive.) Analysis times were 20 seconds in duration, for the sake of composition analysis precision. (Quick sorting and alloy identification can be achieved in as little as 1-2 seconds. Longer analysis times can be used for chemistry monitoring. For example, Fe, a strictly regulated constituent in Co alloys, can be closely measured at low concentrations to ensure compositional compliance.) Results can be quickly exported to a database for archiving. The DELTA Reporting Software can instantaneously produce formal analysis reports, or the DELTA analyzer can send results directly to a wireless printer for instant documentation. |  |

|  |

| DELTA Screenshot: Analysis result of sample PGA1 | DELTA Screenshot: Analysis result of sample PGA2 |