Engrenage automobile

Inspection de la rugosité de surface des dentures d’engrenage des moteurs électriques

Ces dernières années, la réglementation visant à réduire les émissions des voitures est devenue une tendance mondiale. Par conséquent, la fabrication et la vente de voitures prétendument « écologiques », comme les voitures électriques, hybrides et hybrides rechargeables, se multiplient rapidement. La définition des voitures écologiques varie d’un pays à l’autre. Certains ne reconnaissent pas les véhicules hybrides comme des voitures écologiques, mais nous les incluons ici.

Les voitures écologiques rejettent moins de CO2, voire aucune émission de CO2, par rapport aux véhicules essence. Elles sont aussi silencieuses avec une pollution sonore minimale. Les véhicules essence ont également tendance à être bruyantes en raison des mouvements des pièces du moteur, comme le va-et-vient des pistons dans les cylindres.

Les moteurs électriques quant à eux tournent, ce qui rend les voitures écologiques beaucoup plus silencieuses que les voitures essence. Même si ce silence peut être peut parfois représenter un danger pour les piétons, il est généralement perçu comme une amélioration. Toutefois, certains composants des voitures écologiques peuvent augmenter leur niveau sonore; par exemple, c'est le cas de l’engrenage, si les surfaces de la denture ne sont pas assez lisses. Pour cette raison, les exigences relatives à la rugosité de surface de la denture des engrenages utilisés dans les voitures écologiques sont fréquemment plus strictes. Les outils utilisés pour valider la rugosité de surface de cette denture doivent offrir une grande précision pour répondre à ces exigences. En outre, les appareils de mesure à contact, comme les systèmes à stylet, risquent d’endommager la surface des engrenages lors de la mesure.

La solution d’Olympus : mesure de la rugosité à l’aide du microscope OLS5000

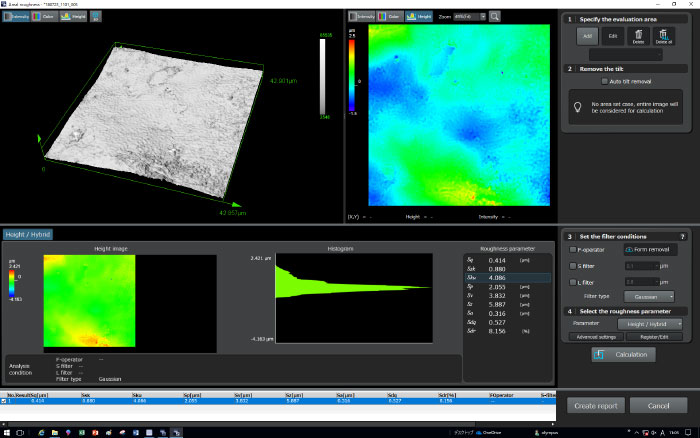

Le microscope à balayage laser 3D LEXT OLS5000 sans contact permet de mesurer la rugosité de surface des dentures d’engrenage avec une grande précision :

(1) La surface est balayée au moyen d’un faisceau laser de 0,4 µm de diamètre afin d’acquérir des données très précises, ce qui permet des mesures de rugosité mêmes pour les dentures les plus petites difficiles à mesurer à l’aide de jauges à stylet.

(2) Étant donné que les données de rugosité acquises par les microscopes laser planaires (et pas simplement linéaires), il est possible d’obtenir simultanément des images en couleur et laser ainsi que des données de profil 3D, ce qui offre une analyse bien plus approfondie qu’avec un système à stylet.

(3) Le microscope OLS5000 est doté d’une fonctionnalité d’assemblage horizontal de différents types de données, ce qui vous permet de mesurer rapidement un champ de vision plus large avec une grande exactitude.

Images

Exemple de mesure de la rugosité de surface de denture d’engrenage

(réplique : lentille d’objectif 100X, zoom optique 3X)