Removing Paint is Time Consuming and Expensive

For decades, legacy NDT methods, such as penetrant and magnetic particle inspection, required that paint be removed from parts before they could be inspected. The paint was often removed using harsh chemicals. Over time, increasingly strict government regulations about chemical safety and waste treatment have caused the cost of paint removal to rise dramatically. As the cost of paint removal increases so does the overall cost of inspection.

Inspect Through Paint with Dynamic Lift-Off Compensation Technology

The use of a flexible PCB probe with cross-wound coil technology combined with dynamic lift-off compensation makes it possible to detect surface-breaking cracks through paint, resulting in significant time and cost savings.

|

| The principle of dynamic lift-off compensation. |

Our MagnaFORM™ probe features dynamic lift-off compensation and helps make weld inspection fast and efficient. The dynamic lift-off compensation helps the probe maintain sensitivity to surface-breaking cracks. All of the channels perform lift-off compensation in real time. Now, we can inspect through paint up to 3 mm thick.

|

| The MagnaFORM probe. |

|

| The MagnaFORM probe enables you to inspect through painted surfaces. |

The MagnaFORM Probe Delivers Results

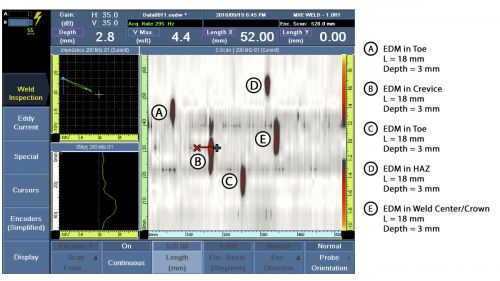

The example below demonstrates that the MagnaFORM probe provides you with clear images through paint for indications with the same lengths and same depths located on different areas of welded parts. The amplitude of the signals is the same for each location, demonstrating consistent defect detection in all locations.

|

| A C-scan image using a MagnaFORM probe of EDM notch indications at different locations. |

Don't spend valuable resources on stripping and repainting surfaces as part of your inspection process. With eddy current array technology and the advanced features of the MagnaFORM probe, you can inspect welds and surfaces through paint, helping you save time and reduce cost. To learn more, check out this video about the MagnaFORM solution.

Get In Touch

.jpg?rev=FF00)