Where Vanta™ XRF analyzers are used for material or grade identification—in metal processing or fabrication, for example—barcodes can be used to track a batch, lot, or serial number. To make this traceability more accessible and convenient, Vanta analyzers can read barcodes and record the data directly.

How to Use the Vanta XRF Analyzer’s Barcode Scanning Feature

You can scan barcodes with the Vanta analyzer’s panoramic camera and record that information into a test note field. This feature is available on any Vanta analyzer that is equipped with a panoramic camera.

Before you can begin using the barcode scan feature, you need to create a notes template with the “barcode” note-field type on your PC and deploy it to the Vanta analyzer. Creating a customized notes template can be done in the fleet manager portion of the Vanta PC software. For more details, check out these instructional videos on using the fleet manager and creating a notes template.

Here are the configuration steps that are specifically related to the barcode scanning function:

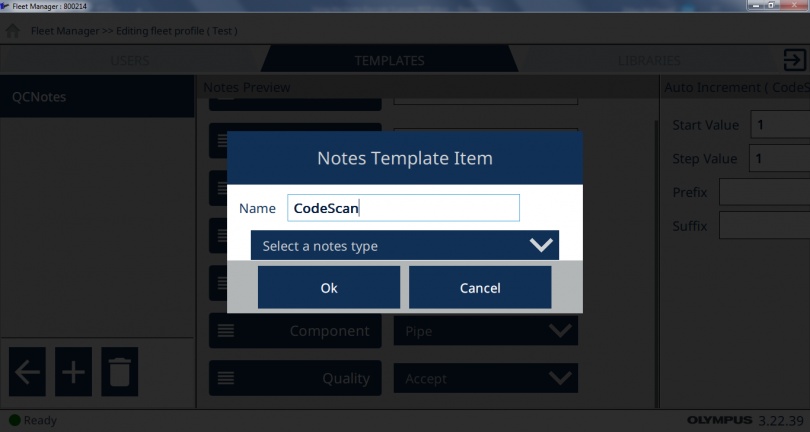

- When editing the notes template in the Vanta PC software’s fleet manager, click the add note field button to add a barcode scanner-useable field.

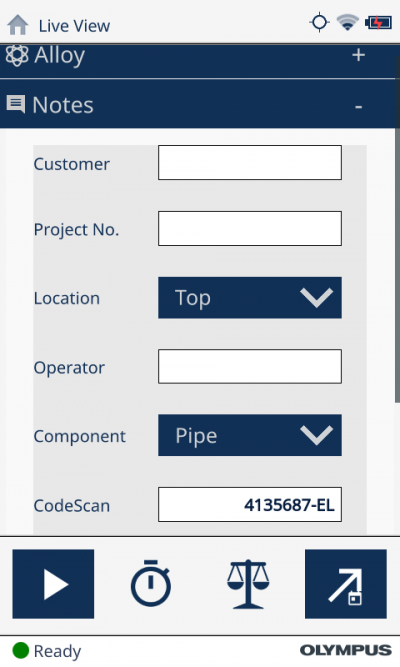

- Type in a name for the field (such as “CodeScan,” for example), select the option for “barcode,” and then press OK to add the field to your notes template.

- You can now exit the fleet profile and deploy the notes template to your analyzer to begin using it.

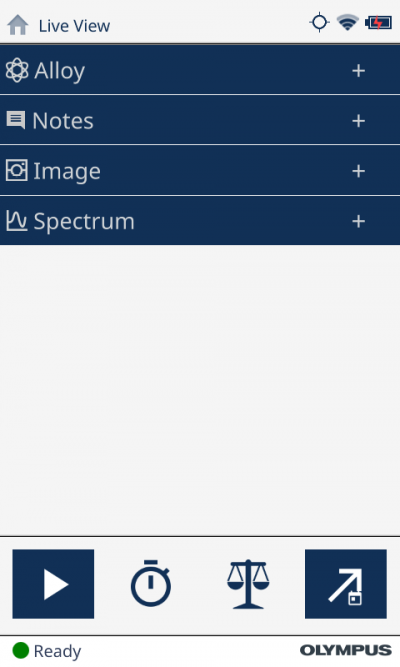

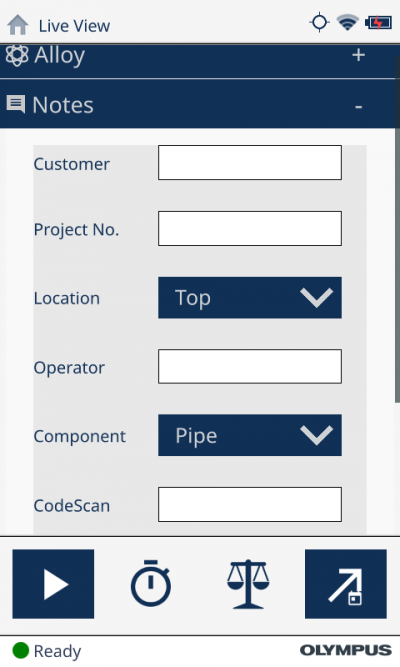

- On your Vanta XRF analyzer, select the template you just created. On the main test screen, you can expand the Notes pane by pressing the plus icon. The barcode scanning field should appear in the new template with the name you gave it (see the “CodeScan” field in the example below).

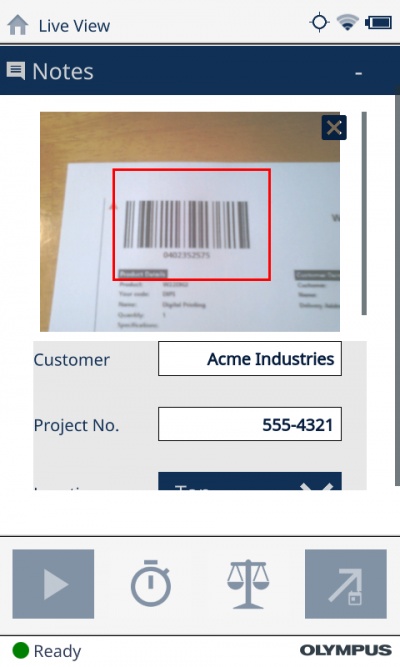

- Tap once in the barcode field to bring up the macro camera image and scan marker, which is the red rectangle in the image. Be sure to only do a single tap when selecting the field.

- To scan a barcode, simply align the code in the red scan marker box. While the camera autofocuses the image, you may need to move the analyzer's nose back and forth to properly align the barcode within the red box on the screen.

- After the instrument has read the barcode, it will populate the field with the code’s data and beep. You can then resume testing as normal.

This procedure was done using optional notes entry, but it also works in much the same way with forced notes entry—simply tap the barcode note field to bring up the camera image and scan marker.

Editing and Rescanning the Barcode Reading Data

Barcode fields can also be manually edited, and text can be entered into them much like fixed test fields. Simply close the scan image by pressing the “x” icon to bring up the onscreen keyboard to manually enter text. You can also bring up the keyboard by double tapping the field as opposed to a single tap.

If you would like to rescan a code into a field, exit the barcode field by selecting any other note field in the template, then reselect the barcode field with a single tap to bring back up the scanning image. Be aware that rescanning will overwrite the previous barcode reading data.

Up Your Quality Control Game with a 2-for-1 Material ID and Traceability Tool

That’s all there is to it! You are now ready to use the Vanta analyzer’s barcode scanner for rapid notes entry. Stay tuned for future updates that will combine this onboard barcode scanner capability with our Olympus Scientific Cloud™ services in new and exciting ways to improve productivity and product tracking.

If you want to learn more, watch this short video to learn the value of integrating barcodes into your organization’s processes to streamline XRF testing.

Related Content

Access a Better Way of Working—Experience Olympus Scientific Cloud 3.0

Infographic: 5 Benefits of Cloud Connected Results with Vanta Handheld XRF

Share XRF Results Across the Globe with the Vanta™ Data Viewer

Get In Touch