A microscope is a versatile tool used to magnify and image a range of objects with details too small to be seen by the naked eye. While the microscope is often associated with life science, it plays a critical role in industrial inspections.

Consider component cleanliness inspections, where manufactured components or fluids must meet high quality standards for contamination control. Manufacturing processes can potentially add debris, dirt, or fibers on each component. Unless carefully controlled, microscopic residue on components can impact the final device’s performance or safety.

Imaging these tiny particles and fibers with a microscope-based system enables inspectors to obtain a range of visual information about the contaminants for cleanliness standards. This post outlines four ways a picture (captured using a microscope) is worth a thousand words in component cleanliness inspections.

1. Obtain exact particle counts.

An exact particle count represents the level of existing contaminants on different samples quantitatively. This information can be useful, for example, if you are optimizing your manufacturing procedure to reduce contaminants. Simply refer to the number of contaminants to see how well your optimization worked.

Also, depending on the standard used for your inspection and the filter tested, the measured number of particles needs to be normalized according to a reference value. This again gives a comparison value, which enables you to compare multiple measurements, even if the examined samples are not the same size.

Microscope systems that count the particles on every frame provide an exact particle count. Microscope images also show the composition, shape, and color of every particle. This enables you to verify the automated results by looking at the images. Seeing all the morphological features of particles makes it possible to distinguish between particles and fibers, as well as metallic and nonmetallic particles.

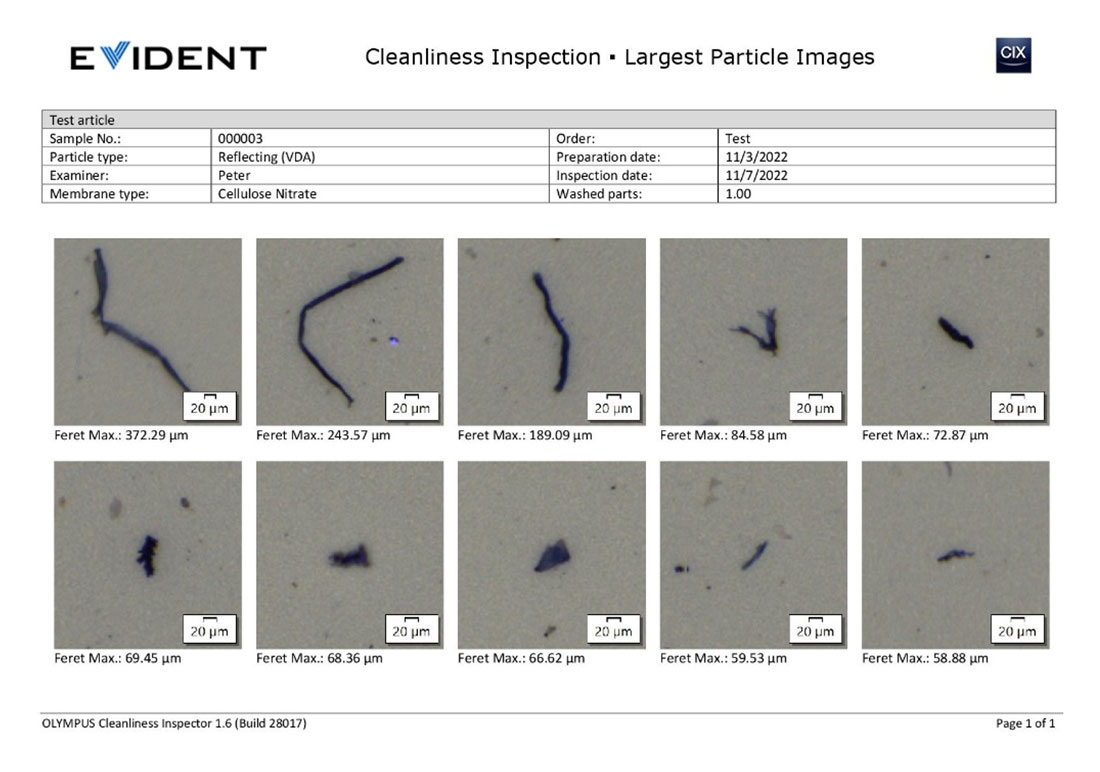

Microscope images of particles captured using the OLYMPUS CIX100 technical cleanliness inspection system.

2. Verify particle types.

Metallic particles are harder than nonmetallic particles, making them potentially more harmful to the components being tested. As metallic particles have a shine that gives them high reflectivity, some systems can automate the detection of reflecting and non-reflecting particles with a single scan. However, visual verification is important to check the results.

Microscope systems that show the actual color of particles enable you to confirm if a particle is metallic by showing details such as the metallic shine typical of certain metals. Learn how this works by reading our post, See Particle Contamination in Real Color to Verify Metallic Particles.

Particles shown in their actual color on the CIX100 technical cleanliness inspection system.

3. Determine the source of contaminants.

Detailed images of particles can also help you determine the source of contaminants.

For instance, the color of a fiber could match the color of a technician’s clothing or the cleaning cloths used at the facility. Another example: dull edges on a steel particle found in oil could indicate it has traveled around the system several times.

Microscope imaging of particles gives you visual evidence to figure out the root cause of critical problems and take timely countermeasures.

Detailed image of a particle captured using the CIX100 technical cleanliness inspection system.

4. Produce easy-to-understand reports.

Text-based reports are understood best by the technicians who carried out the inspections. However, management, finance professionals, and other decision-makers can more easily understand image-based reports.

A system that supports both kind of reports is the most efficient, especially when it includes templates for standard reporting as requested by international and national directives.

Part of a cleanliness inspection report showing microscope images of particles and fibers. Reports from the CIX100 technical cleanliness inspection system include both text and images so the results are easy to understand.

Perform Timely Cleanliness Inspections Using a Turnkey System

While microscope analysis has many benefits for component cleanliness inspections, not all microscope systems are built the same. A turnkey solution such as the CIX100 system supports your cleanliness inspection from beginning to end with high reproducibility, a fast inspection workflow, and an intuitive user interface for operators of all skill levels.

Related Content

Perform an Efficient Cleanliness Analysis with 3 Added Capabilities

Oil Contamination and Analysis—Expert Insights on an Invisible Problem

See Particle Contamination in Real Color to Verify Metallic Particles

Get In Touch