The OLYMPUS CIX100 system is a turnkey solution dedicated to technical cleanliness inspection and analysis of manufactured components and parts. The system’s hardware and software are optimized to take you seamlessly through the cleanliness analysis process from sample preparation to reporting.

In previous posts, we’ve reviewed how the system provides reliable and repeatable results for company and industry standards, delivers a fast inspection workflow, and offers an intuitive user interface for operators of all skill levels. Our engineers continue to release new software updates to further streamline the cleanliness analysis process.

Here are three added features in CIX™ software version 1.5.2 to make your cleanliness analysis even more efficient:

1. Directly review multiple samples after a batch scan.

To reduce inspection time in routine applications, the multi-sample scan now includes a mode where you can directly review the inspection results of all the scanned samples. First, the scan runs with the same inspection configurations and usually identical settings for all samples, saving time. Optionally, individual settings can be defined for each sample. After the multi-sample scan, you can review and revise individual detected particles on each sample.

Multi-sample scan

2. Automatically adjust the inspection area to different membrane sizes.

The default sample in the OLYMPUS CIX100 system is a filter membrane with a diameter of 47 mm. Dedicated sample holders are also available for membranes with diameters of 25 mm and 55 mm. The software now includes inspection area presets tailored to the visible sections of different membrane sizes enabling you to automatically adjust the scan size with the click of a button. This saves time since there is no need to find the center position on the sample and adapt the inspection area manually.

Easily perform cleanliness analysis with different membrane sizes on the OLYMPUS CIX100 system

Adjust the inspection area to fit different membrane sizes with the click of a button

3. Inspect rectangular areas.

The OLYMPUS CIX100 system is optimized for inspecting circular filter membranes. With software version 1.5.2, the system can now apply rectangular inspection areas. The option to inspect rectangular areas increases the versatility of the system for various cleanliness standards.

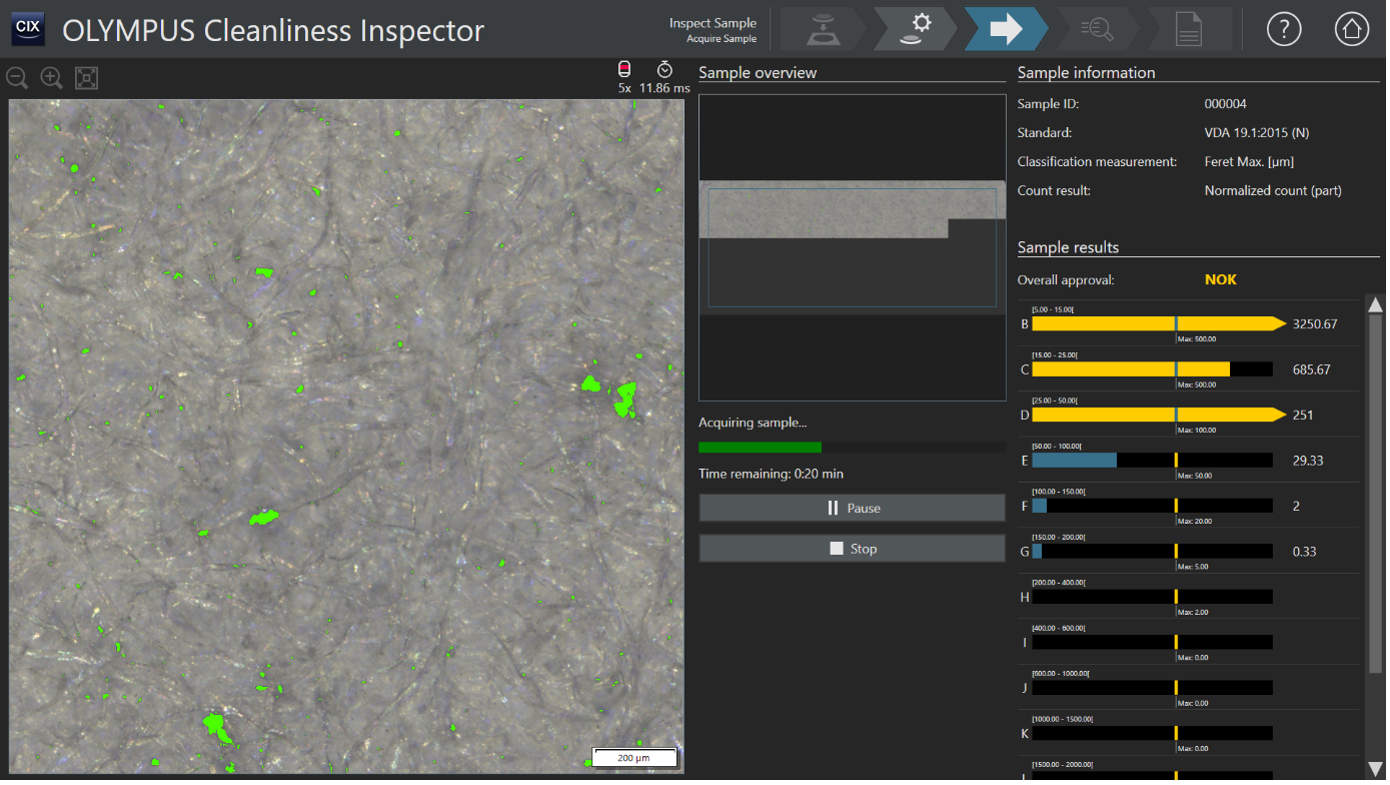

The software acquires a rectangular inspection area

Particle analysis of the sample after acquiring the rectangular inspection area

Related Content

An Introduction to Technical Cleanliness Inspection

7 Capabilities That Make Technical Cleanliness Inspections Easy for Novice Operators

Video: Overview of the OLYMPUS CIX100 Cleanliness Inspection System

Get In Touch