Our full range of NDT ultrasonic testing (UT) equipment provides outstanding capabilities to nondestructively measure thickness, locate defects, and test the structural integrity of a material or component:

- UT thickness gauges can measure thickness in most engineering materials

- Ultrasonic/phased array flaw detectors can locate and size hidden cracks, voids, disbonds, and similar discontinuities in a wide range of materials

These ultrasonic testing instruments are used in many applications across the aerospace, automotive, railway, mining, and oil and gas industries.

Listed in alphabetical order, here are the various applications you can perform using ultrasonic testing:

Aluminum

Aluminum cans used in the beverage industry are routinely inspected for wall thickness accuracy. With ultrasonic gauging, you can measure wall thickness instantly and digitally by simply coupling ultrasound into the part from the outside.

Austenitic (and Other Alloys)

Austenitic materials account for 70% of all commercially produced stainless steel, which is primarily due to its good resistance to corrosion. Corrosion resistant alloys (CRAs) and Babbitt metals fit into this material group. Ultrasonic testing is helpful when inspecting:

- Thick wall, thick components

- Thick, dissimilar welds

- Thin-walled austenitic steel inspection of pipes, where standard linear shear-wave inspection is impossible

Carbon Steel

Structures made of carbon steel are subject to corrosion that reduces the original thickness of the material. If undetected over time, corrosion will weaken walls and can cause dangerous structural failures. Both safety and economic considerations require that metal pipes, tanks, or structures that are susceptible to corrosion are inspected regularly.

Ultrasonic testing enables you to accurately detect potential internal corrosion without damaging the material and while accessing one side of the surface, even through paint and at hot temperatures (while in service). Axial inspection of metal pipes is another possibility using our ultrasonic testing equipment and scanners.

Along with corrosion measurement involving metal pipes and tanks, precision thickness measurement during the manufacturing process is another application. One example is the measurement of wall thickness of hollow turbine blades for aircraft engines, both to detect core shift during manufacturing and to gauge wear in service.

Inspection of welds on pipes and other tube geometry is also a challenge that ultrasonic testing equipment, such as an NDT industrial scanner, can meet both acoustically and mechanically.

Castings

Wall thickness of hollow ferrous and nonferrous castings can be measured ultrasonically, even those with complex shapes like engine blocks. Ultrasonic gauges can also be used to check nodularity in cast iron.

Voids, porosity, inclusions, and cracks in the metal can occur during the casting process. These conditions produce ultrasonic indications that can be identified by a trained operator using an ultrasonic flaw detector with the appropriate transducers.

Additive manufacturing, which is expanding rapidly in the composites industry, is also used for castings.

Ceramics

Most structural and electronic ceramic components are well suited for ultrasonic thickness gauging. Fired ceramics can generally be measured over a wide thickness range and with a great degree of precision. Ultrasonic gauges can be used to measure the thickness of structural ceramic products, such as turbine blades, valves, and other engine components. Elastic modulus can also be calculated through measurement of longitudinal and shear wave velocities.

Clad Metal Cookware

Conventional ultrasonic testing enables the monitoring of thickness of clad metal cookware, which incorporates a stainless steel body with a base made from a relatively thick core of either copper or aluminum sandwiched between two thin layers of steel. This is important for quality control, as manufacturers of clad cookware need to monitor the thickness of the three layers comprising the base.

Composites

Composites are often stronger and lighter than conventional materials (such as aluminum, steel, or even titanium). Ultrasound enables detection of inner and outer skin disbonds, presence of fluids, and crushed cores.

The increasing use of aircraft with composite structure has created the need to quickly check for impact damage at the airport during plane turnaround, for example. Phased array ultrasound can be used for full volumetric inspection of complex aerospace composite parts. Also, ultrasonic thickness measurements of aerospace composites can be made instantly on parts such as wings, fuselage, ducts, panels, and fan blades.

Materials that fit into this category include carbon fiber (CFRP) and glass fiber (GFRP).

Fiberglass

Ultrasonic thickness gauges can be used for various fiberglass applications by measuring parts from one side. Fiberglass storage tanks and pipes, for example, can be checked as part of the manufacturing process and while in service to help ensure that no erosion or delamination from corrosive chemicals has occurred. Thickness gauging of fiberglass boat hulls and the measurement of fiberglass gelcoats are also known uses of ultrasound in the boating industry.

Glass

Glass is an inexpensive and highly versatile engineering material that can be cast, molded, or blown into a wide variety of shapes. It’s also highly transmissive to high-frequency sound waves, making it an excellent material for ultrasonic thickness gauging.

The geometry of most common glass products makes mechanical thickness measurement with calipers or micrometers difficult or impossible. However, virtually all common glass products can be easily measured with ultrasonic thickness gauges. Testing doesn’t damage the glass, and thickness measurements are instant, accurate, and reliable.

Gold

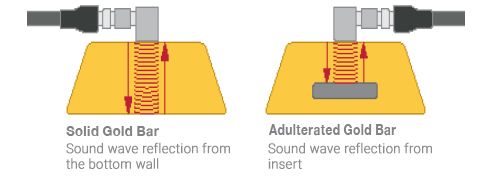

Ultrasonic flaw detectors can also help ensure a gold bullion bar is homogeneous and free of insertions.

The sound waves from the flaw detector will reflect from the bottom of the gold bar, an insertion within the gold bar (e.g., a tungsten metal insertion), or an internal void. You can use a flaw detector to distinguish between the waves reflecting from the bottom of the gold bar and waves reflecting from insertions or internal voids.

Iron

Ultrasonic testing equipment can be used to measure the degree of nodularity in cast iron or distinguish nodular iron from gray iron. This technology is helpful for foundries that need to check nodular iron for uniformity.

Liquid

If you need fast, automatic measurement of the liquid levels in a large number of containers going through a filling process, ultrasonic liquid level measurement is a good solution. Ultrasonic testing can measure liquid levels in a container or pipe using a noninvasive method (direct level measurement) or detect the presence or absence of liquid in a sealed container (presence/absence test).

Mining Equipment

In the mining industry, phased array ultrasonics offers many benefits to heavy equipment component inspections, such as:

- Thick wall lug and bore inspections

- Gear inspections inside mining equipment

- Inspection of an excavator’s swing shaft component

Plastic

All common plastics can be measured ultrasonically. Examples include:

- Multilayer packaging used for food products and beverages

- Automotive air bag cover tear seams

- Fuel tanks

- Polymer aircraft windshields

Also fitting into this material category is high-density polyethylene (HDPE), a versatile thermoplastic used in piping and many other fabricated parts and components.

Rubber

Sound attenuation in rubber is typically high in comparison to other materials, but thickness can usually be measured with high-penetration gauges.

Common applications include:

- Wall thickness of rubber tubing

- Total thickness and depth of reinforcement in rubber conveyor belts

- Tread thickness in tires

Titanium

Some aircrafts structural parts, such as the engine mount and frame, are built with titanium casting. This material is very difficult to inspect because of its large grain structure. Using ultrasound phased arrays to inspect titanium castings offers much better detectability than conventional methods using X-ray or ultrasound technology.

Explore Additional Ultrasonic Testing Applications

There are many ultrasonic testing applications across industries, and we will continue to discover more! Browse our Online Resource Center to explore even more applications or subscribe to the InSight blog to be first to hear about new applications and case studies.

Related Content

E-Book: Introduction to Phased Array Ultrasonic Technology Applications

Webinar: Advances in Ultrasonic and Phased Array Methods of Corrosion Detection and Assessment

Get In Touch

.jpg?rev=DF75)