To continue our series on sampling techniques in technical cleanliness inspections, this post will focus on a sampling method that is commonly used to analyze fluid: direct liquid filtration. Simply put, direct liquid filtration is a sampling technique used to determine the particles present in a liquid.

In direct liquid filtration, the liquid with suspended particles is filtered through a membrane filter so the particles collect on its surface. Then the filter membrane is imaged with a light microscope for particle analysis. Keep reading to learn more about this fluid sampling method, including best practices to follow when extracting a fluid sample for cleanliness analysis.

Small Particles, Great Effects: The Importance of Clean Fluids in Machinery

Shipping, energy, offshore, and pharmaceuticals are some of the industries that have discovered the benefits of clean fluids.

Milling machine using oil

The advantages of clean liquids, especially oil, in machines include:

- Minimized maintenance time and costs

- Maximized performance and productivity

- Improved longevity of components and machinery

- Fewer stoppages in systems

- Reduced repairs and hardware replacements

All these benefits help save money, as fewer contaminants in fluids lead to energy savings and a longer machinery lifecycle. For instance, the cleaner the oil, the lower the oil temperature, the higher the oil viscosity, and the better the performance. Less maintenance time and fewer repairs also save on staff and hardware costs.

As we covered in our interview on oil contamination and analysis, oil loses its lubricating qualities when exposed to microparticles, moisture, and salt. This results in corrosion, additive degradation, and the formation of resins and deposits. Mechanical parts, such as valves, begin to jam, seize up, and wear out.

Fixing these parts is both costly and time consuming, so performing a cleanliness analysis is important to assess the contamination level in the oil. This is done by taking an oil sample using direct liquid filtration, then analyzing the contamination on the sample filter using a microscope-based technical cleanliness system. Below we will discuss some best practices for this sampling procedure.

Cleanliness Best Practices for Extracting a Fluid Sample from a System

When performing technical cleanliness inspections for fluid, cleanliness, external contamination, the sample point, and machine state all need to be considered when extracting a fluid sample from a system.

To prevent unwanted contamination during sample tests, think cleanliness at all steps! Here are some best practices:

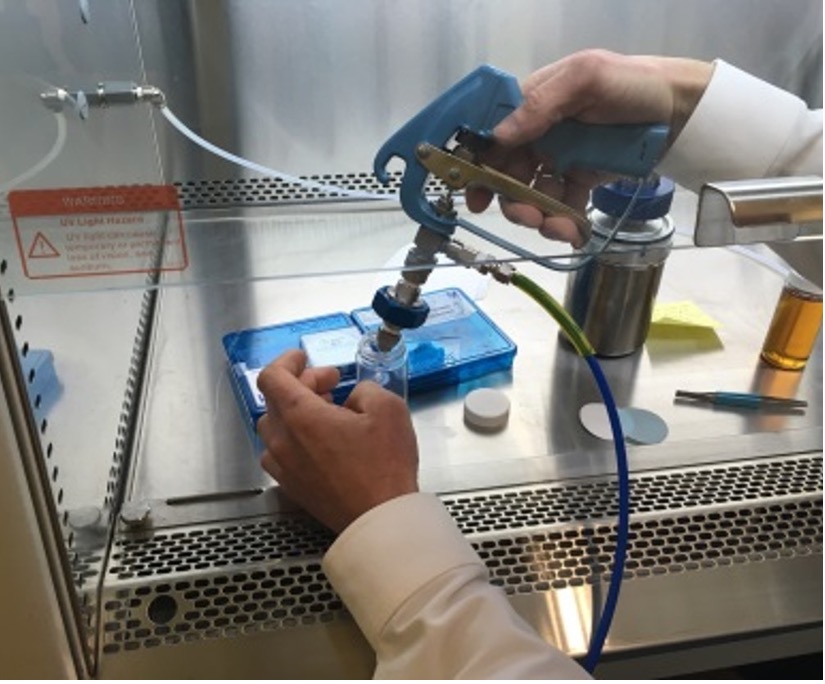

- Use a fume hood or safety cabinet when doing a sample test

- Clean the sampling equipment with a solvent such as heptane

- Wear lint-free clothing during the cleaning

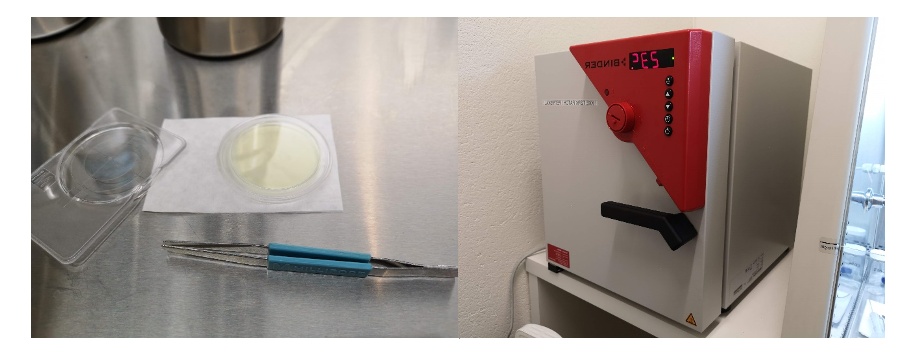

- Always transport and store the samples in a Petri slide after testing

Image courtesy of Europafilter Norge

Example of an Oil Sampling Procedure for Cleanliness Analysis

The following procedures are from an example oil sampling for a microscope-based technical cleanliness analysis.

When extracting an oil sample, it is important to make sure the oil sample is not contaminated by external impurities. Some best practices:

- Use a vacuum to extract the oil

- Do not run it through a pump that might contaminate the oil

- Extract from the middle of the tank, as there might be a concentration of contamination in the bottom or corners of the tank

Here is an example of an oil sampling procedure that keeps cleanliness in mind:

- Wet the funnel with a solvent such as heptane or clean petroleum and wipe the funnel with a lint-free cloth. Next, wet the mesh with the solvent and wipe with a lint-free cloth.

Image courtesy of Europafilter Norge

- Put the funnel in place, and wash the inside of the funnel and mesh. Now the oil sampling equipment is clean and ready to use.

Image courtesy of Europafilter Norge

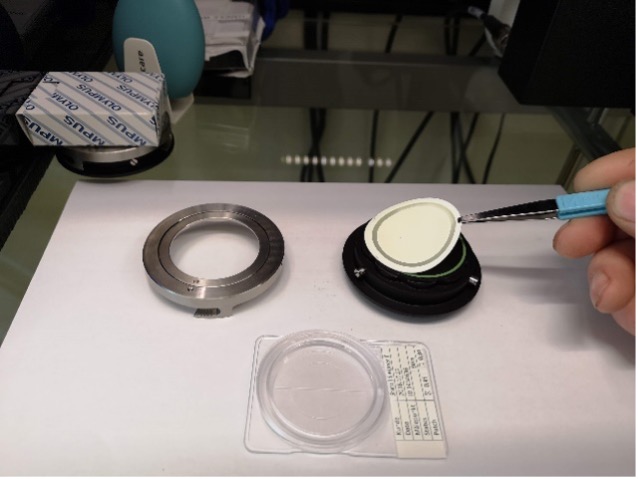

- Remove the funnel and place a filter membrane on the mesh screen. The usual filter membranes for oil analysis are made of cellulose nitrate and have a pore size of around 0.8 µm. Now the system is ready for filtering.

- Pour the oil sample into the funnel (about 2 ml to 100 ml depending on the suspected particle contamination). Begin to create a vacuum inside the flask to draw the liquid through the filter.

Image courtesy of Europafilter Norge

- Fill the sample bottle one-third full with the solvent. Shake the bottle and pour it into the funnel.

- When the sample level has dropped to the narrow end of the funnel, wash the inner walls of the funnel.

- When all of the sample is drawn through the sample filter, let it rest for a short while before removing the funnel.

- Remove the sample filter and dry it under a hood or in a drying oven. Place the sample filter in a Petri dish and mount the membrane on the filter holder.

Images courtesy of Europafilter Norge

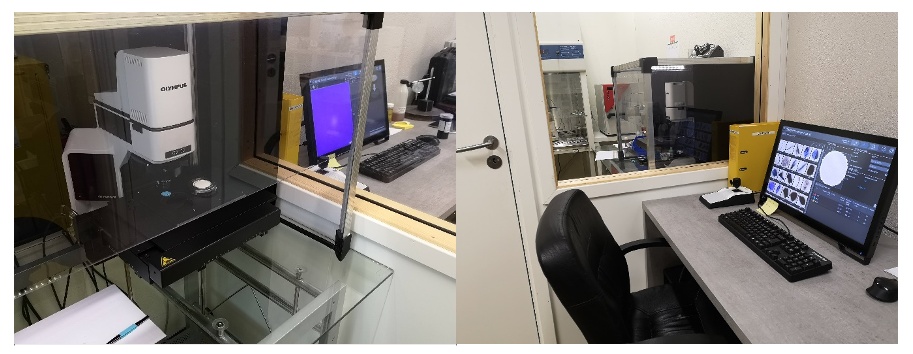

- Consider placing the microscope system under a hood to prevent unwanted contamination on the sample and collection of dust on the equipment. In this example, the microscope is placed inside a lab cleanroom with the workstation and joystick set up outside of the lab. Place the microscope in consistent light to prevent unwanted shading in the images.

Dedicated Accessories for Fluid Cleanliness Inspection

Our OLYMPUS CIX100 technical cleanliness inspection system offers dedicated sample holders to perform direct liquid filtration. These sample holders are available in diameters of 25 mm, 47 mm, and 55 mm, as well as white or black backgrounds to suit the application.

If a solvent was used to filter the liquid, using sample holders with a black background is recommended because these are largely inert to solvents. To simplify the analysis, the software of the CIX100 system automatically loads the appropriate settings when the operator selects the sample type.

Sample holders with a black background in diameters of 25 mm (left), 47 mm (middle), and 55 mm (right) are available for direct liquid filtration in a microscope-based cleanliness analysis

You can see how easy it is to mount a sample holder and start the inspection in the video below:

Learn More about Technical Cleanliness Inspections

To learn more about our microscope system and sample holders for technical cleanliness inspections of fluids and oil, reach out to us with any questions. We will also be continuing our series of posts on the different types of sampling methods. Look out for our next one on tape lift sampling!

Related Content

Common Sampling Techniques for Technical Cleanliness Inspections

Oil Contamination and Analysis—Expert Insights on an Invisible Problem

Analyzing Oil Cleanliness in Power Generation Plants Using the CIX100 System