Inspecting pipe welds is a demanding enough job without throwing cumbersome, complicated scanning equipment into the mix. When we designed the AxSEAM™ scanner, we focused on simplifying every aspect of longitudinal scanning for NDT inspectors.

The feedback from users has been positive, confirming that the scanner eases inspection as intended. You can read this customer review as well as this one to learn more.

There were two innovations introduced on the AxSEAM scanner that we realized could easily be transferred over to our other scanner models. The first to benefit: the HSMT-Flex™ scanner, our popular girth weld scanning system.

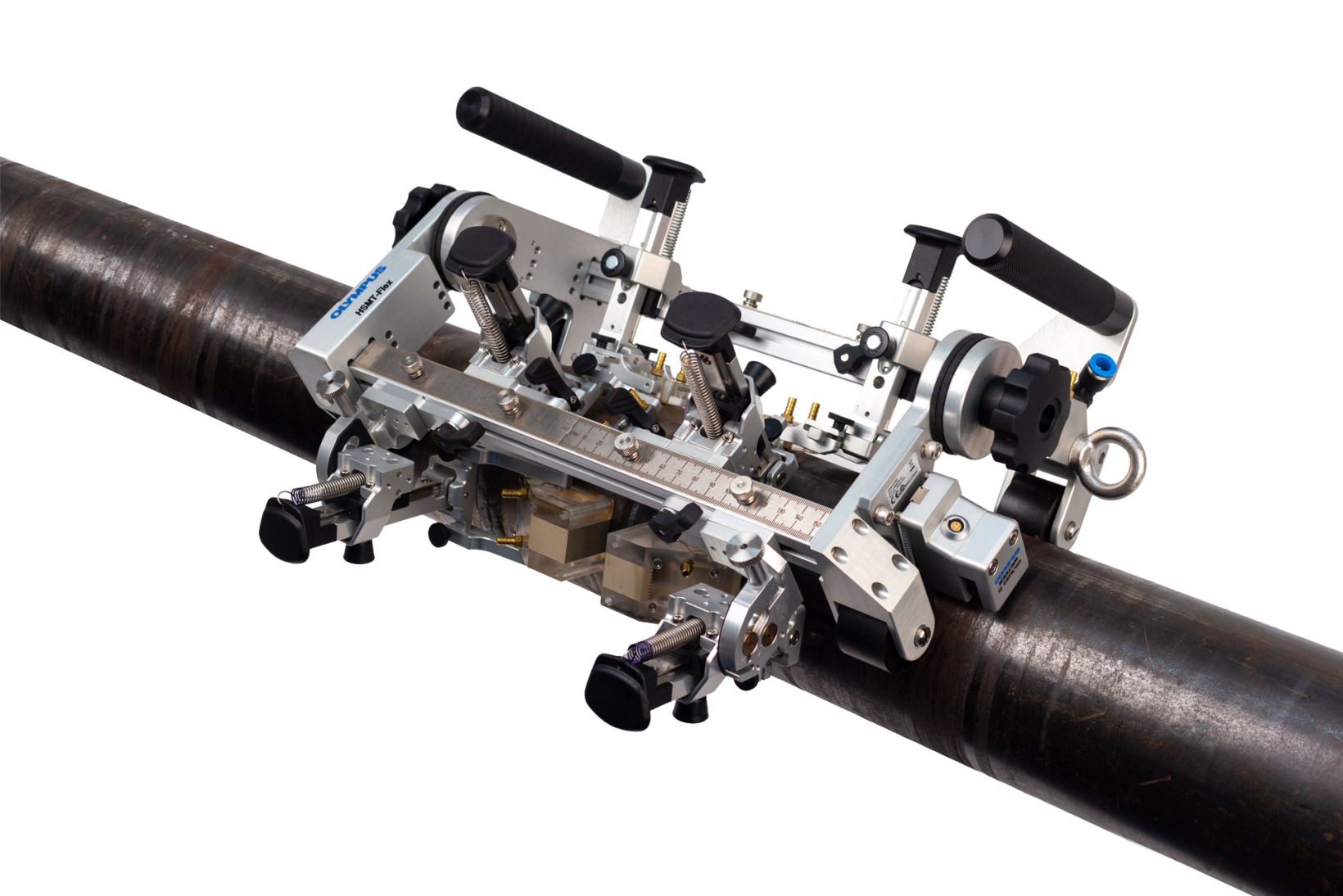

The HSMT-Flex scanner is a field-proven girth weld testing tool used by pipeline inspectors for well over a decade. Designed to ease circumferential scanning, the articulated scanner enables steady and reliable one-axis encoded ultrasonic and phased array (PA) inspection of welds on pipes 4.5 in. OD (114.3 mm OD) and up.

Now, every HSMT-Flex scanner we manufacture features these improvements:

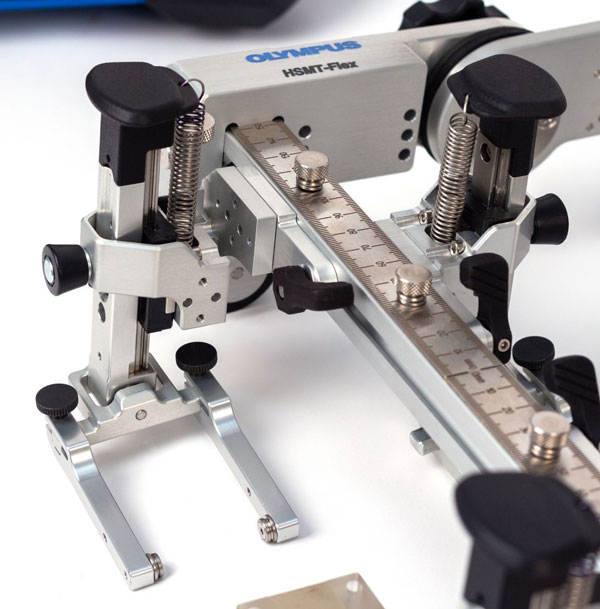

- Optimized spring-loaded probe holders with tool-free adjustments

- Laser light guide to ease alignment with the weld centerline (optional)

Retrofit kits of these probe holders and the laser guide are also available so current owners of the HSMT-Flex scanner can upgrade their scanning experience.

Minimize the Time and Effort Spent Configuring PA and UT Probes

When on site, you’ll save time setting up and adjusting the scanner’s probes thanks to the redesigned probe holders borrowed from the AxSEAM scanner.

You don’t need any tools to install or change the probes and wedges. The same goes for adjusting the index offset and contact pressure on the pipe’s surface.

Some of its tool-free operations:

- Slide open and close the fork (to insert the probe and wedge)

- Raise and lower the probe holder, and maintain it in the raised position with its handy latching system

- Slide the holders to set a specific probe center separation (PCS)

- Change the probe holder spring tension

All these adjustments are easily accomplished by manipulating the appropriate thumb screw or knob. The fork is compatible with a wide range of wedge widths, so you can quickly and easily install the wedge and probe combination that performs best for your needs.

Acquire the PAUT Data You Need the First Time Around and Avoid Rescanning

The scanner comes equipped with four probe holders but can accommodate a total of eight probes with four optional probe holders. You can use combinations of PA, time-of-flight diffraction (TOFD), and conventional UT probes to increase your detection capabilities and inspection efficiency.

Maintaining optimal pressure on the pipe surface, the probe holders’ springs and pivot mechanisms help ensure good coupling and limit mechanical play to maximize your signal integrity. Three easily exchangeable spring-tensions options are provided.

You can further increase the reliability and consistency of your ultrasonic data acquisition using the optional laser pointer to guide you. The laser pointer helps you keep centered over the weld line as you scan to make sure that the planned weld coverage is respected throughout the entire scan and no defects are missed.

True Simplicity, Proven Reliability so You Can Scan with Confidence

Reliable and robust, the HSMT-Flex scanner and its new probe holders are built to withstand the rigors of girth weld inspection in the field. This durability helps protect it from damage and minimizes downtime due to malfunctioning parts. Its ruggedness, ease of use, and features that support high-quality data acquisition can improve your inspection efficiency, so you get your jobs done faster and frustration free.

Learn more about the HSMT-Flex circumferential weld scanner at www.olympus-ims.com/scanners/hsmt-flex.

Related Content

Master Pipe Weld Scanning with This Versatile Tool

Ultrasonic Testing of Carbon Steel Plates and Pipes - NDT

Get In Touch

.jpg?rev=3652)