Background

Industrial videoscopes are commonly used for visual inspection of inner areas of various infrastructure equipment as well as industrial products. Familiar examples cover a broad range from monitoring of home pipings or ducts of water/sewerage, gas and air conditioners to quality check of automobile components. They are also used for visual inspection of large equipment such as airplane engines and electricity generator turbines without dismantling those. Thus, industrial videoscopes play important roles to support safety and security from behind the scenes. Particularly, videoscopes are the requisite equipment for inspection of heat exchangers.

Just as the name suggests, a heat exchanger is used “to heat cold object" and “to cool heated object". For instance, it produces steam to drive an electricity generator turbine as well as it cools steam behind turbine for condensation. Indeed, it is a backseat player working in oppressive conditions.

Typically, tube heat exchanger consisting of a series of thin tubes, whereas plate heat exchanger consisting of grooved plates. They are well-known types of heat exchanger structures. Videoscopes are often used to maintain tube heat exchangers.

Feature of Tube Heat Exchangers

A tube heat exchanger consists of many tubes (piping) and a shell to house the piping. Due to opposite actions of heating and cooling, heated side expands while cooled side shrinks; thus cracks and/or pipe wall thinning are caused. Number of tubes may reach several tens or several hundreds which are tightly arranged in good order. Tubes come in a variety of length; TEMA (Tubular Exchanger Manufacturers Association, Inc) standardizes a type consisting of straight tubes of 240 inches (Approx. 6m) with U shaped end joints, as a typical structure. Videoscope inspection is performed to visually check inner walls of heat exchanger tubes so that the timing of repair or replace can be judged as appropriate. Olympus supplies videoscopes suitable for inspection of the 240 inch straight tubes with U shaped joints.

Inspection Objects of Heat Exchangers

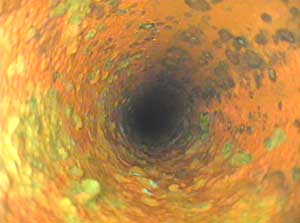

During videoscope inspection of heat exchangers, inner wall of tubes are typically inspected. Water, which transfers heat, contains calcium and other components which accumulate in welded area and/or U shaped joints. Heat may cause corrosion wastages of pipe. These are visually inspected with a videoscope so that the timing of replacement or scrubbing can be judged appropriately. In plants, inspection of the whole equipment is performed while it shut down for a certain period for regular maintenance service.

In such inspections, a number of similar tubes are inspected and pictures of defective area are taken. Through these inspections, the defective parts can be replaced before serious incidents are developed. During videoscope inspections, 2 persons may make a team in which one person operates videoscope while another person records the tube numbers inspected as well as the information about defective areas. In such conditions, due to numerous inspection objects, the records may lose consistency during inspection to degrade the reliability of precious inspection results.

| Visual inspection inside a heat exchanger tube | Videoscope picture of inner wall of a heat exchanger tube |

Picture and Inspection Details are Recorded Concurrently

As mentioned above, in the conventional inspection manner, the inspection pictures and textual information are retained separately to be matched later. Consequently, it takes long time to match pictures and textual information. It is even difficult to clarify the inspection details in some cases.

In a novel inspection practice which Olympus proposes, thanks to the inspection support software system installed in videoscopes, the pictures and relevant inspection details are concurrently recorded. Accordingly, not only one person can inspect and record relevant information by himself/herself, but also reports are automatically prepared when record data is simply uploaded to a PC. Traditionally, it takes longer time for report preparation than actual inspection work. The industrial videoscope and inspection support software system, InHelp from Olympus, are receiving high evaluation for the advantage of greatly reducing report preparation time which allows reduction of total inspection costs.

Enabling more Reliable Inspection in Combination with NDT Equipment

For inspection of heat exchanger equipment, leverage of NDT equipment is broadly practiced as well. Ultrasonic flaw detectors are useful to detect inner-wall flaws by probing from outside of tubes. When such detected flaws are visually inspected through a videoscope, it is possible to assess significance of the damage more precisely. As such, combination use of NDT equipment and industrial videoscopes enables more reliable inspections.