Olympus Industrial Resources

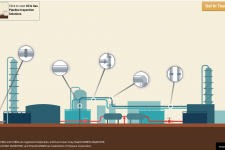

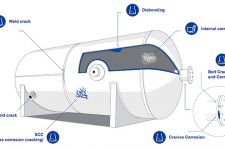

TutorialsOur tutorials provide comprehensive traning on a range of technologies. These trainings are in course format and feature interactive content. These tutorials make great training students or new hires. We also offer on-site classes. Contact your local rep if you’re interested. | |||||

|

| ||||

|

| ||||