Micron-sized shape measurements using a laser microscope

Plastic bottle cap

(1) Application

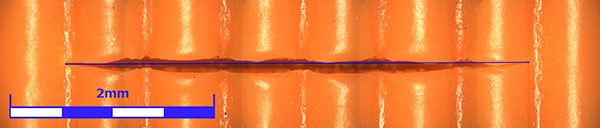

Plastic bottles are ubiquitous. Since they are beverage containers, their sanitation is strictly managed. Some bottle caps contain a small cut on the side called a vent hole, and it is designed to clean the drinking spout. When the cap has this hole, the screw area of the drinking spout can be cleaned by watering the cap after filling the bottle and tightening the cap. When the bottle’s content is heated to a high temperature, it causes the vent to open, allowing water into the hole. The water washes the screw spout and drains from the bottom of the cap. Because the size of the cut determines how much the hole opens, it is important to observe the cut’s size and condition.

(2) Olympus' solution

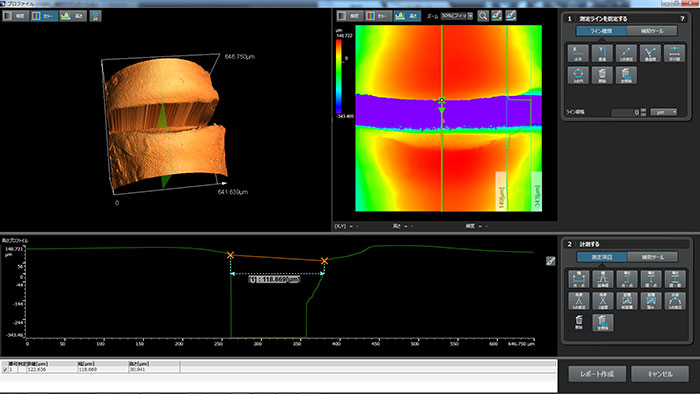

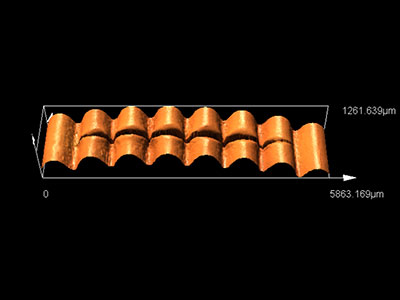

The LEXT OLS5000 3D scanning laser microscope uses a confocal optical system to combine multiple images with focused height information, enabling high-resolution, precise 3D profile measurements and clear, high-resolution images. Thanks to dedicated objective lenses with high numerical apertures and a dedicated optical system that maximizes the performance from the microscope’s 405 nm semiconductor laser, the OLS5000 system can capture the profile of a cut with a deeply plunging slope. Using the stitching mode, you can capture data for the cut beyond the microscope’s field of view. In addition to observation, the microscope also enables quantitative evaluation, including measurement of the width or length of the cut using high-precision data, which is effective for quality control.

Images

(1) Vent hole

(2) Microscopic imagery (Objective 10 × 5 × 1 lens lamination; effective field of vision: 5860 µm × 1260 µm)

(Objective 20×; effective field of vision: 640 µm)