Engine valve

Application

Valves are necessary in an internal combustion engine to ensure the proper fuel-air mixture intake or combustion gas exhaust, by closing the intake and exhaust ports of the combustion chamber. To ensure that each valve closes the associated port as completely as possible, the valve face contact surface must be polished to increase flatness. The flatness must be measured to determine if it is within tolerance.

A contact-type roughness tester has often been used to measure the contact surface flatness. However, the contact-type roughness tester can only present line roughness data, and requests for more reliable planar roughness data are increasing.

The Olympus solution

Roughness measurements made using the LEXT OLS5000 3D laser scanning microscope provide planar roughness data, which is more accurate than line roughness data alone.

Features of the product

- Since roughness is measured using the plane, more accurate roughness data is provided.

- Color images, laser images, and 3D profile data can all be obtained at the same time, expanding the range of analysis.

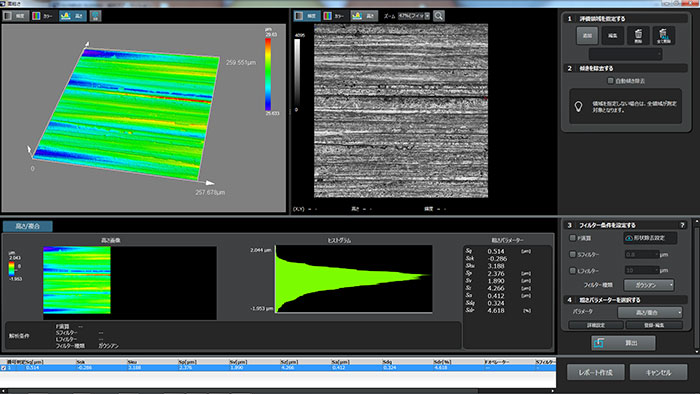

Images

Valve face contact surface

Planar roughness measurement of the valve face contact