Non-contact 3D surface profile measurement using a laser microscope

Expanded metal

1. Application

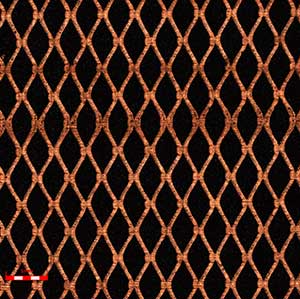

Expanded metal has a diamond-shaped ‘mesh’ structure created by slitting and stretching a metal plate in a press. This structure enables light, heat, sound, and air to pass through the expanded metal, and the structure’s mesh pattern has no joints, giving the metal superior mechanical strength (particularly in shear deformation stress). The thickness of the material plate and the size of the diamond-shaped pattern differ widely depending on the application. Expanded metal is used in internal and external building materials such as fences, automotive parts, external communication equipment, kitchen instruments, and farm equipment. When used as an arts and crafts supply, expanded metal typically has a mesh size of about 1 mm, and the plate is very thin (several hundred μm thick) and light. However, if the cut end is sharp or has burrs created during the process of slitting and stretching, users may be injured when they touch the expanded metal with bare hands. Therefore, it is important to observe the metal’s surface conditions, but visual observation is difficult due to the fineness of the cut end.

2. The Olympus solution

Olympus' LEXT 3D scanning laser microscope can be used as an optical microscope that enables users to easily switch from low to high magnification. Users also have the ability to acquire a high-resolution 3D surface profile from a specific area using the microscope’s laser. The LEXT microscope’s confocal optical system can create an all-in-focus image for reliable image data, and the dedicated optical system obtains maximum performance from the 405 nm laser, making it easy to determine if the cut end of the expanded metal has fine burrs. The microscope’s advanced features also make it simple to measure the height of any burrs that are located or analyze the roughness of a microscopic joint area. Small areas that could not be seen clearly with an optical microscope, such as edges, can be clearly observed with the LEXT microscope. The microscope’s stitching function makes it possible to view specimens with a wider field of view.

Images

Expanded metal viewed under the LEXT microscope. Objective lens 5X, zoom 1X |  An image showing the cut end of an expanded metal piece. Objective lens 20X, zoom 1X |