Steel Plant Image

Application

In steel plants, hydraulic oil pressure is required to drive certain production equipment. The hydraulic oil used in this equipment can become contaminated during operation, altering its chemical composition and affecting the equipment’s efficiency and ultimately shortening the use-life of both the hydraulic oil and the equipment. The acceptable level of particulate contamination is determined by international and company standards. A contamination management program complying with these standards enables steel plant operators to maintain their hydraulic oil in good condition. Such programs involve monitoring and analyzing hydraulic oil particulate contamination through regular technical cleanliness inspection. However, some contamination analysis methods, such as gravimetric analysis (using a lab balance) or particle counters, have inherent shortcomings that make them less precise:

- When contamination is analyzed using gravimetric analysis, the total mass of contamination can be identified, but size data for individual particles is unknown.

- Particle counters are incapable of both metal and nonmetal classification or classification according to shape. In addition, depending on the orientation of the contaminants in the oil, the particle count may be inaccurate.

Olympus' solution

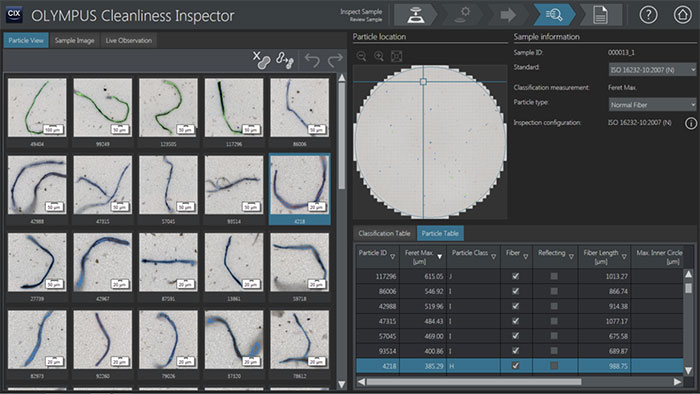

Analysis using the OLYMPUS CIX100 technical cleanliness inspection system

Features of the product

- With its high-performance industrial microscope and versatile, dedicated software, the OLYMPUS CIX100 system can obtain highly accurate data of the shape and size of each contaminant particulate.

- Using its unique optical system, the system detects both reflective and nonreflective particles, so metal and nonmetal contamination can be classified in one scan.

- The OLYMPUS CIX100 system complies with NAS1638/ISO4406, 4407/NFISO21018, NF E48-651, and 48-655 industrial standards. It also enables users to create their own classification settings.

Image

Contamination analysis image example