The Importance of Weld Inspection

The quality of welds is becoming increasingly important as customer expectations rise. Products and components are expected to be high quality and not fail unexpectedly. Component failures can lead to large financial consequences and potential safety issues that can often be avoided by following proper inspection techniques.

Inspecting welds can also reduce costs by detecting defects in the early stages of manufacturing. Catching defects earlier in the process enables manufacturers to correct them before the material is released to be used in the field. As a result, manufacturers can reduce the cost of customer returns, extend the life of components, and improve safety.

Eddy current testing is a reliable, quick, and inexpensive way to perform preventative maintenance and help ensure quality components.

Eddy Current Testing on Welds

In welding inspection, there is a need to detect surface-breaking defects. For magnetic material (e.g., carbon steel), generally magnetic particle inspection is used. However, eddy current inspection offers many advantages:

- No consumables used (e.g., ink and contrast paint)

- Can test areas with poor access

- No surface preparation required (e.g., paint does not need to be removed, saving time in preparation for the inspection and in any recoating of surfaces)

- Improved sensitivity: ability to detect smaller defects using specially developed weld probes

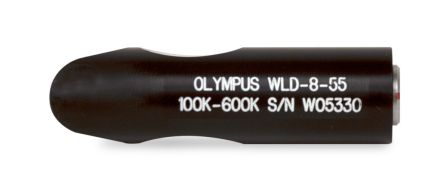

Weld Probe Applications

Weld probes are specifically developed to check welds for cracks and corrosion. Weld probes are used to inspect welds in a wide variety of equipment and infrastructure, including:

- Offshore platforms

- Buildings

- Bridges

- Amusement park rides

- Ships, boats, submarines, and other marine vessels

- Cranes

- Utility poles

- Aircraft

Weld probes are built with durability in mind so that they can handle the rough weld surface while still picking up any faults in the weld.