Application: Detection of stress corrosion cracking (SCC) in pressure containment equipment such as pipelines, using eddy current array testing.

Problem: Detection of anomalies in pipelines is essential to continued safe operation. Numerous catastrophic events have occurred due to anomalies created by manufacturing and environmental conditions. Stress corrosion cracking develops in carbon steel and stainless steel pipelines due to a combination of environmental factors including absolute hoop, tensile, and fluctuating stress. Other influential factors include material (steel) type, number of inclusions, surface

roughness, coating integrity, and soil pH.

Two types of SCC are found in pipelines: high pH (9 to 11) and near-neutral pH (6 to 8). General characteristics of both forms of SCC are as follows:

- Cracks are usually oriented in longitudinal direction but may exist in other orientations depending on the direction of applied stress.

- Occurrence in clusters consisting of several cracks to hundreds of cracks.

- Cracks tend to interlink to form long shallow flaws which may grow to cause ruptures.

- Fracture faces are covered with magnetite and carbonate films.

Eddy current array testing offers a number of advantages over alternate NDT techniques such as magnetic particle inspection:

- Minimal surface preparation needed as compared to magnetic particle testing.

- Rapid scanning of large surface areas.

- Determine approximate depth of the cracks detected.

- C-Scan imaging of the area scanned can be used for reporting and subsequent inspection comparison

- Selection of the deepest crack(s) within a cluster of cracks.

Equipment:

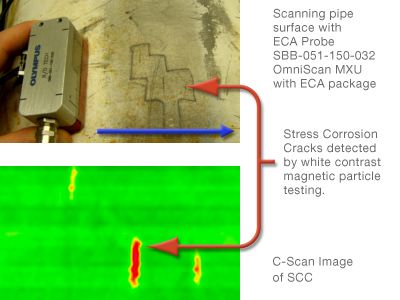

- OmniScan MX with Eddy Current Array Module

- Probe SBB 051-150-032, 150KHZ, 51mm coverage

- Encoder ABTX176C

- Calibration standard with EDM Notches at varying depths for comparison to aid depth estimation.

Procedure: Pipeline testing with the SBB 051-150 -032 for detection of SCC should be performed on clean smooth pipe. The pipe can be painted with epoxy paint up to .060" thick. Teflon tape should be applied to the contact surface of the probe to prevent wear. As always, a calibration standard should be used to determine detection capability and assure equipment performance. EDM notches are the preferred target reflectors for calibration. The probe should be placed on the

pipe oriented parallel to the long axis as shown in the photograph. The scan should be performed with an encoder attached to the probe.

The ONDT technical support team can provide a basic instrument setup as a starting point. Optimization will be required with the probe on the pipe to be inspected.

Conclusion

Eddy Current Array can be used to detect surface breaking cracks of the type caused by SCC in pipelines. This technique can be applied on both curved surfaces and flat plates. Both austenitic and ferromagnetic materials can be inspected. This technique can be considered environment friendly, unlike magnetic particle and dye penetrant examinations, since no waste is produced,